Content Menu

● Key Components of Cuplock Scaffolding

● Factors Affecting Cuplock Scaffolding Calculations

● Step-by-Step Calculation Process

>> Step 1: Measure the Structure

>> Step 2: Define Bay Dimensions

>> Step 3: Calculate Standards

>> Step 4: Calculate Ledgers

>> Step 5: Add Decks/Planks

● Practical Example

● Common Mistakes in Calculations

● Safety Considerations

● Regulations and Standards

● Case Studies

>> Example 1: Bridge Construction

>> Example 2: High-Rise Building

● Conclusion

● FAQ

>> 1. How do I calculate the number of standards needed?

>> 2. What factors affect the calculation of Cuplock scaffolding?

>> 3. How do I ensure safety when using Cuplock scaffolding?

>> 4. Can Cuplock scaffolding be used for curved structures?

>> 5. What are common mistakes in Cuplock scaffolding calculations?

● Citations:

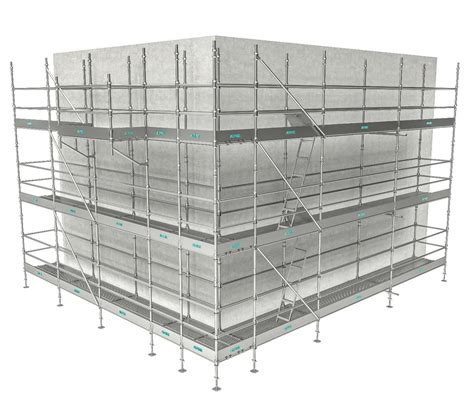

Cuplock scaffolding is a modular system widely used in construction projects for its efficiency, safety, and adaptability. Proper calculation of Cuplock scaffolding materials is essential to ensure structural stability, cost-effectiveness, and compliance with safety standards. This article provides a detailed guide on how to calculate Cuplock scaffolding, including step-by-step instructions, factors to consider, and practical examples.

Key Components of Cuplock Scaffolding

Before diving into calculations, it's important to understand the main components of Cuplock scaffolding:

1. Standards (Verticals):

- These are vertical posts with cup joints at regular intervals.

- They provide the primary load-bearing structure.

2. Ledgers (Horizontals):

- Horizontal bars that connect the standards.

- They stabilize the structure and support working platforms.

3. Base Jacks:

- Adjustable base plates that ensure the scaffold is level on uneven ground.

4. Diagonal Braces:

- Provide additional stability by connecting standards diagonally.

5. Decks/Planks:

- Platforms for workers to stand on or store materials.

6. Guardrails:

- Safety barriers to prevent falls.

7. Toe Boards:

- Installed at platform edges to prevent tools or materials from falling.

Factors Affecting Cuplock Scaffolding Calculations

Calculating Cuplock scaffolding requires consideration of several factors:

1. Wall Dimensions:

- Measure the length and height of the wall or structure requiring scaffolding.

- Calculate the total area to determine the number of bays needed.

2. Bay Dimensions:

- Standard bay sizes include 2m (length) × 0.6m (width) × 2m (height).

- Adjust bay dimensions based on project requirements.

3. Number of Working Levels:

- Determine how many levels (or decks) are required for the project.

- More levels require additional ledgers, standards, and planks.

4. Load Requirements:

- Assess the weight the scaffold needs to support.

- Heavy-duty applications may require reinforced components.

5. Safety Standards:

- Ensure compliance with local regulations such as OSHA or EN 12810.

- Include guardrails, toe boards, and proper anchoring systems.

Step-by-Step Calculation Process

Step 1: Measure the Structure

- Determine the height, length, and width of the structure.

- Example: A building facade measuring 10m high × 20m long requires scaffolding.

Step 2: Define Bay Dimensions

- Choose standard bay dimensions (e.g., 2m × 0.6m × 2m).

- Calculate how many bays fit along the length and height.

- Example: For a 20m length and 10m height with a bay size of 2m × 2m:

Number of bays along length=Length/Bay Length=20/2=10

Number of bays along height=Height/Bay Height=10/2=5

Step 3: Calculate Standards

- Each vertical standard supports one corner of a bay.

- Total standards required:

(Bays along length+1)×(Bays along height+1)

- Example: For a grid of 10×510×5 bays:

(10+1)×(5+1)=66standards

Step 4: Calculate Ledgers

- Horizontal ledgers are required for each level in both directions.

