Content Menu

● What Are Scaffolding Swivel Clamps and Fixed Clamps?

>> Scaffolding Swivel Clamp

>> Fixed Clamp (Right Angle Clamp)

● Load Capacity and Strength Comparison

>> Working Load Capacity of Fixed Clamps

>> Working Load Capacity of Scaffolding Swivel Clamps

>> Summary Table: Load Capacities

● Structural Strength and Stability

>> Fixed Clamps Provide Maximum Rigidity

>> Swivel Clamps Offer Flexibility with Slightly Reduced Rigidity

● Material and Manufacturing Considerations

● Practical Applications and Recommendations

>> When to Use Fixed Clamps

>> When to Use Scaffolding Swivel Clamps

>> Combining Both Clamp Types

● Installation and Safety Best Practices

>> Proper Installation

>> Regular Inspection and Maintenance

>> Safety Tips

● Conclusion

● FAQ

>> 1. What is the main difference between scaffolding swivel clamps and fixed clamps?

>> 2. Are scaffolding swivel clamps as strong as fixed clamps?

>> 3. Can scaffolding swivel clamps be used in place of fixed clamps?

>> 4. How do I ensure the clamps are securely fastened?

>> 5. Are swivel clamps more expensive than fixed clamps?

● Citations:

In scaffolding construction, clamps are fundamental components that hold scaffold tubes together, ensuring the structure's stability and safety. Two of the most common types of scaffolding clamps are scaffolding swivel clamps and fixed clamps (also known as right-angle clamps or double couplers). Understanding the strength differences, applications, and limitations of these clamps is essential for scaffold designers, erectors, and safety inspectors.

What Are Scaffolding Swivel Clamps and Fixed Clamps?

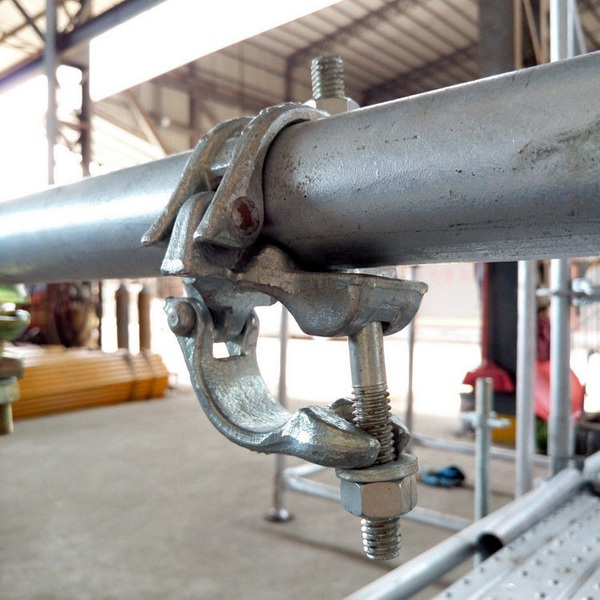

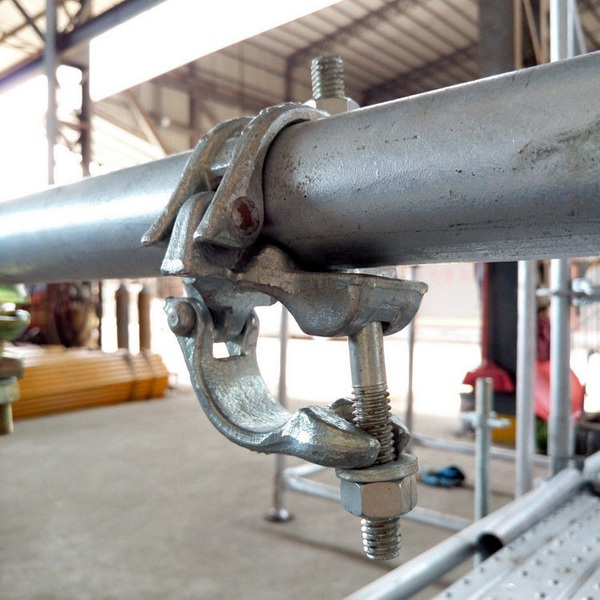

Scaffolding Swivel Clamp

A scaffolding swivel clamp is a coupler that connects two scaffold tubes at any angle, allowing 360 degrees of rotation between the tubes. This flexibility makes swivel clamps ideal for bracing, diagonal supports, and complex scaffold geometries where tubes do not meet at right angles.

