Content Menu

● What Is a Scaffold Tower?

● Scaffold Tower Height: Definitions and Standards

● Maximum Heights: What the Regulations and Manufacturers Say

>> Typical Maximum Heights

>> Manufacturer Specifications

>> Regulatory Guidelines

● Factors Affecting Scaffold Tower Height

● Safety Guidelines for High Scaffold Towers

● Step-by-Step: Building a Scaffold Tower (with Diagrams and Video)

● Real-World Examples and Extreme Cases

>> Standard Use

>> Specialized Towers

>> Practical Limits

>> Case Study: High-Rise Window Cleaning

>> Case Study: Industrial Maintenance

● International Standards and Regulations

>> United Kingdom (EN 1004)

>> United States (OSHA)

>> Australia and New Zealand

>> Key Takeaway

● Troubleshooting Common Scaffold Tower Issues

>> Uneven Ground

>> Tower Swaying

>> Difficulty Assembling Components

>> Weather Hazards

>> Overloading

● Innovations and the Future of Scaffold Tower Technology

>> Lightweight Materials

>> Modular Designs

>> Digital Safety Systems

>> Robotics and Automation

● Conclusion

● FAQ

>> 1. What is the difference between platform height and working height?

>> 2. Can I build a scaffold tower higher than 12 meters?

>> 3. Are there different height limits for indoor and outdoor scaffold towers?

>> 4. What safety equipment is required for high scaffold towers?

>> 5. How often should scaffold towers be inspected?

Scaffold towers are indispensable in modern construction, maintenance, and industrial projects, enabling workers to safely access elevated areas. But one crucial question is often asked by professionals and DIY enthusiasts alike: How high can a scaffold tower go? The answer is more complex than a simple number-it involves regulations, engineering, environmental factors, and safety protocols. This comprehensive guide explores every aspect of scaffold tower height, supported by diagrams, real-world case studies, and expert advice.

What Is a Scaffold Tower?

A scaffold tower, also known as a tower scaffold or mobile access tower, is a modular, free-standing structure assembled from frames, braces, platforms, and stabilizers. Unlike traditional scaffolding, which is often fixed to a building, scaffold towers are designed for mobility and flexibility, making them ideal for a wide range of tasks at height.

Scaffold Tower Height: Definitions and Standards

Understanding Scaffold Tower Height Terms:

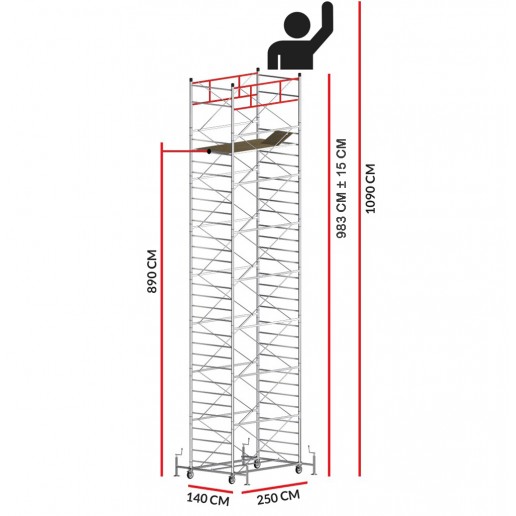

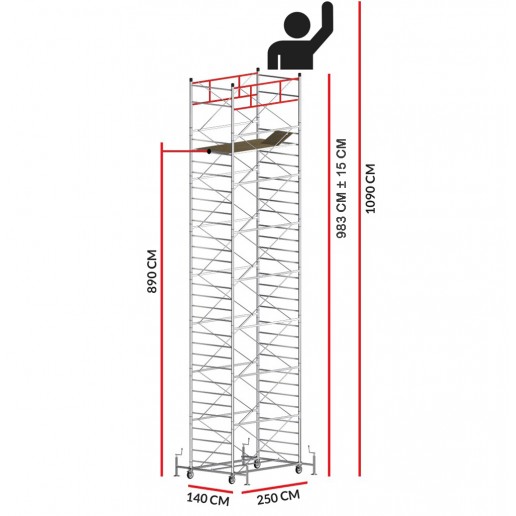

- Platform Height: The vertical distance from the ground to the highest standing platform. This is the actual height where workers stand and perform tasks.

