Content Menu

● Introduction to Aluminum Scaffolding Planks

● Key Features of Aluminum Scaffolding Planks

● Benefits of Using Aluminum Scaffolding Planks

● Popular Models of Aluminum Scaffolding Planks

>> Bil-Jax Scaffold Plank

>> Werner Aluminum Scaffold Plank

● Choosing the Right Aluminum Scaffolding Plank

● Comparison Table

● Advanced Features to Consider

● Maintenance and Storage

● Tips for Extending Lifespan

● Safety Precautions

● Conclusion

● FAQ

>> 1. What are the primary uses of aluminum scaffolding planks in construction?

>> 2. How strong are aluminum scaffolding planks?

>> 3. What factors should I consider when choosing an aluminum scaffolding plank?

>> 4. Can aluminum scaffolding planks be used outdoors?

>> 5. How do I maintain my aluminum scaffolding plank?

● Citations:

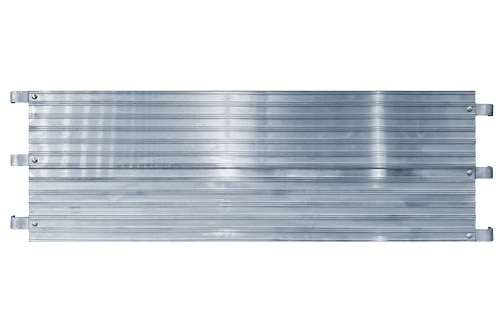

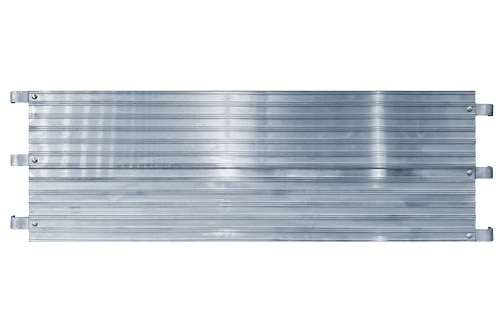

Aluminum scaffolding planks are widely used in construction due to their strength, durability, and lightweight nature. These planks are designed to provide a stable platform for workers at heights, ensuring safety and efficiency in various construction projects. In this article, we will explore the strength and benefits of aluminum scaffolding planks for construction.

Introduction to Aluminum Scaffolding Planks

Aluminum scaffolding planks are made from high-strength 6061-T6 aluminum alloy, known for its excellent corrosion resistance and strength-to-weight ratio[1][4]. They are commonly used with scaffolding systems to provide a stable working platform for tasks such as painting, drywall installation, and window repairs. These planks are particularly useful in construction and maintenance projects due to their versatility and safety features.

Key Features of Aluminum Scaffolding Planks

1. Material: Constructed from 6061-T6 aluminum alloy, which offers high strength and corrosion resistance[1][4].

2. Lightweight: Significantly lighter than wood and steel planks, making them easier to handle and transport[1][4].

3. Durability: Designed to withstand harsh conditions, including moisture and chemicals, without deteriorating[1][4].

4. Load Capacity: Varies depending on the model, with common capacities ranging from 250 lbs to over 9,000 lbs for specialized models[1][2].

Benefits of Using Aluminum Scaffolding Planks

1. Safety: Exceeds all OSHA regulations, ensuring a safe working environment[3][6].

2. Durability: Long-lasting and resistant to corrosion, reducing the need for frequent replacements[1][4].

3. Versatility: Available in various lengths and widths to fit different scaffolding systems[1][3].

4. Cost-Effective: Reduces labor costs due to ease of setup and transport[6].

Popular Models of Aluminum Scaffolding Planks

Bil-Jax Scaffold Plank

The Bil-Jax Scaffold Plank is a popular choice among professionals. It features a load capacity of 500 lbs and is made from durable aluminum[1].

Product Specifications:

- Load Capacity: 500 lbs

- Length: 7 ft

- Material: Aluminum

Werner Aluminum Scaffold Plank

The Werner Aluminum Scaffold Plank is another highly regarded option. It has a load capacity of 250 lbs and is known for its twist-proof design and slip-resistant decking[3].

