Content Menu

● Understanding Aluminum Walk Boards

● Factors to Consider When Choosing Aluminum Walk Boards

>> 1. Load Capacity

>> 2. Dimensions

>> 3. Surface Texture

>> 4. End Caps

>> 5. Compatibility

>> 6. Compliance with Safety Standards

● Types of Aluminum Walk Boards

>> 1. Standard Aluminum Walk Boards

>> 2. Heavy-Duty Aluminum Walk Boards

>> 3. Lightweight Aluminum Walk Boards

>> 4. Customizable Aluminum Walk Boards

● Maintenance and Care

● Top Manufacturers of Aluminum Walk Boards

● Cost Considerations

● Case Studies

>> Case Study 1: High-Rise Construction Project

>> Case Study 2: Historic Building Restoration

● Environmental Impact

● Future Trends in Aluminum Walk Boards

● Conclusion

● FAQ

>> 1. How long do aluminum walk boards typically last?

>> 2. Can aluminum walk boards be used in all weather conditions?

>> 3. Are aluminum walk boards more expensive than wooden planks?

>> 4. How often should aluminum walk boards be inspected?

>> 5. Can aluminum walk boards be customized for specific project needs?

● Citations:

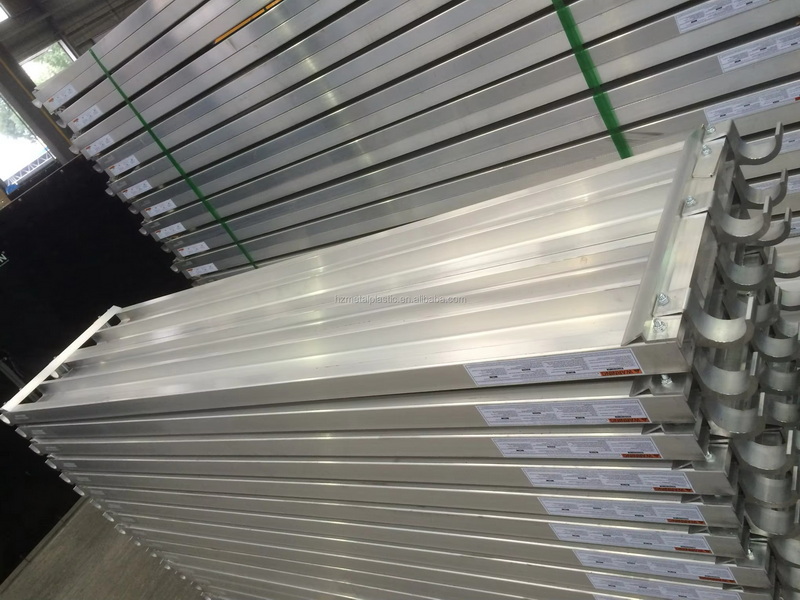

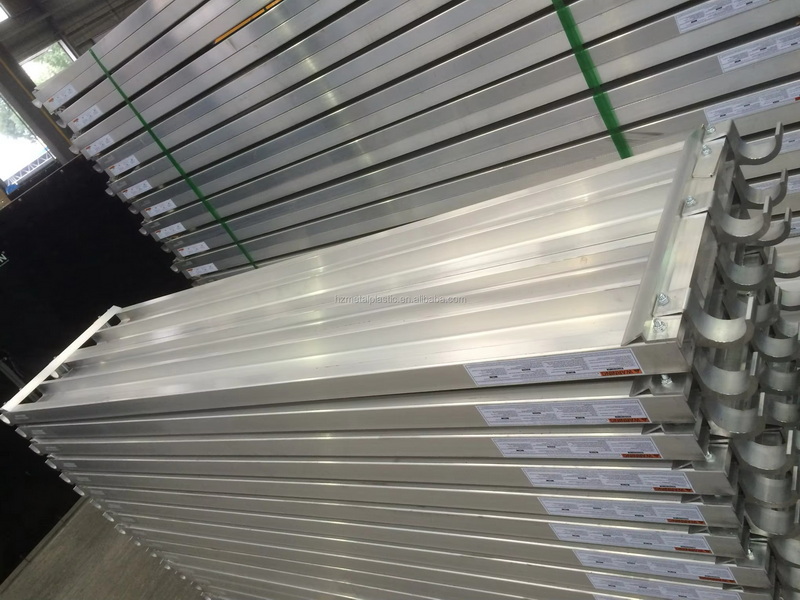

Aluminum walk boards are essential components of scaffolding systems, providing safe and stable platforms for workers to move and work at heights. Choosing the right aluminum walk boards is crucial for ensuring worker safety and project efficiency. This comprehensive guide will help you understand the key factors to consider when selecting the best aluminum walk boards for your scaffolding needs.

Understanding Aluminum Walk Boards

Aluminum walk boards, also known as scaffold planks or stage boards, are lightweight yet durable platforms used in scaffolding systems. They offer several advantages over traditional wooden planks, including:

- Rust and corrosion resistance

- Non-flammability

- Resistance to rotting and splintering

- Lightweight and portable design

- Easy setup and adjustment

- Excellent non-slip surfaces

- Resistance to twisting and buckling

Factors to Consider When Choosing Aluminum Walk Boards

1. Load Capacity

One of the most critical factors in selecting aluminum walk boards is their load capacity. Different projects and applications require varying weight-bearing capabilities. Common load capacities include:

- 250 lbs

- 500 lbs

- 750 lbs

Always choose walk boards that exceed the expected load to ensure safety. Consider both the weight of workers and any equipment or materials they may need to carry.

2. Dimensions

Aluminum walk boards come in various sizes to suit different scaffolding configurations:

- Widths: Typically range from 12" to 28"

- Lengths: Available from 8' to 32'

Select dimensions that provide adequate working space while fitting your specific scaffolding setup.