- Working Height: The maximum height a worker can safely reach from the platform, typically calculated as platform height plus 2 meters (to account for a person's reach).

| Term | Definition |

| Platform Height | Height from ground to the top platform |

| Working Height | Platform height + 2 meters (approximate reach) |

Maximum Heights: What the Regulations and Manufacturers Say

Typical Maximum Heights

- Standard Scaffold Towers: Most scaffold towers built with typical components can reach a maximum platform height of 10 to 12 meters (approximately 33 to 39 feet).

- Working Height: With a platform height of 12 meters, the working height can be up to 14 meters (about 46 feet).

“A scaffold tower built with typical components can achieve a maximum height of around 10 to 12 meters. Scaffold towers are available in various heights from 0.6 meters to 12 meters.”

Manufacturer Specifications

- Always refer to the manufacturer's guidelines for the specific model, as each system is designed and tested under particular conditions.

- Some heavy-duty or specialized systems may exceed standard heights, but additional supports, tie-ins, or bracing are required.

Regulatory Guidelines

- The Work at Height Regulations (UK) and OSHA (US) provide strict rules for scaffold tower assembly, use, and inspection, especially as height increases.

- For mobile towers, the maximum free-standing height is generally 12 meters indoors and 8 meters outdoors, unless tied to a structure.

Factors Affecting Scaffold Tower Height

Several variables influence how high a scaffold tower can safely go:

- Base Dimensions: A wider base allows for greater height. A common guideline is a 4:1 height-to-base width ratio, but always check the manufacturer's instructions.

- Use Conditions: Indoor towers can be taller than outdoor ones, as wind and weather affect stability.

- Tie-Ins and Supports: Towers tied to a building or with additional stabilizers can safely reach greater heights.

- Component Quality: Only use certified, undamaged components designed for your system.

- Ground Conditions: The surface must be firm and level to prevent tipping or collapse.

- Load Capacity: The number of workers, tools, and materials on the platform also impacts maximum safe height.

Safety Guidelines for High Scaffold Towers

Safety is paramount when working at height. Key practices include:

- Risk Assessment: Conduct a thorough assessment before assembly.

- Proper Assembly: Follow the manufacturer's instructions step by step.

- Regular Inspections: Inspect the tower before each use and periodically during use.

- Guardrails and Toeboards: Install at all platforms to prevent falls and falling objects.

- Weather Precautions: Avoid use in high winds or storms, especially for outdoor towers.

- Training: Only trained, competent personnel should assemble, modify, or dismantle towers.

- Personal Protective Equipment (PPE): Use helmets, non-slip footwear, and harnesses where required.

Step-by-Step: Building a Scaffold Tower (with Diagrams and Video)

Step 1: Attach cross braces to the first set of frames.

Step 2: Install casters (wheels) and secure them.

Step 3: Add the first platform.

Step 4: Stack the next set of frames and secure with cross braces.

Step 5: Continue adding platforms and braces as needed.

Step 6: Install guardrail posts and guardrails at the top platform.

Step 7: Add stabilizers or outriggers for extra support.

Step 8: Inspect the entire structure before use.

Real-World Examples and Extreme Cases

Standard Use

Most construction and maintenance projects use towers between 3 and 12 meters in platform height. For example, painting a two-story house or repairing a commercial building facade.

Specialized Towers

The world's tallest free-standing tower scaffold, the SkyScraper by Safway Services, can reach 550 feet (167.64 meters), but this is a highly specialized, sectional system used for unique industrial projects.

Practical Limits

For most users, especially in residential or commercial settings, a 6–7 meter tower is sufficient for two-story buildings. Exceeding this height is rare and requires professional oversight.

