Content Menu

● Understanding the Components and Their Impact on Cost

>> Standards (Verticals)

>> Ledgers (Horizontals)

>> Braces (Diagonals)

>> Platforms and Decks

>> Accessories

● Factors Influencing the Overall Cost of a Rosette Scaffolding System

>> Material Quality

>> Manufacturing Standards and Certifications

>> Supplier Reputation and Location

>> Project Size and Complexity

>> Labor Costs for Assembly and Dismantling

>> Transportation and Logistics

>> Maintenance and Repair Costs

>> Rental vs. Purchase

● Estimating the Cost: A Practical Approach

● Real-World Cost Examples

● Cost-Saving Strategies

● Conclusion

● FAQ

>> 1. What is the typical lifespan of a rosette scaffolding system?

>> 2. Is it more cost-effective to rent or buy a rosette scaffolding system?

>> 3. What safety certifications should I look for when purchasing a rosette scaffolding system?

>> 4. How does the rosette design contribute to cost savings?

>> 5. Can rosette scaffolding systems be adapted for use on uneven terrain?

● Citations:

Determining the cost of a rosette scaffolding system, also widely recognized as a ring lock scaffolding system, is not a straightforward process. Numerous variables impact the final price, including the project's scope, the system's quality, the supplier's pricing, and added services like delivery and assembly. This article aims to dissect these elements, providing a comprehensive guide to understanding the financial implications of investing in a rosette scaffolding system.

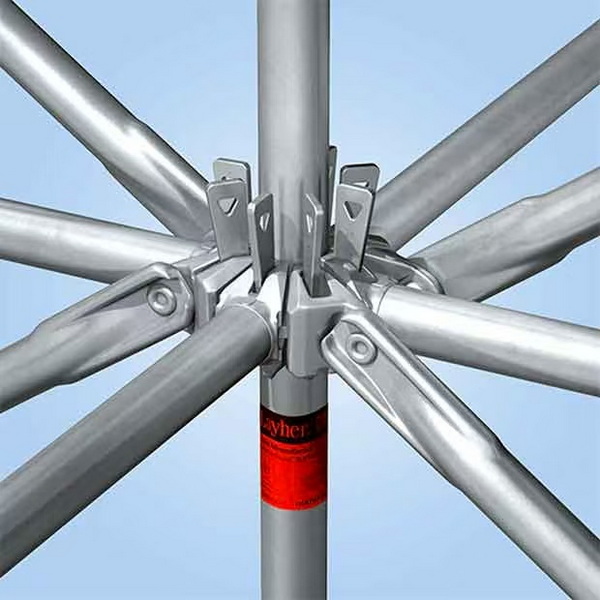

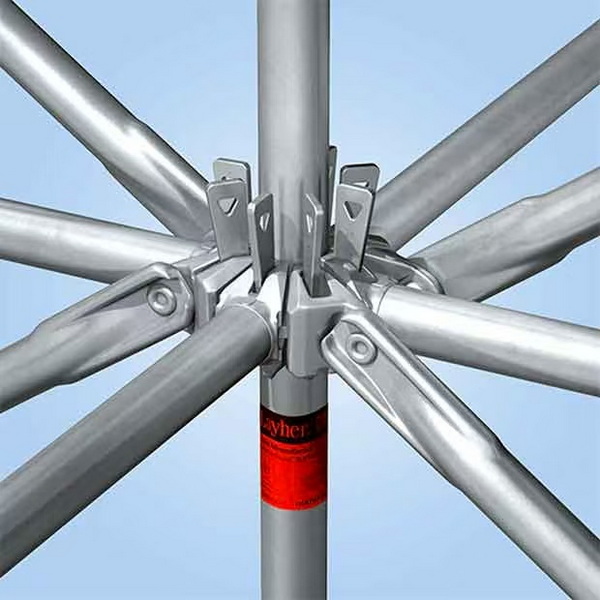

Understanding the Components and Their Impact on Cost

A rosette scaffolding system's cost is deeply intertwined with its constituent parts. A solid grasp of these elements is crucial for effectively evaluating quotes and making well-informed decisions.

Standards (Verticals)

Standards, or uprights, are vital for transmitting loads to the ground. These vertical elements feature welded rosettes, offering connection nodes at regular intervals. The cost of standards varies based on:

- Material Quality: High-tensile steel enhances strength but also increases expenses.

- Length: Longer standards require more material, thus raising the price.

- Rosette Spacing: Shorter intervals between rosettes boost versatility but may also add to the cost.

Ledgers (Horizontals)

Ledgers deliver horizontal support and form the scaffold's working platform. Factors influencing their price include:

- Material and Finish: Galvanized steel offers corrosion resistance, affecting the price.

- Length: Longer ledgers demand more material, elevating the cost.

- Connection Type: The sophistication and ease of use of the connection mechanism can influence price.

Braces (Diagonals)

Braces add lateral stability to the scaffolding structure. Their cost depends on:

- Type of Bracing: Facade or bay braces have varying material needs.

- Length: Longer spans necessitate more material, increasing the cost.

- Adjustability: Adjustable braces offer flexibility, potentially impacting cost.

Platforms and Decks

These elements create the scaffold's working surface. Cost considerations include:

- Material: Steel, aluminum, or wood each have their own price points.

- Load Capacity: Higher load ratings demand more robust materials, thus affecting cost.

- Surface Treatment: Anti-slip coatings or textures add to the price.

Accessories

A range of accessories enhance the functionality and safety of rosette scaffolding systems. These include:

- Base Jacks: Essential for leveling the scaffold on uneven surfaces.

- Toe Boards: Prevent tools and materials from falling.

- Guardrails: Offer fall protection.

- Stair Systems: Safe access between scaffold levels.

