Content Menu

● Introduction to Scaffolding Ringlock

● Key Components of Ringlock Scaffolding

● Durability and Maintenance

● Maintenance Guidelines

● Adaptability and Versatility

● Applications of Ringlock Scaffolding

● Factors Influencing Lifespan

● Impact of Environmental Conditions

● Advanced Features of Ringlock Scaffolding

>> Modular Design

>> Safety Features

● Cost-Effectiveness

● Comparison with Other Systems

● Case Studies

● Example Projects

● Conclusion

● FAQ

>> 1. What Materials Are Used in Ringlock Scaffolding?

>> 2. How Does Ringlock Scaffolding Handle Harsh Conditions?

>> 3. What Are the Key Components of Ringlock Scaffolding?

>> 4. How Often Should Ringlock Scaffolding Be Inspected?

>> 5. Can Ringlock Scaffolding Be Used for Complex Structures?

● Citations:

Scaffolding Ringlock systems are renowned for their durability and versatility in construction projects. These systems are designed to withstand harsh conditions, making them ideal for use in various environments. In this article, we will delve into the factors that influence the lifespan of Ringlock scaffolding in challenging conditions and explore how its design and materials contribute to its longevity.

Introduction to Scaffolding Ringlock

Scaffolding Ringlock systems are constructed from high-strength steel, often coated with hot-dip galvanization to enhance corrosion resistance. This material choice ensures that the scaffolding can endure harsh weather conditions and heavy usage without compromising its structural integrity.

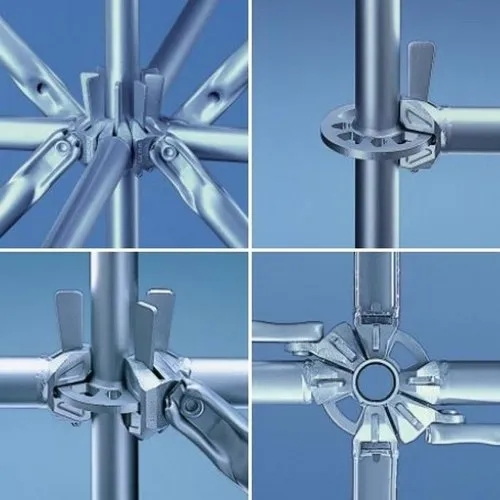

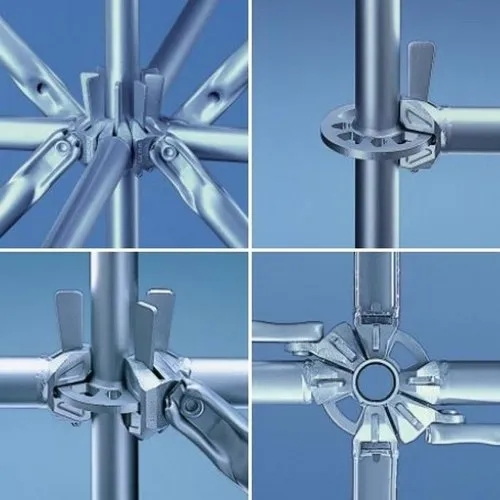

Key Components of Ringlock Scaffolding

The Ringlock system consists of several key components, including:

- Standards: These are the vertical posts that provide the main support for the scaffolding.

- Ledgers: Horizontal beams that connect the standards, forming the framework of the scaffolding.

- Diagonal Braces: These provide additional stability to the structure.

- Screw Jacks: Used to level the scaffolding on uneven surfaces.

Durability and Maintenance

Ringlock scaffolding's durability is largely due to its robust construction and protective coating. The hot-dip galvanization process ensures that the steel components resist corrosion, extending the lifespan of the scaffolding even in environments with high moisture or salt exposure.

Maintenance Guidelines

To maximize the lifespan of Ringlock scaffolding, regular maintenance is crucial. This includes:

- Inspection: Regularly inspect the scaffolding for signs of wear or damage.

- Cleaning: Clean the scaffolding to prevent dirt buildup, which can lead to corrosion.

- Repairs: Address any damage promptly to prevent further deterioration.

Adaptability and Versatility

Ringlock scaffolding is highly adaptable, suitable for various construction projects, including circular, curved, and irregular structures. Its modular design allows for easy customization to meet specific project requirements.

