Content Menu

● Introduction to Cuplock Scaffolding

● Components of Cuplock Scaffolding

● Cuplock Scaffolding Price

● Factors Affecting Cost

● Calculating the Cost of Cuplock Scaffolding

>> Example Calculation

>> Additional Costs

● Advantages of Cuplock Scaffolding

● Case Studies

>> Example Project: High-Rise Building

>> Example Project: Bridge Repair

● Conclusion

● FAQ

>> 1. What is the typical cost of cuplock scaffolding per meter?

>> 2. How do I calculate the total cost of cuplock scaffolding for a project?

>> 3. What factors affect the cost of cuplock scaffolding?

>> 4. Is cuplock scaffolding more cost-effective than traditional scaffolding systems?

>> 5. Where can I purchase cuplock scaffolding components?

● Citations:

Cuplock scaffolding is a widely used system in construction projects due to its efficiency, durability, and ease of assembly. It is composed of various components such as standards, ledgers, and braces, which are connected using a unique locking mechanism. Understanding the cost of cuplock scaffolding per meter is crucial for project planning and budgeting. In this article, we will delve into the factors affecting the cost, provide an overview of the pricing, and discuss how to calculate the total cost for a project.

Introduction to Cuplock Scaffolding

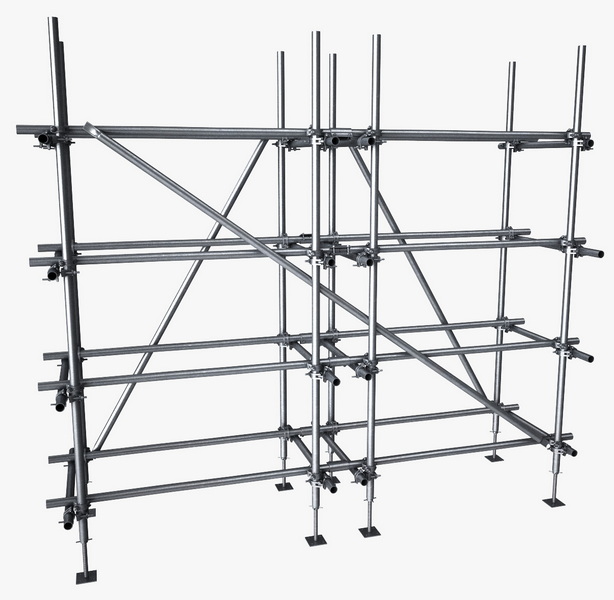

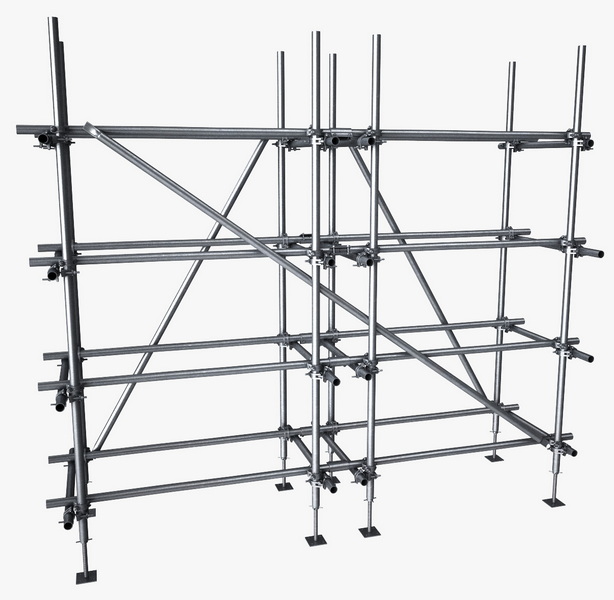

Cuplock scaffolding is a modular system that allows for quick and secure assembly. It uses a "cup" and "blade" mechanism to lock vertical and horizontal components together, making it faster and more efficient than traditional scaffolding systems. The materials used are typically high-strength steel, such as Q355 or S355, with a hot-dip galvanized finish for durability and corrosion resistance.

Components of Cuplock Scaffolding

- Standards: These are the vertical poles that provide the main support for the scaffolding structure. They come in various lengths and are typically made from 48.3mm diameter pipes with a thickness of 3.2mm.

- Ledgers: These are the horizontal beams that connect the standards, providing a framework for the scaffolding boards. They also use 48.3mm diameter pipes with a thickness of 3.2mm.

- Braces: These are diagonal supports that add stability to the scaffolding structure. They use slightly thinner pipes, typically 2.5mm thick.

- Boards: These are the platforms on which workers stand. They are typically made of wood or aluminum and are placed on top of the ledgers.

Cuplock Scaffolding Price

The cost of cuplock scaffolding can vary significantly based on several factors, including location, material quality, and project complexity. Generally, the prices for individual components can range as follows:

- Verticals: $11.00 to $14.00 per piece for heavy-duty verticals, with a minimum order of 500 pieces.

- Ledger Blades: $0.30 to $0.95 per piece, with a minimum order of one piece.

- Complete Systems: Prices can vary widely depending on the specific components and accessories included. For example, a basic cuplock system might cost between $0.50 and $3.50 per piece for certain parts, with a minimum order of 1000 pieces.

Factors Affecting Cost

1. Material Quality: High-quality materials, such as hot-dip galvanized steel, are more expensive but offer better durability and resistance to corrosion.

