Content Menu

● Introduction to Scaffolding Couplers

● Types of Scaffolding Couplers

>> Right-Angle Couplers (Double Couplers)

>> Swivel Couplers

>> Sleeve Couplers

>> Putlog Couplers

>> Board Retaining Couplers

>> Beam/Girder Couplers

● Key Factors to Consider When Choosing a Scaffolding Coupler

>> Load-Bearing Requirements

>> Angle and Position Requirements

>> Length Adjustments

>> Environmental Conditions

>> Compliance and Safety Standards

● Load Capacity and Safety Standards

● Materials and Durability

● Installation and Compatibility

● Environmental and Project-Specific Considerations

● Where to Find Scaffolding Couplers for Sale

● Maintenance and Inspection

● Common Mistakes to Avoid

● Conclusion

● FAQ

>> 1. What are the most common types of scaffolding couplers for sale?

>> 2. How do I know which scaffolding coupler is right for my project?

>> 3. Are all scaffolding couplers compatible with standard scaffold tubes?

>> 4. Can I use swivel couplers for load-bearing connections?

>> 5. Where can I buy certified scaffolding couplers for sale?

Choosing the right scaffolding coupler is a critical decision that affects the safety, stability, and efficiency of your scaffolding structure. With a wide variety of scaffolding couplers for sale on the market, understanding their types, functions, load capacities, and suitable applications is essential for any construction or maintenance project.

Introduction to Scaffolding Couplers

Scaffolding couplers, also known as scaffolding clamps, are mechanical devices used to connect scaffold tubes securely. They are fundamental components in tube and clamp scaffolding systems, enabling the construction of safe, stable, and adaptable scaffold structures. The right scaffolding coupler ensures that tubes are firmly connected at the correct angles and positions, supporting the load and resisting forces like wind and vibration.

Tube and coupler scaffolding is known for its adaptability, capable of conforming to irregular work surfaces and project specifications.

Types of Scaffolding Couplers

Understanding the types of scaffolding couplers available is the first step in choosing the right one for your project. Here are the most common types:

Right-Angle Couplers (Double Couplers)

Right-angle couplers connect two scaffold tubes at a 90-degree angle, forming the backbone of most scaffolding frameworks. They provide strong, rigid joints essential for vertical and horizontal connections.

- Use: Load-bearing applications such as standards and ledgers.

- Features: High load capacity, fixed angle connection.

Swivel Couplers

Swivel couplers connect tubes at any angle within a 360-degree range. Their flexibility allows for complex scaffold designs, diagonal bracing, and irregular structures.

- Use: Diagonal braces, complex scaffolding geometries.

- Features: Adjustable angle, versatile connection.