- The impact on cost: The more accessories required for the complexity of the job, the higher the overall price[5].

Factors Influencing the Overall Cost of a Rosette Scaffolding System

Beyond the individual components, several external factors can significantly affect the total expense.

Material Quality

The caliber of the steel used directly influences the system's durability and safety. High-grade steel and robust manufacturing processes may lead to a higher upfront investment but deliver long-term savings via extended lifespan and reduced maintenance[2].

Manufacturing Standards and Certifications

Scaffolding systems that adhere to international standards such as OSHA or EN standards typically cost more due to rigorous testing and compliance procedures[6]. However, these certifications assure safety and reliability, potentially lowering liability risks.

Supplier Reputation and Location

Established suppliers with a proven track record may charge a premium for their products. However, they often provide superior customer support and warranties. The supplier's location also affects transportation costs, especially for large projects.

Project Size and Complexity

Larger projects necessitate more scaffolding material, naturally increasing the overall cost. Complex architectural designs that demand specialized configurations and accessories further drive up expenses[2].

Labor Costs for Assembly and Dismantling

The ease of assembly and dismantling is a crucial factor. Rosette scaffolding systems are known for their quick setup, which can reduce labor costs compared to traditional scaffolding methods. The quicker assembly times translate to lower labor expenses[3].

Transportation and Logistics

The cost of transporting the scaffolding materials to the job site is a significant consideration, particularly for projects in remote locations[8]. Efficient logistics planning can help minimize these expenses. The system's lightweight design assists with transportation and handling[8].

Maintenance and Repair Costs

High-quality rosette scaffolding systems require less maintenance. Opting for systems with durable finishes, like hot-dip galvanization, can decrease long-term maintenance expenses[2].

Rental vs. Purchase

Deciding whether to rent or buy a rosette scaffolding system hinges on your specific needs. Renting is often more economical for short-term projects, while purchasing is beneficial for companies with ongoing scaffolding requirements[5].

Estimating the Cost: A Practical Approach

To accurately estimate the cost of a rosette scaffolding system, follow these steps:

1. Define Project Requirements: Determine the scaffold's dimensions, load-bearing needs, and any unique challenges posed by the project[2].

2. Request Multiple Quotes: Contact several reputable suppliers to obtain detailed quotations.

3. Compare Quotes: Evaluate quotes based on material quality, certifications, and included services.

4. Factor in Hidden Costs: Account for transportation, assembly, dismantling, and potential maintenance expenses.

5. Assess Long-Term Value: Consider the system's durability, reusability, and impact on project timelines.

Real-World Cost Examples

While specific costs vary, here are some general estimates:

- Small Construction Project: For a small residential project requiring scaffolding for a few weeks, renting a basic rosette scaffolding system might cost between \$500 to \$1,500[7].

- Medium-Sized Commercial Building: Purchasing scaffolding for a mid-sized commercial building could range from \$10,000 to \$30,000, depending on the system's size and complexity[1].

- Large Industrial Facility: Large-scale industrial projects might require an investment of \$50,000 to \$100,000 or more for a comprehensive rosette scaffolding system.

Cost-Saving Strategies

Several strategies can help mitigate the costs associated with rosette scaffolding systems:

- Plan Carefully: Accurate project planning minimizes the need for alterations and additional components[2].

- Negotiate with Suppliers: Negotiate pricing with suppliers, especially for bulk orders or long-term contracts[1].

- Invest in Training: Properly trained personnel can assemble and dismantle the system efficiently, reducing labor costs[3].

- Maintain the System: Regular maintenance extends the system's lifespan and reduces the need for replacements[2].

Conclusion

The cost of a rosette scaffolding system is a multifaceted equation influenced by numerous factors, from component quality to project complexity. A thorough understanding of these elements enables informed decision-making, ensuring you achieve optimal value, safety, and efficiency.

FAQ

1. What is the typical lifespan of a rosette scaffolding system?

The lifespan of a rosette scaffolding system largely depends on the quality of materials, frequency of use, and maintenance practices. High-quality, galvanized steel systems can last 15-20 years with proper care[2].

2. Is it more cost-effective to rent or buy a rosette scaffolding system?

The decision to rent or buy hinges on project duration and frequency. Renting is generally more cost-effective for short-term, infrequent projects, while purchasing is advantageous for ongoing or long-term scaffolding needs[5].

3. What safety certifications should I look for when purchasing a rosette scaffolding system?

When purchasing a rosette scaffolding system, look for systems that meet or exceed safety standards set by organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute). These certifications ensure the scaffolding has been tested and meets specific safety requirements[6].

4. How does the rosette design contribute to cost savings?

The rosette design, with its multiple connection points, offers exceptional versatility and reduces the need for additional components. This design simplifies assembly, reduces labor costs, and minimizes material waste[2].

5. Can rosette scaffolding systems be adapted for use on uneven terrain?

Yes, rosette scaffolding systems can be adapted for use on uneven terrain by using adjustable base jacks[8]. These jacks compensate for variations in ground level, ensuring the scaffold is level and stable.

Citations:

[1] https://www.made-in-china.com/products-search/hot-china-products/Rosette_Scaffolding.html

[2] https://peakscaffolding.ca/the-benefits-of-ringlock-scaffolding/

[3] https://www.scafom-rux.com/en/scaffolding-blog/5-reasons-to-use-a-ringlock-system-scaffold

[4] https://www.layher.com.au/allround-scaffolding-system/

[5] https://layherna.com/how-choice-of-scaffolding-can-save/

[6] https://www.safesmartaccess.co.nz/5-reasons-for-using-ring-lock-scaffolding/

[7] https://www.alibaba.com/showroom/rosette-scaffolding-system.html

[8] https://rapid-scafform.com/ringlock-scaffolding/