- Made from drop-forged steel or pressed steel.

- Typically hot-dip galvanized or zinc-plated for corrosion resistance.

- Designed to accommodate scaffold tubes of 48.3 mm diameter (most common).

- Allows angular adjustment during assembly for flexible scaffold design.

Fixed Clamp (Right Angle Clamp)

A fixed clamp, also called a right-angle or double coupler, connects two scaffold tubes rigidly at a 90-degree angle. It is the backbone of scaffold framing, used to join vertical standards to horizontal ledgers or transoms, providing a stable and strong connection.

- Also made from forged or pressed steel with corrosion-resistant finish.

- Designed for a fixed, non-adjustable 90-degree connection.

- Provides a rigid joint essential for load-bearing scaffold components.

Load Capacity and Strength Comparison

Working Load Capacity of Fixed Clamps

- Fixed clamps can support heavy loads, typically exceeding 30 kN (kilonewtons), meeting or surpassing EN74 Class B standards.

- The rigid 90-degree connection provides excellent resistance to bending, shear, and torsion forces.

- Used primarily in the main structural framework, fixed clamps ensure scaffold stability under vertical and lateral loads.

Working Load Capacity of Scaffolding Swivel Clamps

- Swivel clamps generally support loads of 20 kN or more (EN74 Class B) and 14 kN (EN74 Class A), depending on quality and manufacturer.

- Their ability to rotate allows connection at any angle but results in slightly lower maximum load capacity compared to fixed clamps.

- Swivel clamps are crucial for diagonal bracing and irregular scaffold geometries but are not typically used as primary load-bearing joints.

Summary Table: Load Capacities

| Clamp Type | Typical Load Capacity (EN74 Class B) | Typical Load Capacity (EN74 Class A) | Connection Angle | Primary Use |

| Fixed Clamp (Right Angle) | > 30 kN | N/A | Fixed 90 degrees | Main structural joints |

| Scaffolding Swivel Clamp | > 20 kN | ~14 kN | Any angle (0-360°) | Bracing, diagonal supports, flexible connections |

Structural Strength and Stability

Fixed Clamps Provide Maximum Rigidity

By locking scaffold tubes at a right angle, fixed clamps create a rigid frame that resists deformation under heavy loads. This rigidity is crucial for:

- Maintaining scaffold shape and alignment.

- Supporting vertical loads from workers, materials, and equipment.

- Resisting lateral forces such as wind or accidental impact.

Fixed clamps are often the preferred choice for the primary scaffold framework because they ensure that the scaffold remains square and stable. The rigid connection minimizes any movement between scaffold tubes, which is vital for worker safety and structural integrity.

Swivel Clamps Offer Flexibility with Slightly Reduced Rigidity

The swivel mechanism allows tubes to be connected at any angle, which is essential for:

- Attaching diagonal braces that stabilize scaffolds against swaying.

- Constructing scaffolds on uneven or sloping ground.

- Creating curved or irregular scaffold shapes.

However, this flexibility means the joint can rotate slightly under load, potentially reducing overall stiffness compared to fixed clamps. While swivel clamps provide the necessary adaptability for complex scaffold designs, they should not be relied upon for the main load-bearing joints. The slight movement inherent in swivel clamps can lead to increased wear over time if used improperly.

Material and Manufacturing Considerations

The strength of both scaffolding swivel clamps and fixed clamps depends heavily on the materials used and the manufacturing process.

- Material Quality: High-grade forged steel is preferred for both clamp types due to its superior strength and durability. Lower-grade materials may fail under load, risking scaffold collapse.

- Corrosion Resistance: Hot-dip galvanizing or zinc plating is standard to protect clamps from rust and corrosion, especially in outdoor or marine environments.

- Manufacturing Precision: Clamps must be manufactured to tight tolerances to ensure proper fit and secure fastening. Poorly made clamps can loosen or deform under load.

Manufacturers often provide load ratings and certification details for their scaffolding clamps. It is critical to use clamps that meet recognized standards such as EN74 in Europe or OSHA requirements in the US.

Practical Applications and Recommendations

When to Use Fixed Clamps

- For main scaffold frames where maximum strength and rigidity are required.

- Connecting vertical standards to horizontal ledgers and transoms.

