Content Menu

● Introduction to Scaffolding Couplers

● Types of Scaffolding Couplers

● Comparison of Right Angle Couplers with Other Couplers

>> Load-Bearing Capacity

>> Versatility and Flexibility

>> Cost and Efficiency

● Choosing the Right Coupler for Your Project

● Safety Considerations

>> Safety Standards

>> Best Practices

● Case Studies: Successful Use of Right Angle Couplers

● Example Project

● Future Developments in Scaffolding Technology

● Conclusion

● FAQ

>> 1. What is the primary use of scaffolding right angle couplers?

>> 2. How do swivel couplers differ from right angle couplers?

>> 3. What are putlog couplers used for?

>> 4. What is the role of sleeve couplers in scaffolding?

>> 5. How do girder couplers contribute to scaffolding systems?

● Citations:

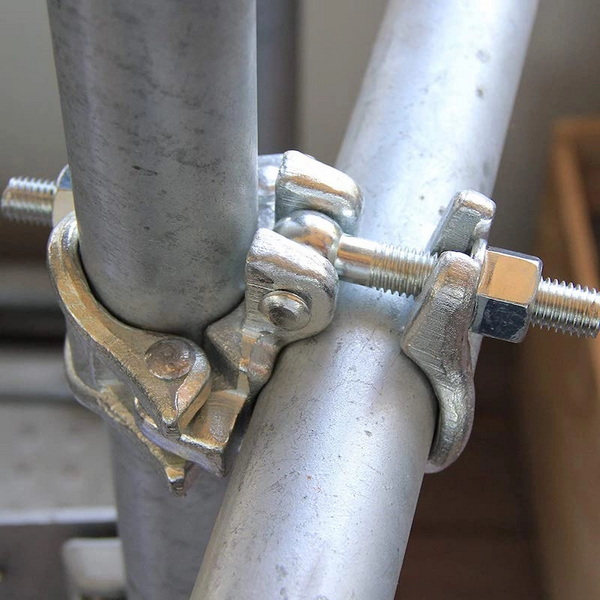

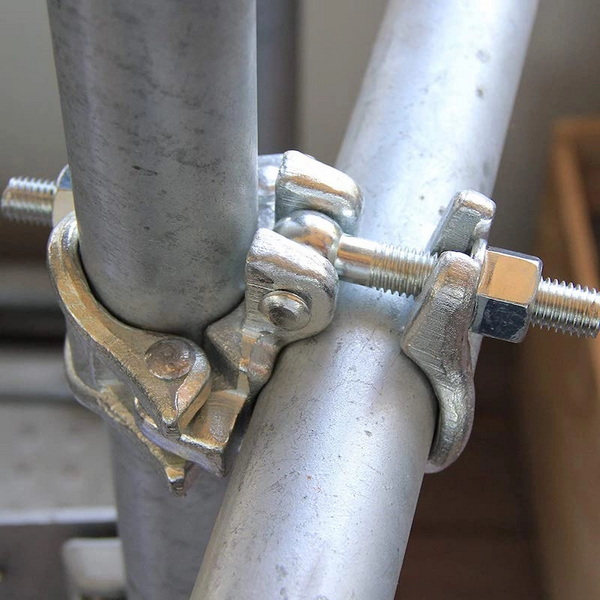

Scaffolding couplers are essential components in the construction industry, used to connect scaffolding tubes securely and efficiently. Among the various types of couplers, the scaffolding right angle coupler, also known as a double coupler, is one of the most common and critical for forming the basic framework of scaffolding structures. This article will delve into the comparison of right angle couplers with other types of couplers, highlighting their features, applications, and advantages.

Introduction to Scaffolding Couplers

Scaffolding couplers are designed to provide strong and stable connections between scaffolding tubes, ensuring the structural integrity and safety of the scaffold. The choice of coupler depends on the specific requirements of the project, including the type of scaffold, load capacity, and environmental conditions.

Types of Scaffolding Couplers

1. Right Angle Couplers (Double Couplers)

- Description: These couplers connect two scaffold tubes at a 90-degree angle, providing a strong and stable joint essential for the primary structural stability of the scaffold.

- Use: Primarily used in load-bearing applications, such as forming the basic framework or "standard" of the scaffold.

- Load Capacity: Can hold weights more than 30 KN, meeting the EN74 Class B standard.

2. Swivel Couplers

- Description: Allow for connections at any angle within a 360-degree range, making them ideal for complex scaffold configurations.

- Use: Used where flexibility is required, such as in curved or irregularly shaped scaffolds.

3. Putlog Couplers (Single Couplers)

- Description: Connect a scaffold tube to a horizontal member (putlog) or ledgers to standards with a single grip point.

- Use: Best for lighter, non-load-bearing connections, commonly used in putlog scaffolding systems.

4. Sleeve Couplers

- Description: Used to extend the length of scaffold tubes by connecting them end-to-end.

- Use: Essential for adjusting scaffold heights or lengths according to project requirements.

5. Girder Couplers

- Description: Designed for heavy-duty applications, typically used with girder scaffolding systems.

- Use: Ideal for large-scale construction projects requiring high load capacities.

6. BRC Couplers

- Description: Used to secure boards or platforms to the scaffold structure.

- Use: Essential for maintaining platform stability and preventing accidents in windy conditions.

