Content Menu

● Introduction to Aluminum Walk Planks

● Advantages of Aluminum Walk Planks

● Strength of Aluminum Walk Planks

>> Mechanical Properties

>> Design Features Enhancing Strength

● Durability of Aluminum Walk Planks

>> Resistance to Environmental Damage

>> Maintenance Requirements

>> Protective Coatings

● Applications of Aluminum Walk Planks

>> Construction Sites

>> Industrial Settings

>> Event Management

● Cost Considerations

● Conclusion

● FAQ

>> 1. What makes aluminum walk planks strong?

>> 2. How much weight can an aluminum walk plank support?

>> 3. Are aluminum walk planks suitable for outdoor use?

>> 4. What maintenance do aluminum walk planks require?

>> 5. How do protective coatings enhance the durability of aluminum walk planks?

● Citations:

Aluminum walk planks are essential components in construction and scaffolding, providing safe and stable platforms for workers at various heights. Their strength and durability make them a preferred choice over traditional materials such as wood and steel. This article explores the strength, durability, applications, and maintenance of aluminum walk planks, highlighting their benefits in the construction industry.

Introduction to Aluminum Walk Planks

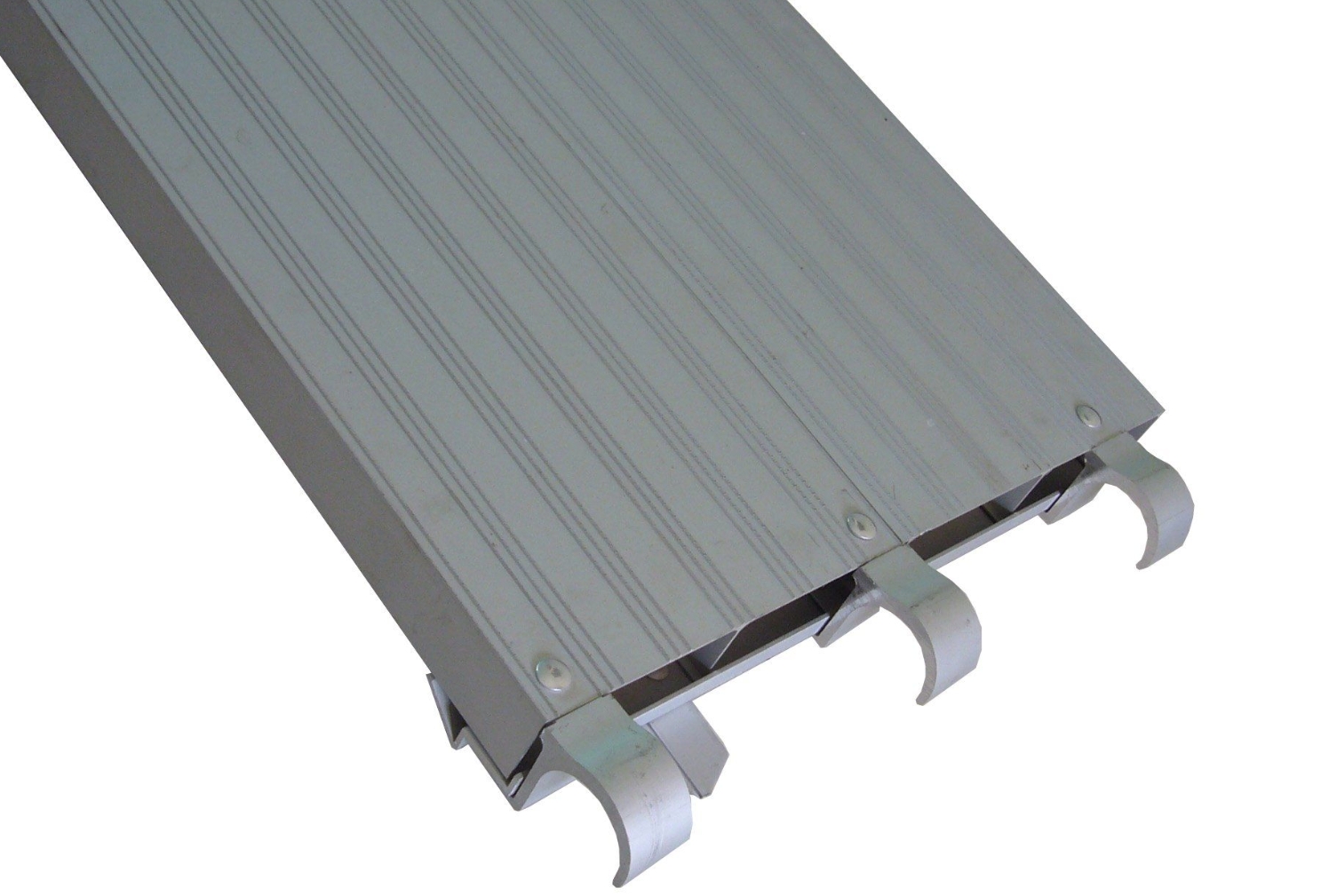

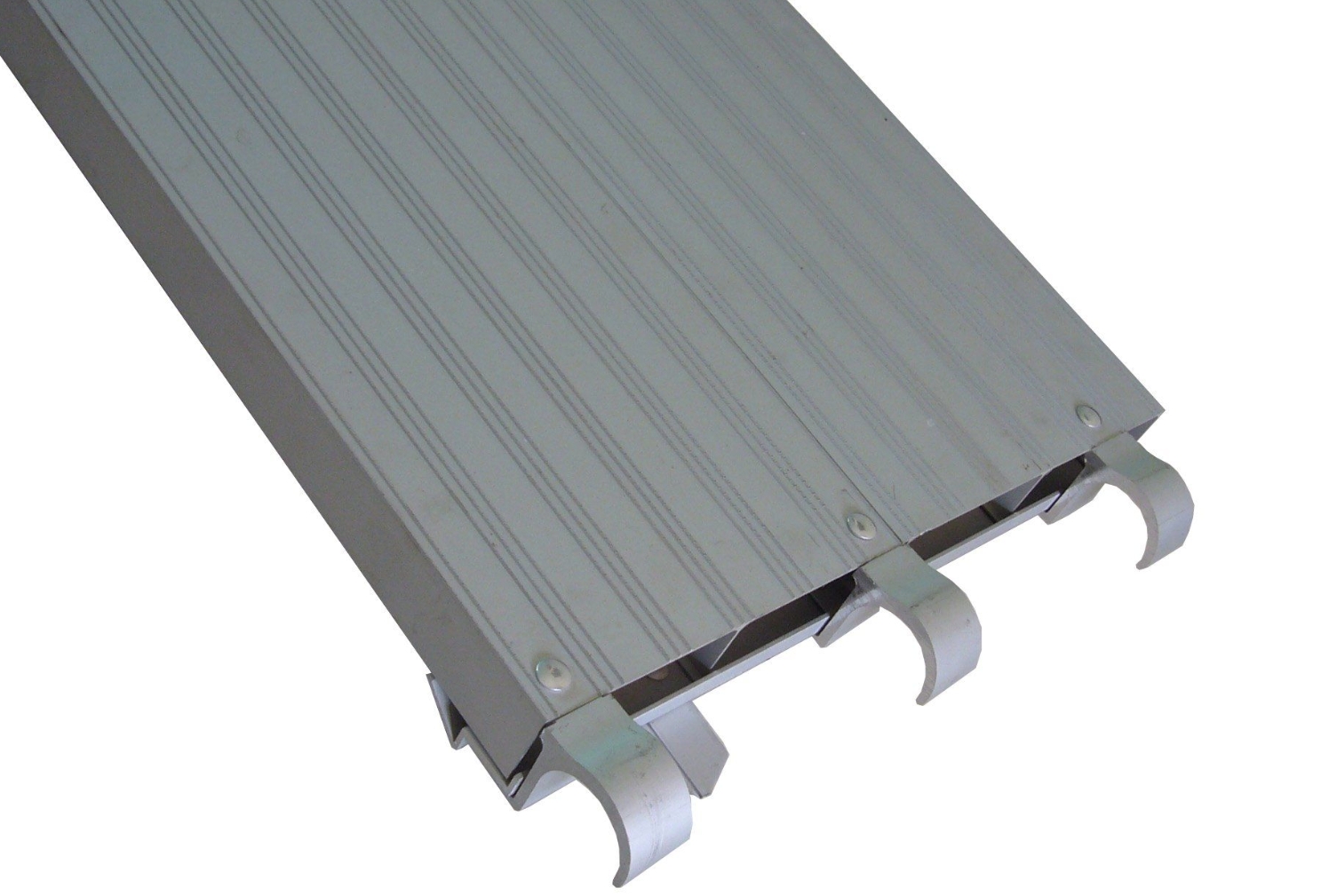

Aluminum walk planks are lightweight yet robust boards made from high-quality aluminum alloys. These planks are designed to support heavy loads while providing a stable surface for workers. They are commonly used in scaffolding systems, allowing for safe access to elevated areas during construction, maintenance, and repair work.

Advantages of Aluminum Walk Planks

- Lightweight: Aluminum walk planks are significantly lighter than wood or steel planks, making them easier to transport and handle on job sites.

- High Strength: Despite their lightweight nature, aluminum planks can support substantial loads due to their inherent strength.

- Corrosion Resistance: Aluminum is naturally resistant to rust and corrosion, which is crucial for outdoor applications exposed to the elements.

- Low Maintenance: Unlike wood, which may require regular sealing or treatment, aluminum walk planks need minimal maintenance, reducing long-term costs.

Strength of Aluminum Walk Planks

The strength of aluminum walk planks is primarily due to the properties of the aluminum alloy used in their construction. Commonly used alloys include 6061-T6 and 6063-T6, known for their excellent mechanical properties.

Mechanical Properties

- Tensile Strength: Aluminum alloys exhibit high tensile strength, allowing them to withstand significant pulling forces without breaking.