- Situations demanding high load-bearing capacity and minimal joint movement.

- When erecting scaffolds that will support heavy equipment or materials.

When to Use Scaffolding Swivel Clamps

- For diagonal bracing to enhance scaffold stability.

- On irregular or curved scaffolds where tube angles vary.

- Temporary or adjustable connections requiring angular flexibility.

- When scaffolding must adapt to uneven terrain or complex architectural features.

Combining Both Clamp Types

Most scaffolding systems use a combination of fixed and swivel clamps. Fixed clamps form the scaffold's backbone, while swivel clamps provide the necessary flexibility for bracing and complex geometries. This combination ensures that the scaffold is both strong and adaptable.

Installation and Safety Best Practices

Proper Installation

- Always use the correct clamp type for the application.

- Tighten clamp bolts to the manufacturer's recommended torque, usually around 54 Nm (40 ft-lbs).

- Use calibrated torque wrenches to ensure consistent tightening.

- Avoid overtightening clamps, which can damage tubes or the clamp itself.

Regular Inspection and Maintenance

- Inspect clamps before each use for cracks, corrosion, or deformation.

- Replace any clamps showing signs of wear or damage immediately.

- Check clamp tightness regularly during scaffold use.

- Store clamps in dry conditions to minimize corrosion.

Safety Tips

- Never substitute clamps with lower-rated alternatives.

- Follow scaffold design specifications and load limits.

- Train workers on proper clamp installation and scaffold assembly.

- Use personal protective equipment (PPE) when erecting or dismantling scaffolds.

Conclusion

Both scaffolding swivel clamps and fixed clamps are indispensable in scaffold construction, each serving distinct roles. Fixed clamps provide superior strength and rigidity for the scaffold's main framework, supporting heavy loads and ensuring structural stability. Scaffolding swivel clamps offer essential flexibility, enabling connections at any angle and facilitating diagonal bracing and complex scaffold designs.

While swivel clamps have a slightly lower load capacity compared to fixed clamps, their versatility makes them crucial for safe and adaptable scaffold structures. Using both clamp types appropriately, following safety standards, and ensuring proper installation guarantees a safe, stable, and efficient scaffolding system.

FAQ

1. What is the main difference between scaffolding swivel clamps and fixed clamps?

Answer: Fixed clamps connect scaffold tubes rigidly at a 90-degree angle, providing maximum strength and stability, while scaffolding swivel clamps allow connection at any angle with 360-degree rotation, offering flexibility but slightly less rigidity.

2. Are scaffolding swivel clamps as strong as fixed clamps?

Answer: No, fixed clamps generally have a higher load capacity (over 30 kN) compared to swivel clamps (around 20 kN), making fixed clamps stronger for load-bearing joints.

3. Can scaffolding swivel clamps be used in place of fixed clamps?

Answer: Swivel clamps should not replace fixed clamps in primary structural connections because they allow movement. They are best used for bracing and non-load-bearing or flexible joints.

4. How do I ensure the clamps are securely fastened?

Answer: Use a scaffold spanner or torque wrench to tighten clamp bolts to the recommended torque, usually about 54 Nm. Regularly inspect clamps for looseness or damage during scaffold use.

5. Are swivel clamps more expensive than fixed clamps?

Answer: Generally, swivel clamps can be slightly more expensive due to their more complex design and functionality, but prices vary by manufacturer and quality.

Citations:

[1] https://rlsdhamal.com/scaffolding-couplers-working-load-capacity/

[2] https://www.wm-scaffold.com/scaffolding-coupler.html

[3] https://www.gz-supplies.com/compare/807/808/809/810

[4] https://gezuimpex.shop/products/swivel-coupler-clamp-for-coupling-s6

[5] https://www.tp-scaffold.com/amp/how-does-a-scaffolding-right-angle-coupler-compare-to-other-couplers.html

[6] https://www.gd-scaffold.com/news/what-is-the-difference-between-swivel-scaffolding-clamps-and-right-angle-scaffolding-clamps.html

[7] https://durainternational.com.my/NewsDetail/a-brief-overview-of-double-coupler-and-its-capacity/36a90a21-114f-4528-ac5a-f2586b255b78?pageSize=8&pageSize=8

[8] https://www.tp-scaffold.com/what-is-fixed-clamp-scaffolding-and-how-does-it-work.html