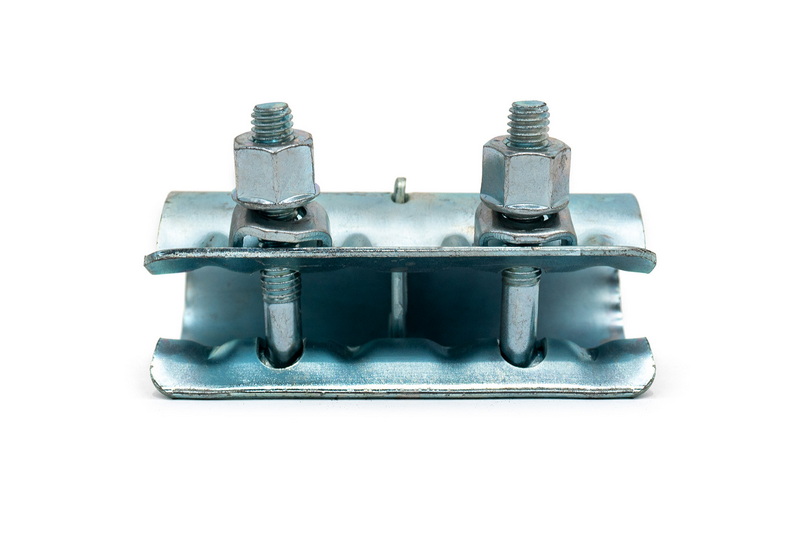

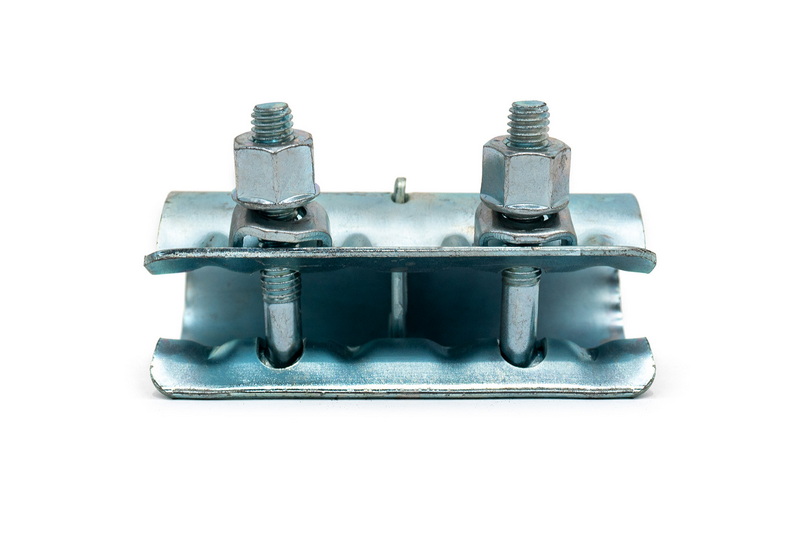

Sleeve Couplers

Sleeve couplers join two tubes end-to-end, extending the length of scaffold members. They slide over the tube ends and are tightened securely.

- Use: Extending scaffold runs or replacing damaged sections.

- Features: Seamless connection, strong axial load resistance.

Putlog Couplers

Putlog couplers attach putlog tubes to ledgers or standards, usually supporting scaffold boards or platforms on one side of a structure.

- Use: Non-load-bearing connections, platform support.

- Features: Single clamp, cost-effective.

Board Retaining Couplers

These couplers secure scaffold boards to prevent movement, enhancing platform safety.

Beam/Girder Couplers

Beam couplers connect scaffold tubes to steel girders or beams, allowing scaffolding to be tied into existing structures.

Key Factors to Consider When Choosing a Scaffolding Coupler

Load-Bearing Requirements

Determine the maximum load your scaffold will need to support. For primary structural connections, such as standards and ledgers, right-angle (double) couplers with high load capacity are essential. Swivel couplers, while versatile, are typically not used for main load-bearing joints.

Angle and Position Requirements

If your scaffold design requires tubes to join at angles other than 90 degrees, swivel couplers are the right choice. For straightforward perpendicular connections, right-angle couplers suffice.

Length Adjustments

When you need to extend scaffold tubes or repair damaged sections, sleeve couplers provide a secure end-to-end connection.

Environmental Conditions

In windy or outdoor environments, consider using board retaining couplers to secure platforms and prevent accidents. Also, ensure couplers have corrosion-resistant finishes like hot-dip galvanizing for durability.

Compliance and Safety Standards

Always choose scaffolding couplers that comply with local and international safety standards such as BS 1139, EN 74, OSHA, or AS 1576. This ensures reliability and legal compliance.

OSHA emphasizes the importance of using trained workers, level footings, proper bracing, and regular inspections to maintain safety when using tube and coupler scaffolds.

Load Capacity and Safety Standards

Scaffolding couplers must support significant loads safely. The Working Load Limit (WLL) is a crucial specification indicating the maximum load a coupler can bear.

Coupler Type | Typical WLL (kN) | Application |

Right-Angle Coupler | 6.25 | Load-bearing joints |

Swivel Coupler | 6.25 | Flexible angled joints |

Sleeve Coupler | 12.5 | Tube extensions |

Putlog Coupler | 0.62 | Non-load-bearing platform support |

Proper tightening torque (usually around 54 Nm) is essential to achieve these load capacities and prevent slippage or failure.