Case Study: High-Rise Window Cleaning

In major cities, specialized scaffold towers are used for window cleaning on skyscrapers. These towers are often tied to the building at regular intervals and feature advanced safety systems, including wind sensors and emergency descent mechanisms.

Case Study: Industrial Maintenance

In oil refineries and power plants, scaffold towers are custom-built to access complex machinery and pipework. Here, towers may be assembled to heights above 20 meters but are always anchored and designed by certified engineers.

International Standards and Regulations

United Kingdom (EN 1004)

- EN 1004 is the European standard for mobile access and working towers.

- Specifies maximum heights, load classes, and safety features.

- Requires guardrails, toeboards, and safe access at all levels.

United States (OSHA)

- OSHA 1926 Subpart L covers scaffolding requirements.

- Mandates regular inspections, fall protection, and training.

- Specifies that the height-to-base width ratio for mobile scaffold towers must not exceed 4:1 unless guyed or otherwise stabilized.

Australia and New Zealand

- AS/NZS 1576 sets out requirements for scaffold tower design, assembly, and use.

- Emphasizes wind loading, platform access, and stability.

Key Takeaway

Always check local regulations and standards before erecting a scaffold tower, as requirements may vary by country and region.

Troubleshooting Common Scaffold Tower Issues

Uneven Ground

Solution: Use adjustable legs or base plates to level the tower. Never use bricks or makeshift supports.

Tower Swaying

Solution: Add stabilizers, outriggers, or tie the tower to a solid structure. Reduce platform height if necessary.

Difficulty Assembling Components

Solution: Inspect all parts for damage or deformation. Only use components designed for your specific tower system.

Weather Hazards

Solution: Dismantle or lower the tower in high winds. Use wind gauges and follow manufacturer's wind speed limits.

Overloading

Solution: Respect the maximum load rating for platforms and towers. Distribute weight evenly and avoid stacking materials.

Innovations and the Future of Scaffold Tower Technology

Lightweight Materials

Modern scaffold towers use high-strength aluminum alloys, reducing weight and making assembly easier without sacrificing strength.

Modular Designs

New systems allow for rapid assembly and disassembly, with color-coded components and tool-free connections.

Digital Safety Systems

Some advanced towers feature integrated sensors that monitor load, wind speed, and structural integrity, sending alerts to workers' smartphones or site managers.

Robotics and Automation

The future may see robotic scaffold towers that self-assemble or adjust height remotely, further improving safety and efficiency.

Conclusion

The maximum height a scaffold tower can safely reach depends on its design, base dimensions, use environment, and strict adherence to manufacturer and regulatory guidelines. For standard modular towers, the maximum platform height is typically 10–12 meters (33–39 feet), with a working height up to 14 meters (46 feet). Exceeding these heights requires additional tie-ins, supports, and professional oversight.

Safety must always come first. Never attempt to exceed the recommended heights or modify towers beyond their intended use. Regular inspections, proper training, and compliance with all safety regulations are essential to prevent accidents and ensure efficient, productive work at height.

FAQ

1. What is the difference between platform height and working height?

Platform height is the distance from the ground to the top platform where workers stand. Working height is the platform height plus approximately 2 meters, representing the maximum height a worker can reach with their arms extended.

2. Can I build a scaffold tower higher than 12 meters?

Generally, 12 meters is the maximum for standard modular towers. Higher towers require tie-ins to a building, additional stabilizers, and must strictly follow manufacturer and regulatory guidelines.

3. Are there different height limits for indoor and outdoor scaffold towers?

Yes. Indoors, towers can typically be built up to 12 meters free-standing. Outdoors, the safe maximum is usually 8 meters unless the tower is tied to a structure, due to wind and weather risks.

4. What safety equipment is required for high scaffold towers?

Guardrails, toeboards, stabilizers, and sometimes fall arrest systems are required. Regular inspections and risk assessments are also mandatory. All users must be trained and follow safety protocols.

5. How often should scaffold towers be inspected?

Scaffold towers should be inspected before each use, after any event that could affect stability (such as strong winds), and at regular intervals during use. Inspections must be documented and performed by a competent person.