- Impact Resistance: Aluminum walk planks can absorb impacts without deforming or cracking, making them suitable for high-traffic work environments.

- Load Capacity: Depending on their design and dimensions, aluminum walk planks can typically support loads ranging from 500 to 1,100 pounds (227 to 500 kg).

Design Features Enhancing Strength

Modern aluminum walk planks are designed with several features that enhance their strength:

- Ribbed Surface: Many aluminum planks come with a ribbed surface that provides additional grip for workers, reducing the risk of slips and falls.

- Extruded Profiles: The use of extruded profiles ensures uniform thickness and structural integrity throughout the plank.

Durability of Aluminum Walk Planks

Aluminum walk planks are renowned for their durability. They can withstand various environmental conditions without degrading over time. Factors contributing to their longevity include:

Resistance to Environmental Damage

- Weather Resistance: Aluminum does not rust or corrode like steel or wood when exposed to moisture or harsh weather conditions. This makes it ideal for outdoor applications where exposure to rain or humidity is common.

- UV Resistance: Many aluminum walk planks come with protective coatings that enhance their resistance to UV rays, preventing fading and degradation from sunlight exposure.

Maintenance Requirements

While aluminum walk planks require minimal maintenance, regular upkeep is essential to ensure their longevity:

- Cleaning: Regularly clean the surface of the planks using mild detergents and water to remove dirt and debris that may accumulate over time.

- Inspection: Conduct periodic inspections for signs of wear or damage. Look for dents, scratches, or any bending that could compromise structural integrity.

Protective Coatings

Applying protective coatings such as powder coating or anodizing can significantly enhance the durability of aluminum walk planks by providing additional resistance against corrosion and wear.

Applications of Aluminum Walk Planks

Aluminum walk planks are versatile and can be used across various industries and applications:

Construction Sites

In construction settings, aluminum walk planks provide safe access platforms for workers performing tasks at height. They can be used in:

- Scaffolding Systems: Used as platforms within scaffolding structures to support workers and materials safely.

- Staging Areas: Ideal for creating temporary staging areas during events or construction projects.

Industrial Settings

Aluminum walk planks are also utilized in industrial environments where heavy equipment and materials are handled:

- Maintenance Platforms: Provide stable surfaces for maintenance personnel working on machinery or equipment at elevated heights.

- Access Walkways: Used as access pathways between different sections of a facility or construction site.

Event Management

In event management, aluminum walk planks are often employed for staging platforms or temporary structures due to their lightweight nature and ease of setup.

Cost Considerations

While the initial cost of aluminum walk planks may be higher than traditional wood or steel options, their long-term benefits often outweigh this expense:

- Longevity: The durability and resistance to environmental damage mean that aluminum walk planks typically last longer than wood or steel alternatives.

- Reduced Maintenance Costs: Minimal maintenance requirements translate into lower costs over time compared to other materials that may require regular treatments or replacements.

Conclusion

Aluminum walk planks offer exceptional strength and durability, making them an ideal choice for various construction applications. Their lightweight nature combined with high load capacity ensures safety and efficiency on job sites. By understanding the properties, benefits, and maintenance requirements of aluminum walk planks, construction professionals can make informed decisions that enhance safety and productivity in their projects.

FAQ

1. What makes aluminum walk planks strong?

Aluminum walk planks are made from high-strength alloys like 6061-T6, which provide excellent tensile strength and impact resistance while being lightweight.

2. How much weight can an aluminum walk plank support?

Depending on its design and dimensions, an aluminum walk plank can typically support loads ranging from 500 to 1,100 pounds (227 to 500 kg).

3. Are aluminum walk planks suitable for outdoor use?

Yes, aluminum walk planks are highly suitable for outdoor use due to their resistance to corrosion and environmental damage from moisture and UV exposure.

4. What maintenance do aluminum walk planks require?

Regular cleaning with mild detergents and periodic inspections for wear or damage are essential for maintaining the longevity of aluminum walk planks.

5. How do protective coatings enhance the durability of aluminum walk planks?

Protective coatings like powder coating provide additional resistance against corrosion and wear, extending the lifespan of aluminum walk planks in harsh environments.

Citations:

[1] https://www.tytruss.com/newsclass_2/Durability-Longevity-Scaffolding-Aluminum-Planks.shtml

[2] https://www.tp-scaffold.com/what-are-aluminum-scaffolding-planks.html

[3] https://aaitscaffold.com/blog/the-many-advantages-of-aluminium-planks-in-construction/

[4] https://apacscaffold.com/aluminum-walk-boards/

[5] https://jumplyscaffolding.com/aluminum-plank/

[6] https://utmscaffold.en.made-in-china.com/product/KJardLDAscUi/China-Construction-All-Aluminium-Plank-Catwalk-Board-Aluminium-Scaffold.html

[7] https://pcp-corp.com/en/products/product-categories/planks/

[8] https://www.capral.com.au/extrusion-plate-sheet/extrusion/scaffolding/