Applications of Ringlock Scaffolding

- Construction Sites: Residential, commercial buildings, and infrastructure projects.

- Industrial Settings: Shipyards, petrochemical plants, and more.

- Event Staging: Concerts and large events requiring temporary structures.

Factors Influencing Lifespan

Several factors can influence the lifespan of Ringlock scaffolding in harsh conditions:

- Material Quality: The use of high-strength steel and hot-dip galvanization significantly enhances durability.

- Environmental Conditions: Exposure to extreme weather, saltwater, or chemicals can affect longevity.

- Usage Patterns: Frequent assembly and disassembly can lead to wear on components.

Impact of Environmental Conditions

Harsh environmental conditions, such as high humidity or salt exposure, can accelerate corrosion if the scaffolding is not properly maintained. Regular inspections and maintenance are essential to mitigate these effects.

Advanced Features of Ringlock Scaffolding

Modular Design

The modular nature of Ringlock scaffolding allows for easy assembly and disassembly, making it efficient for projects with changing requirements. This flexibility also reduces the need for specialized tools, simplifying the construction process.

Safety Features

Ringlock scaffolding is designed with safety in mind, featuring secure locking mechanisms that ensure stability and prevent accidental disassembly. This enhances worker safety and reduces the risk of accidents on site.

Cost-Effectiveness

Despite its durability and versatility, Ringlock scaffolding is often more cost-effective than other scaffolding systems. The ability to reuse components across multiple projects significantly reduces long-term costs.

Comparison with Other Systems

When compared to other scaffolding systems, Ringlock stands out for its ease of assembly, durability, and adaptability. These advantages make it a preferred choice for many construction projects.

Case Studies

Ringlock scaffolding has been successfully used in numerous high-profile projects worldwide, demonstrating its reliability and performance in challenging environments.

Example Projects

- Infrastructure Development: Used in the construction of bridges and highways.

- Industrial Maintenance: Employed in shipyards and petrochemical plants for maintenance and repair work.

- Event Staging: Utilized for temporary structures at large events like concerts and festivals.

Conclusion

Ringlock scaffolding is designed to provide a durable and versatile solution for construction projects, even in harsh conditions. Its longevity is influenced by factors such as material quality, environmental exposure, and maintenance practices. By adhering to proper maintenance guidelines and selecting high-quality components, users can maximize the lifespan of their Ringlock scaffolding systems.

FAQ

1. What Materials Are Used in Ringlock Scaffolding?

Ringlock scaffolding is primarily made from high-strength steel, often coated with hot-dip galvanization to protect against corrosion.

2. How Does Ringlock Scaffolding Handle Harsh Conditions?

Ringlock scaffolding is designed to withstand harsh conditions due to its robust construction and protective coating. Regular maintenance is crucial to ensure longevity.

3. What Are the Key Components of Ringlock Scaffolding?

The key components include standards, ledgers, diagonal braces, and screw jacks. These components work together to provide a stable and adaptable scaffolding system.

4. How Often Should Ringlock Scaffolding Be Inspected?

Ringlock scaffolding should be inspected regularly, ideally before each use, to ensure that all components are in good condition and free from damage.

5. Can Ringlock Scaffolding Be Used for Complex Structures?

Yes, Ringlock scaffolding is highly adaptable and can be used for complex structures, including circular, curved, and irregular designs.

Citations:

[1] https://www.tytruss.com/newsclass_2/Steel-Ringlock-Scaffolding-Benefits-Safety.shtml

[2] https://www.youtube.com/watch?v=C7Zfpfb35yg

[3] https://www.sohu.com/a/793967857_120288885

[4] https://scaffoldingrentalandsales.com/scaffolding/ring-lock-scaffolding/

[5] https://www.youtube.com/watch?v=rUq_iPVCkXg

[6] https://www.alibaba.com/product-detail/Layher-ringlock-scaffolding-ringlock-scaffolding-system_60672151058.html

[7] https://apacsafety.com/ultimate-guide-of-ringlock-scaffold/

[8] https://www.youtube.com/watch?v=tnec3rM5kQE

[9] https://www.youtube.com/watch?v=TLTqU1Jce2k