3. Surface Texture

A non-slip surface is crucial for worker safety. Look for aluminum walk boards with:

- Raised or abraded surfaces

- Tread patterns that promote water drainage

These features enhance traction and reduce the risk of slips and falls.

4. End Caps

Vinyl-coated end caps serve multiple purposes:

- Act as hand grips for easy carrying

- Protect against sharp edges

- Prevent surface marks on walls or other structures

Ensure the walk boards you choose have durable, well-designed end caps.

5. Compatibility

Verify that the aluminum walk boards are compatible with your existing scaffolding system. They should work well with:

- Pump jack scaffolds

- Ladder jacks

- Catwalks

- Narrow and wide span aluminum scaffolding

6. Compliance with Safety Standards

Ensure the aluminum walk boards meet or exceed relevant safety standards, such as:

- OSHA regulations

- ANSI standards

- Local building codes

Types of Aluminum Walk Boards

1. Standard Aluminum Walk Boards

These are the most common type, suitable for general scaffolding applications. They offer a good balance of strength, weight, and cost-effectiveness.

2. Heavy-Duty Aluminum Walk Boards

Designed for high-load applications, these walk boards can support greater weights and are ideal for industrial or commercial projects.

3. Lightweight Aluminum Walk Boards

Perfect for situations where minimal weight is crucial, these boards are easy to transport and maneuver, making them ideal for residential or small-scale projects.

4. Customizable Aluminum Walk Boards

Some manufacturers offer custom-sized walk boards to fit unique scaffolding configurations or specific project requirements.

Maintenance and Care

Proper maintenance of aluminum walk boards ensures their longevity and continued safety:

1. Regular inspections for damage or wear

2. Cleaning to remove debris and maintain non-slip surfaces

3. Proper storage in dry conditions when not in use

4. Avoiding exposure to corrosive substances

Top Manufacturers of Aluminum Walk Boards

Several reputable companies produce high-quality aluminum walk boards for scaffolding:

1. Werner

2. REDD Team

3. Altrex

4. Louisville Ladder

5. Metaltech

Research these manufacturers and compare their products to find the best fit for your needs.

Cost Considerations

While aluminum walk boards may have a higher upfront cost compared to wooden planks, they offer long-term benefits:

- Longer lifespan

- Reduced maintenance costs

- Improved safety features

- Potential for bulk discounts on large orders

Consider the total cost of ownership when making your decision.

Case Studies

Case Study 1: High-Rise Construction Project

A major construction company chose heavy-duty aluminum walk boards for a 50-story building project. The boards' high load capacity and durability allowed workers to safely transport materials and equipment, resulting in improved efficiency and zero scaffolding-related accidents.

Case Study 2: Historic Building Restoration

A restoration team selected lightweight aluminum walk boards for work on a delicate historic structure. The boards' low weight minimized stress on the building while providing stable platforms for intricate restoration work.

Environmental Impact

Aluminum walk boards offer environmental benefits compared to wooden alternatives:

- Recyclable material

- Longer lifespan reduces waste

- No need for treatments with harmful chemicals

Consider these factors if sustainability is a priority for your project.

Future Trends in Aluminum Walk Boards

The scaffolding industry continues to innovate, with potential future developments including:

1. Smart sensors for load monitoring

2. Integration with digital project management tools

3. Advanced materials for even lighter weight and higher strength

4. Improved ergonomic designs for worker comfort

Stay informed about these trends to ensure you're always using the best available technology.

Conclusion

Choosing the best aluminum walk boards for scaffolding requires careful consideration of factors such as load capacity, dimensions, surface texture, and compliance with safety standards. By understanding these key elements and the various types of aluminum walk boards available, you can make an informed decision that prioritizes worker safety and project efficiency.

Remember to regularly inspect and maintain your aluminum walk boards to ensure their continued performance and safety. With the right selection and proper care, aluminum walk boards can provide a durable, reliable, and cost-effective solution for your scaffolding needs.

FAQ

1. How long do aluminum walk boards typically last?

With proper maintenance and care, high-quality aluminum walk boards can last 10 years or more. Their durability and resistance to corrosion make them a long-lasting investment compared to wooden alternatives.

2. Can aluminum walk boards be used in all weather conditions?

Aluminum walk boards are generally suitable for use in various weather conditions due to their corrosion resistance. However, extreme temperatures or icy conditions may require additional safety measures. Always follow manufacturer guidelines and conduct a risk assessment before use in adverse weather.

3. Are aluminum walk boards more expensive than wooden planks?

Initially, aluminum walk boards may have a higher cost than wooden planks. However, their longer lifespan, reduced maintenance needs, and improved safety features often make them more cost-effective in the long run.

4. How often should aluminum walk boards be inspected?

Aluminum walk boards should be visually inspected before each use. Additionally, a thorough inspection by a qualified person should be conducted regularly, typically every 3-6 months or after any incident that may have damaged the board.

5. Can aluminum walk boards be customized for specific project needs?

Yes, many manufacturers offer customization options for aluminum walk boards. This can include specific dimensions, load capacities, or surface textures to meet unique project requirements. Contact manufacturers directly to discuss customization possibilities.

Citations:

[1] https://www.reddteam.com/aluminum-walk-boards.html

[2] https://www.associated-scaffolding.com/sales/werner-aluminum-walkboard-stages

[3] https://scaffoldingrentalandsales.com/blog/the-aluminum-walk-board-vs-traditional-boards/

[4] https://www.sparsteel.com/blog/scaffolding-steel-boards-types-features-uses-benefits/

[5] https://www.alibaba.com/showroom/aluminum-scaffolding-walk-boards.html

[6] https://www.alibaba.com/product-detail/_1600624375282.html