Content Menu

● Introduction to Scaffolding Couplers

● Types of Scaffolding Couplers

● Choosing the Right Joint Coupler

>> Safety Considerations

>> Best Practices for Installation

● Advanced Scaffolding Techniques

>> Modular Scaffolding Systems

>> Cantilever Scaffolding

>> Suspended Scaffolding

● Case Studies

>> Example 1: High-Rise Building Maintenance

>> Example 2: Event Scaffolding

● Conclusion

● FAQ

>> 1. What are the main types of scaffolding couplers?

>> 2. How do I choose the right joint coupler for my scaffolding project?

>> 3. What safety considerations should I keep in mind when using scaffolding couplers?

>> 4. What are the benefits of using swivel couplers in scaffolding?

>> 5. How do I ensure the proper installation of joint couplers?

● Citations:

Choosing the right joint coupler for scaffolding projects is crucial for ensuring the stability, safety, and efficiency of scaffolding systems. Scaffolding couplers are essential components that connect scaffold tubes, providing structural integrity and support. In this article, we will explore the different types of joint couplers, their applications, and how to select the appropriate one for your scaffolding needs.

Introduction to Scaffolding Couplers

Scaffolding couplers are designed to connect scaffold tubes securely, allowing for the construction of stable and safe scaffolding structures. They come in various types, each serving specific purposes and offering different functionalities.

Types of Scaffolding Couplers

1. Right-Angle Couplers (Double Couplers)

- Description: Right-angle couplers, also known as double couplers, are used to connect two scaffold tubes at a 90-degree angle. They are essential for forming the basic framework of scaffolding structures and provide strong load-bearing capacity.

- Use: These couplers are primarily used in load-bearing applications, such as forming the standard of the scaffold, and are excellent for vertical and horizontal connections.

- Key Features: Strong load-bearing capacity, excellent for vertical and horizontal connections, essential for primary structural stability.

2. Swivel Couplers

- Description: Swivel couplers are versatile connectors that enable the connection of scaffold tubes at any angle within a 360-degree range. They feature two clamps that can be tightened to secure the tubes firmly in place.

- Use: Swivel couplers are particularly useful when constructing complex scaffold configurations that require flexibility and adaptability.

- Key Features: Versatile, allows connection at any angle, useful for complex configurations.

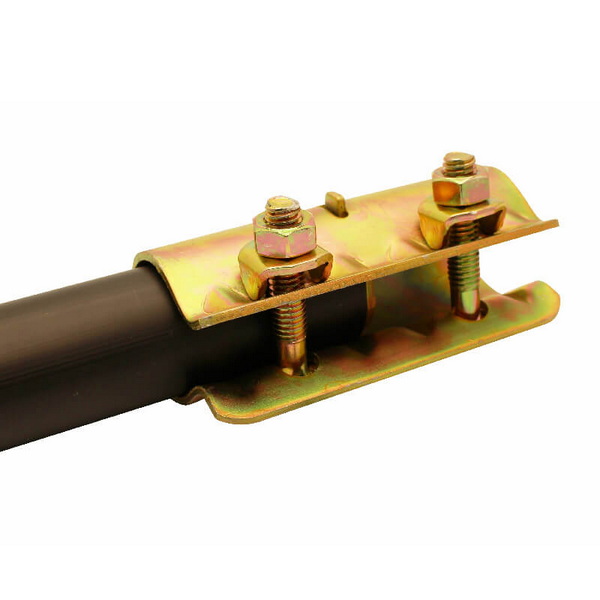

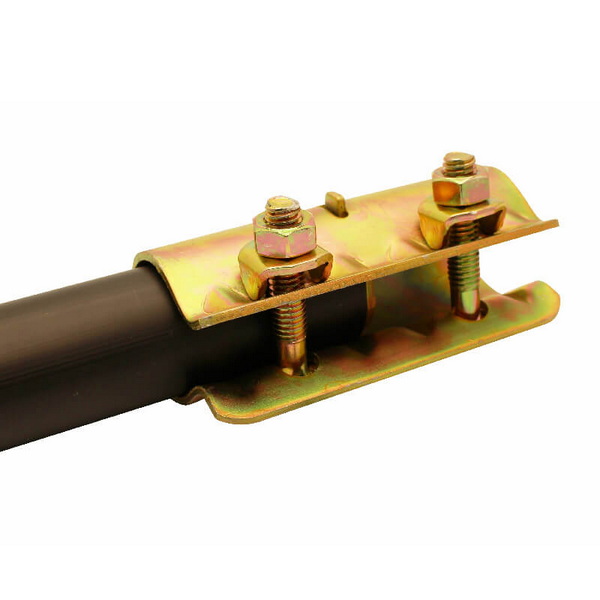

3. Sleeve Couplers

- Description: Sleeve couplers, also referred to as joiners or internal couplers, are employed to connect scaffold tubes end-to-end. These couplers slide over the tubes and are secured using bolts or pins.

- Use: Sleeve couplers are commonly utilized when scaffolding requires longer spans or when two tubes need to be joined together to achieve the desired length.

- Key Features: Connects tubes end-to-end, useful for longer spans.

4. Putlog Couplers

- Description: Putlog couplers, also known as single couplers or single right-angle couplers, serve the purpose of attaching transoms or putlogs to ledger tubes. With a single clamp mechanism, they effectively secure the putlog or transom tube to the ledger tube.

- Use: Putlog couplers are typically used in scaffolding configurations where a scaffold platform is constructed on one side of a structure.

- Key Features: Attaches transoms to ledger tubes, used in one-sided scaffolding.

5. Beam Couplers

- Description: Beam couplers, or girder couplers, connect scaffolding tubes to beams or girders. They are essential for integrating scaffolding with existing structural elements.