2. Project Complexity: Projects requiring custom scaffolding designs or complex structures may incur higher costs due to the need for specialized components and labor.

3. Location: Prices can vary significantly based on the location due to differences in labor costs, transportation fees, and local market conditions.

4. Safety Features: Additional safety features, such as guardrails or toe boards, can increase the overall cost of the scaffolding system.

5. Transportation Costs: The cost of transporting scaffolding components to the site can add to the overall expense, especially for remote locations.

Calculating the Cost of Cuplock Scaffolding

To calculate the total cost of cuplock scaffolding for a project, you need to determine the total area that requires scaffolding coverage and multiply it by the cost per square meter. The formula for calculating the area is typically the height of the structure multiplied by its perimeter.

Example Calculation

1. Determine the Total Area:

- Height of the building: 30 meters

- Perimeter of the building: 60 meters

- Total scaffolding area = Height × Perimeter = 30 m × 60 m = 1800 m²

2. Calculate the Cost:

- Assume a base rate of £20 per square meter.

- Total cost = Total area × Rate per m² = 1800 m² × £20/m² = £36,000

Additional Costs

- Material Costs: Estimate the cost of tubes, boards, and fittings. Tubes typically account for about 50% of material costs.

- Labor Costs: Include the cost of assembling and dismantling the scaffolding. Labor costs can vary significantly based on location and the complexity of the structure.

- Safety and Access Costs: Factor in any additional safety measures or access difficulties. This might include the cost of guardrails, toe boards, or specialized equipment for hard-to-reach areas.

Advantages of Cuplock Scaffolding

1. Efficiency: Cuplock scaffolding is known for its quick assembly and disassembly times, which can significantly reduce labor costs.

2. Durability: The use of high-strength steel and galvanized finishes ensures that cuplock scaffolding can withstand harsh weather conditions and heavy use.

3. Flexibility: The modular design allows for easy adaptation to different project requirements, making it suitable for a wide range of construction projects.

4. Safety: The secure locking mechanism and robust structure provide a safe working platform for workers.

Case Studies

Example Project: High-Rise Building

In a recent project for a high-rise building, cuplock scaffolding was chosen due to its ability to support complex structures and provide a safe working environment. The project involved scaffolding the entire facade of a 50-story building, requiring over 10,000 meters of scaffolding.

- Cost Breakdown:

- Material Costs: $150,000

- Labor Costs: $200,000

- Safety and Access Costs: $30,000

- Total Cost: $380,000

Example Project: Bridge Repair

For a bridge repair project, cuplock scaffolding was used to provide access to the underside of the bridge. The project required specialized components to ensure stability over water.

- Cost Breakdown:

- Material Costs: $80,000

- Labor Costs: $120,000

- Safety and Access Costs: $40,000

- Total Cost: $240,000

Conclusion

Cuplock scaffolding offers a reliable and efficient solution for construction projects, but understanding its pricing is crucial for effective budgeting. The cost per meter can vary based on several factors, including material quality, project complexity, and location. By calculating the total area to be covered and considering additional costs, you can accurately estimate the total expense for your project.

FAQ

1. What is the typical cost of cuplock scaffolding per meter?

The cost of cuplock scaffolding per meter can vary significantly based on the components and location. Generally, individual components like verticals or ledger blades are priced rather than the scaffolding as a whole per meter.

2. How do I calculate the total cost of cuplock scaffolding for a project?

To calculate the total cost, determine the total area that needs scaffolding coverage by multiplying the height of the structure by its perimeter. Then, multiply this area by the cost per square meter, considering additional costs for materials, labor, and safety features.

3. What factors affect the cost of cuplock scaffolding?

Factors affecting the cost include material quality, project complexity, location, and additional safety features. High-quality materials and complex projects tend to increase costs.

4. Is cuplock scaffolding more cost-effective than traditional scaffolding systems?

Cuplock scaffolding is often more cost-effective due to its faster assembly and disassembly times, which can reduce labor costs. Additionally, its modular design allows for efficient reuse of components.

5. Where can I purchase cuplock scaffolding components?

Cuplock scaffolding components can be purchased from suppliers like Total Contec or through online platforms like Alibaba. It's important to ensure that the components meet quality and safety standards.

Citations:

[1] https://rapid-scafform.com/how-to-calculate-the-rate-of-scaffolding/

[2] https://www.youtube.com/watch?v=wBKilb9ALEY

[3] https://rapid-scafform.com/cuplock-scaffold/

[4] https://www.alibaba.com/showroom/cuplock-scaffolding-price-in-india.html

[5] https://dir.indiamart.com/impcat/cuplock-scaffolding.html

[6] https://www.youtube.com/watch?v=fnJw0xLZE5s

[7] https://www.wm-scaffold.com/cup-lock-scaffold.html

[8] https://www.made-in-china.com/products-search/hot-china-products/Cuplock_Scaffold_Price.html

[9] https://www.alibaba.com/showroom/cuplock-scaffolding-prices.html

[10] https://www.youtube.com/watch?v=l7SdKkdbeU4

[11] https://jumplyscaffolding.com/what-is-cuplock-scaffolding/

[12] https://scaffolding-solutions.com.cy/wp-content/uploads/2022/06/user_manual_cuplok_10-2006.pdf