- Total ledgers required horizontally for one level:

(Bays along length)×(Bays along height+1)

- Multiply by the number of levels for total ledgers.

Step 5: Add Decks/Planks

- Each bay requires planks to form a working platform.

- Total planks required per level:

(Bays along length)×(Bays along width)

- Multiply by the number of levels for total planks.

Practical Example

Let's calculate Cuplock scaffolding for a building facade measuring 12m high and 24 m24m long:

1. Bay Dimensions: 2m (length) × 0.6 m0.6m (width) × 2 m2m (height).

2. Number of Bays Along Length: 24/2=1224/2=12.

3. Number of Bays Along Height: 12/2=6..

4. Standards Required:

(12 + 1)/times (6 + 1) = 91

5. Ledgers Required Per Level:

Horizontal direction: 12/times (6 + 1) = 84.

6. Planks Per Level:

12/times (Width Divisions) = X.

Common Mistakes in Calculations

1. Ignoring Load Requirements:

Overlooking weight limits can compromise safety.

2. Incorrect Bay Dimensions:

Using non-standard sizes can lead to material shortages or excess.

3. Omitting Safety Features:

Always include guardrails and toe boards in calculations.

4. Inaccurate Measurements:

Double-check all dimensions before ordering materials.

Safety Considerations

Safety is paramount when using Cuplock scaffolding. Here are some key considerations:

1. Regular Inspections: Regularly inspect scaffolding for damage or wear.

2. Proper Training: Ensure workers are trained in assembly and disassembly procedures.

3. Load Limits: Never exceed the recommended load capacity.

4. Weather Conditions: Secure scaffolding against wind and rain.

Regulations and Standards

Cuplock scaffolding must comply with various safety standards and regulations, such as OSHA guidelines in the U.S. or EN 12811 in Europe. Ensuring compliance is crucial for maintaining a safe working environment.

Case Studies

Example 1: Bridge Construction

Cuplock scaffolding was used in a major bridge project to support formwork during concrete pouring. Its high load-bearing capacity and stability ensured the success of the project.

Example 2: High-Rise Building

In a high-rise construction project, Cuplock scaffolding provided a flexible and safe platform for workers to perform exterior finishing tasks efficiently.

Conclusion

Accurate calculation of Cuplock scaffolding is crucial for ensuring safety, efficiency, and cost-effectiveness in construction projects. By understanding key components, considering critical factors like load requirements and bay dimensions, and following a systematic calculation process, you can optimize your scaffolding setup for any project size or complexity.

FAQ

1. How do I calculate the number of standards needed?

Standards are calculated based on bay layout using this formula:

(Bays Along Length+1)×(Height divisions+1)

2. What factors affect the calculation of Cuplock scaffolding?

Key factors include wall dimensions, bay dimensions, number of working levels, load requirements, and safety standards.

3. How do I ensure safety when using Cuplock scaffolding?

Ensure regular inspections, provide proper training, adhere to load limits, and secure scaffolding against weather conditions.

4. Can Cuplock scaffolding be used for curved structures?

Yes, its modular design allows it to adapt to curved or irregular architectural shapes.

5. What are common mistakes in Cuplock scaffolding calculations?

Common mistakes include ignoring load requirements, using incorrect bay dimensions, omitting safety features, and making inaccurate measurements.

Citations:

[1] https://www.wm-scaffold.com/how-to-calculate-scaffolding/

[2] https://www.youtube.com/watch?v=49X4A66UCbk

[3] https://www.wm-scaffold.com/cup-lock-scaffold.html

[4] https://www.scafom-rux.com/en/scaffolding-blog/beginner-s-guide-to-scaffolding-types-the-cuplock-modular-scaffold

[5] https://www.academia.edu/96263680/Design_Calculations_of_Shuttering_and_Scaffolding_Cuplock_System

[6] https://www.youtube.com/watch?v=4zyqzqQEhRA

[7] https://assets.website-files.com/66f42abc97ec5a674ec026bc/66fa2698689716374a110aee_36019422232.pdf

[8] https://cdn.prod.website-files.com/6723c4704dc317b68172e019/67366167981794e9ead61adf_40489856166.pdf