Comparison of Right Angle Couplers with Other Couplers

Load-Bearing Capacity

- Right Angle Couplers: These couplers have a high load-bearing capacity, making them suitable for forming the main framework of scaffolding structures.

- Swivel Couplers: While versatile, swivel couplers may not match the load-bearing capacity of right angle couplers but are ideal for complex configurations.

- Putlog Couplers: Best suited for non-load-bearing applications due to their single grip point.

Versatility and Flexibility

- Right Angle Couplers: Limited to 90-degree connections, providing stability but less flexibility.

- Swivel Couplers: Offer flexibility with connections at any angle, making them suitable for complex scaffolding designs.

- Sleeve Couplers: Provide length adjustments but are not used for angle variations.

Cost and Efficiency

- Right Angle Couplers: Generally more cost-effective for standard scaffolding setups due to their widespread use and availability.

- Swivel Couplers: May be more expensive due to their versatility and complex design.

- Putlog Couplers: Cost-effective for non-load-bearing applications.

Choosing the Right Coupler for Your Project

The choice of scaffolding coupler depends on several factors:

- Load Requirements: For load-bearing applications, right angle couplers are preferred. For lighter applications, putlog couplers may suffice.

- Angle and Position Requirements: Swivel couplers are ideal for variable angles, while right angle couplers are best for fixed 90-degree connections.

- Environmental Conditions: In windy or high environments, consider using board retaining couplers to secure platforms.

Safety Considerations

Safety is paramount when constructing scaffolding. Ensuring that all couplers are properly secured and meet safety standards is crucial. Regular inspections should be conducted to check for any signs of wear or damage.

Safety Standards

- EN74 Standard: Specifies the requirements for couplers, including load capacity and durability.

- OSHA Guidelines: Provide detailed instructions on scaffold setup and safety precautions in the workplace.

Best Practices

- Regular Maintenance: Regularly inspect couplers for signs of wear or damage.

- Proper Installation: Ensure all couplers are correctly installed according to manufacturer instructions.

- Training: Ensure that all personnel handling scaffolding are properly trained.

Case Studies: Successful Use of Right Angle Couplers

Right angle couplers have been successfully used in numerous construction projects worldwide. For example, in large-scale building projects, these couplers are essential for forming the stable framework necessary for supporting heavy loads and ensuring worker safety.

Example Project

- Project Overview: A high-rise building construction project required a stable scaffolding system to support multiple levels of construction work.

- Use of Right Angle Couplers: These couplers were used extensively to form the main framework of the scaffold, ensuring stability and safety for workers.

- Outcome: The project was completed successfully without any major incidents related to scaffolding stability.

Future Developments in Scaffolding Technology

The scaffolding industry is continuously evolving with advancements in technology and materials. Future developments may include:

- Lightweight Materials: The use of lighter yet stronger materials could reduce the weight of scaffolding while maintaining or increasing load capacity.

- Automated Systems: Automated scaffolding systems could streamline setup and dismantling processes, improving efficiency and reducing labor costs.

Conclusion

Scaffolding right angle couplers are crucial for constructing stable and load-bearing scaffolding structures. While they offer strong connections at a fixed angle, other couplers like swivel and sleeve couplers provide flexibility and versatility. Understanding the specific needs of your project will help in selecting the most appropriate type of coupler.

FAQ

1. What is the primary use of scaffolding right angle couplers?

Scaffolding right angle couplers are primarily used to connect two scaffold tubes at a 90-degree angle, providing a strong and stable joint essential for the primary structural stability of the scaffold.

2. How do swivel couplers differ from right angle couplers?

Swivel couplers allow for connections at any angle within a 360-degree range, offering flexibility and versatility, whereas right angle couplers are limited to fixed 90-degree connections.

3. What are putlog couplers used for?

Putlog couplers are used for lighter, non-load-bearing connections, typically in putlog scaffolding systems where additional support is not necessary.

4. What is the role of sleeve couplers in scaffolding?

Sleeve couplers are used to extend the length of scaffold tubes by connecting them end-to-end, allowing for adjustments in scaffold heights or lengths.

5. How do girder couplers contribute to scaffolding systems?

Girder couplers are designed for heavy-duty applications, typically used with girder scaffolding systems to support large-scale construction projects requiring high load capacities.

Citations:

[1] https://shelterrc.com/scaffolding-couplers-types-a-comprehensive-guide/

[2] https://www.gd-scaffold.com/news/types-of-couplers-in-scaffolding.html

[3] https://patents.google.com/patent/WO2003091512A1/zh

[4] https://www.scaffoldclamps.com/blog/types-of-scaffolding-couplers

[5] https://caspiangroup.co.uk/different-types-of-scaffold-fittings/

[6] https://www.bbc.com/learningenglish/chinese/features/q-and-a/ep-200318

[7] https://www.gd-scaffold.com/news/what-is-the-difference-between-swivel-scaffolding-clamps-and-right-angle-scaffolding-clamps.html

[8] https://patents.google.com/patent/CN101053134B/zh

[9] https://www.wm-scaffold.com/scaffolding-coupler.html

[10] https://apacsafety.com/the-ultimate-guide-of-scaffolding-couplers/

[11] https://www.linkedin.com/pulse/comprehensive-guide-types-couplers-scaffolding-abhishek-mishra