Materials and Durability

Most scaffolding couplers are made from high-strength forged steel or pressed steel, providing durability and load resistance. Hot-dip galvanizing is a common finish that protects couplers from corrosion, especially in outdoor or harsh environments.

Installation and Compatibility

Choosing the right coupler also involves ensuring compatibility with your scaffold tubes, which typically have an outer diameter of 48.3mm (standard tube size). Some specialized scaffolding systems may use different tube sizes, requiring matching couplers.

Proper installation requires:

- Correct positioning of couplers on tubes

- Tightening to recommended torque using a scaffold spanner

- Regular inspection to ensure tightness and integrity

Environmental and Project-Specific Considerations

- Indoor vs. Outdoor: Outdoor projects require corrosion-resistant couplers.

- Height and Complexity: Taller or complex scaffolds may need swivel couplers and specialized beam couplers.

- Load Type: Heavy-duty projects require couplers with higher load ratings.

- Budget: While safety is paramount, cost-effective couplers like pressed steel may be suitable for light-duty applications.

Where to Find Scaffolding Couplers for Sale

When purchasing scaffolding couplers for sale, consider reputable manufacturers and suppliers who provide certified, tested products. Online marketplaces, scaffolding specialists, and construction equipment distributors are common sources.

Always verify product certifications and compliance with safety standards before purchase.

Maintenance and Inspection

Regular maintenance and inspection are critical to ensure the continued safety and reliability of scaffolding couplers.

- Daily Inspection: Before each shift, inspect all couplers for signs of damage, corrosion, or wear.

- Tightness Check: Ensure that all couplers are tightened to the recommended torque. Use a calibrated torque wrench to verify.

- Cleaning: Keep couplers free from dirt, debris, and rust. Clean them periodically using a wire brush and apply a rust inhibitor.

- Replacement: Replace any couplers that show signs of damage, such as cracks, deformation, or severe corrosion.

- Storage: Store couplers in a dry, covered location to prevent corrosion.

Common Mistakes to Avoid

- Over-Tightening: Over-tightening couplers can damage the threads and reduce their load-bearing capacity. Always use a calibrated torque wrench and follow the manufacturer's recommendations.

- Mixing Coupler Types: Using different types of couplers in the same scaffold structure can compromise its integrity. Ensure that all couplers are compatible and designed for the intended application.

- Neglecting Inspections: Failing to inspect couplers regularly can lead to undetected damage and potential failures. Implement a rigorous inspection program and train workers to identify common issues.

- Using Non-Certified Couplers: Using couplers that do not meet recognized safety standards can significantly increase the risk of accidents. Always purchase couplers from reputable suppliers and verify their certifications.

- Improper Installation: Incorrect installation of couplers can reduce their load capacity and stability. Follow the manufacturer's instructions and ensure that workers are properly trained.

Conclusion

Choosing the right scaffolding coupler for your project is essential for ensuring a safe, stable, and efficient scaffolding structure. By understanding the types of couplers available, their load capacities, material properties, and compatibility with your scaffold design, you can make informed decisions that enhance safety and productivity. Always prioritize couplers that meet established safety standards and ensure proper installation and maintenance. With the right scaffolding coupler for sale, your project will stand on a strong foundation.

FAQ

1. What are the most common types of scaffolding couplers for sale?

The most common types include right-angle (double) couplers, swivel couplers, sleeve couplers, putlog couplers, and beam/girder couplers.

2. How do I know which scaffolding coupler is right for my project?

Consider factors such as load requirements, angle of connection, scaffold design complexity, and compliance with safety standards.

3. Are all scaffolding couplers compatible with standard scaffold tubes?

Most couplers are designed for standard 48.3mm diameter tubes, but specialized systems may require specific couplers.

4. Can I use swivel couplers for load-bearing connections?

Swivel couplers are versatile but are generally not recommended for primary load-bearing joints due to their adjustable nature.

5. Where can I buy certified scaffolding couplers for sale?

Certified couplers can be purchased from reputable scaffolding suppliers, manufacturers, and online marketplaces that provide compliance documentation.