Product Specifications:

- Load Capacity: 250 lbs

- Length: 7 ft

- Material: Aluminum

Choosing the Right Aluminum Scaffolding Plank

When selecting an aluminum scaffolding plank, consider the following factors:

1. Project Requirements: Determine the length and load capacity needed for your tasks.

2. Compatibility: Ensure the plank is compatible with your existing scaffolding systems.

3. Safety Features: Look for anti-slip surfaces and sturdy construction.

4. Budget: Compare prices and consider the long-term cost savings.

Comparison Table

| Model | Load Capacity | Length | Material |

| Bil-Jax | 500 lbs | 7 ft | Aluminum |

| Werner | 250 lbs | 7 ft | Aluminum |

Advanced Features to Consider

Some advanced models of aluminum scaffolding planks come with additional features that enhance their usability and safety:

1. Replaceable Hooks: Allow for secure attachment to scaffolding frames[2].

2. Locking Mechanism: Ensures planks stay held fast on the scaffolding frame[2].

3. Grooves for Water Removal: Provide good traction and prevent slipping[2].

Maintenance and Storage

To ensure the longevity of your aluminum scaffolding plank:

1. Regular Inspection: Check for any damage or wear.

2. Cleaning: Regularly clean the plank to prevent corrosion.

3. Proper Storage: Store the plank in a dry place when not in use.

Tips for Extending Lifespan

- Avoid Overloading: Never exceed the recommended load capacity.

- Use Protective Covers: Use protective covers to shield the plank from harsh weather conditions.

- Follow Manufacturer Instructions: Always follow the manufacturer's guidelines for use and maintenance.

Safety Precautions

Safety should always be the top priority when using aluminum scaffolding planks:

1. Secure Attachment: Ensure the plank is securely attached to the scaffolding.

2. Three Points of Contact: Maintain three points of contact when climbing or working on the plank.

3. Weight Distribution: Ensure even weight distribution to prevent tipping.

Conclusion

Aluminum scaffolding planks are strong and reliable tools for construction projects, offering safety, durability, and efficiency. When choosing the best aluminum scaffolding plank, consider factors such as project requirements, compatibility, safety features, and budget. Both Bil-Jax and Werner offer high-quality options that cater to different needs and preferences.

FAQ

1. What are the primary uses of aluminum scaffolding planks in construction?

Aluminum scaffolding planks are primarily used for tasks such as painting, drywall installation, plastering, and window repairs. They provide a stable platform when used with scaffolding systems.

2. How strong are aluminum scaffolding planks?

Aluminum scaffolding planks are made from high-strength 6061-T6 aluminum alloy, offering excellent strength and corrosion resistance. Their load capacity varies depending on the model, with common capacities ranging from 250 lbs to over 9,000 lbs for specialized models[1][4].

3. What factors should I consider when choosing an aluminum scaffolding plank?

Consider the length and load capacity needed for your projects, compatibility with your existing scaffolding systems, and the presence of safety features like anti-slip surfaces.

4. Can aluminum scaffolding planks be used outdoors?

Yes, aluminum scaffolding planks are suitable for both indoor and outdoor use due to their weather-resistant finishes and corrosion resistance[1][4].

5. How do I maintain my aluminum scaffolding plank?

Regularly inspect the plank for damage, clean it to prevent corrosion, and store it properly when not in use to extend its lifespan.

Citations:

[1] https://www.tp-scaffold.com/what-are-aluminum-scaffolding-planks.html

[2] https://aaitscaffold.com/products/scaffolding-planks/aluminum-plank/

[3] https://www.associated-scaffolding.com/sales/werner-nestable-aluminum-planks

[4] https://jumplyscaffolding.com/aluminum-plank/

[5] https://biljax.com/scaffold-plank-load-capacity

[6] https://aaitscaffold.com/scaffold-plank/why-aluminum-scaffold-planks-are-an-ideal-choice-for-scaffolding-system/

[7] https://utmscaffold.en.made-in-china.com/product/FmPYcwTxaLrX/China-High-Strength-Standard-Construction-Aluminum-Scaffold-Plank.html

[8] https://www.scaffoldssupply.com/Aluminum-Plank-s/184.htm