- Use: These couplers are used to secure scaffolding to beams, providing additional stability and support.

- Key Features: Connects scaffolding to beams, enhances stability.

6. Board Retaining Couplers

- Description: Board retaining couplers secure scaffold boards in place, preventing them from slipping. They are crucial for maintaining a safe working platform.

- Use: These couplers ensure that scaffold boards remain securely positioned, reducing the risk of accidents.

- Key Features: Secures scaffold boards, enhances safety.

Choosing the Right Joint Coupler

When selecting a joint coupler for your scaffolding project, consider the following factors:

- Load Capacity: Ensure the coupler can handle the expected load of the scaffolding structure.

- Angle Requirements: Determine if you need couplers that can connect tubes at specific angles or if flexibility is required.

- Type of Scaffolding: Different scaffolding configurations may require specific types of couplers (e.g., putlog couplers for one-sided scaffolding).

- Safety Standards: Ensure that the couplers meet local safety standards and regulations.

Safety Considerations

Safety is paramount when working with scaffolding. Proper use and inspection of couplers are critical to prevent accidents. Always follow these safety tips:

- Regular Inspection: Regularly inspect couplers for damage or wear.

- Correct Installation: Ensure couplers are installed correctly according to manufacturer guidelines.

- Training: Ensure all personnel are trained in the proper use and handling of scaffolding couplers.

Best Practices for Installation

To maximize the effectiveness and safety of your scaffolding structure, follow these best practices for installing joint couplers:

1. Follow Manufacturer Instructions: Always refer to the manufacturer's guidelines for specific installation procedures.

2. Use Proper Tools: Use the correct tools to secure couplers to prevent damage or improper tightening.

3. Test the Structure: Before use, test the scaffolding structure to ensure it is stable and secure.

Advanced Scaffolding Techniques

In addition to selecting the right couplers, understanding advanced scaffolding techniques can enhance the efficiency and safety of your projects.

Modular Scaffolding Systems

Modular scaffolding systems use pre-fabricated components that can be easily assembled and disassembled. These systems often rely on specialized couplers designed for quick connection and disconnection.

- Advantages: Modular systems are highly efficient, reducing setup and teardown times. They are ideal for projects requiring frequent reconfiguration.

- Use: Suitable for large-scale construction projects or events where scaffolding needs to be erected and dismantled quickly.

Cantilever Scaffolding

Cantilever scaffolding involves extending the scaffold platform beyond the base of the structure. This technique requires specialized couplers that can handle the additional stress and weight.

- Use: Commonly used in situations where access is limited or when working on structures with overhangs.

- Key Features: Requires strong and durable couplers to ensure stability.

Suspended Scaffolding

Suspended scaffolding involves hanging the scaffold platform from a building or structure. This method requires couplers that can securely attach to overhead supports.

- Use: Often used for exterior maintenance or repairs on high-rise buildings.

- Key Features: Couplers must be capable of supporting heavy loads while maintaining flexibility.

Case Studies

Example 1: High-Rise Building Maintenance

In a recent project involving the maintenance of a high-rise building, swivel couplers were used to construct a complex scaffold configuration that allowed workers to access multiple areas of the facade. The versatility of these couplers enabled the team to adapt the scaffolding to the building's unique architectural features.

Example 2: Event Scaffolding

For a large outdoor event, modular scaffolding systems were employed to quickly erect and dismantle stages and viewing platforms. The use of specialized couplers designed for modular systems significantly reduced setup times, allowing the event to proceed smoothly.

Conclusion

Choosing the right joint coupler for scaffolding projects is essential for ensuring safety, stability, and efficiency. By understanding the different types of couplers and their applications, you can select the appropriate coupler for your specific needs. Always prioritize safety and follow best practices for installation to ensure a successful project.

FAQ

1. What are the main types of scaffolding couplers?

The main types of scaffolding couplers include right-angle couplers, swivel couplers, sleeve couplers, putlog couplers, beam couplers, and board retaining couplers. Each type serves specific purposes and offers different functionalities.

2. How do I choose the right joint coupler for my scaffolding project?

To choose the right joint coupler, consider factors such as load capacity, angle requirements, type of scaffolding, and safety standards. Ensure the coupler meets local safety regulations and is suitable for the specific scaffolding configuration.

3. What safety considerations should I keep in mind when using scaffolding couplers?

Safety considerations include regular inspection of couplers for damage, correct installation according to manufacturer guidelines, and ensuring all personnel are trained in the proper use and handling of scaffolding couplers.

4. What are the benefits of using swivel couplers in scaffolding?

Swivel couplers offer versatility by allowing connections at any angle within a 360-degree range. They are particularly useful for complex scaffold configurations that require flexibility and adaptability.

5. How do I ensure the proper installation of joint couplers?

Ensure proper installation by following manufacturer instructions, using the correct tools, and testing the scaffolding structure before use to ensure it is stable and secure.

Citations:

[1] https://shelterrc.com/scaffolding-couplers-types-a-comprehensive-guide/

[2] https://www.youtube.com/watch?v=a5VG7k_boDs

[3] https://www.bbc.com/learningenglish/chinese/features/q-and-a/ep-200318

[4] https://www.linkedin.com/pulse/comprehensive-guide-types-couplers-scaffolding-abhishek-mishra

[5] https://www.youtube.com/watch?v=D3U9C58KEpk

[6] https://www.sohu.com/a/647847515_121236633

[7] https://apacsafety.com/the-ultimate-guide-of-scaffolding-couplers/

[8] https://www.youtube.com/watch?v=mO8Uh3LP4kk

[9] https://patents.google.com/patent/CN101053134B/zh

[10] https://wslindia.com/types-of-scaffolding-couplers/

[11] https://www.wm-scaffold.com/scaffolding-coupler.html