Content Menu

● Introduction to Cuplock Scaffolding Design

● Key Principles of Customizing Cuplock Scaffolding

>> 1. Modularity and Adaptability

>> 2. Node-Point Locking System

>> 3. Load-Bearing and Stability

>> 4. Compliance and Safety

● Step-by-Step Process for Custom Cuplock Scaffolding Design

>> Step 1: Project Assessment and Requirements Gathering

>> Step 2: System Layout and 3D Modeling

>> Step 3: Component Selection and Customization

>> Step 4: Structural Analysis and Load Calculations

>> Step 5: Assembly Sequencing and Site Logistics

>> Step 6: Safety Integration and Compliance Checks

● Essential Components and Customization Options

>> 1. Standards (Verticals)

>> 2. Ledgers (Horizontals)

>> 3. Transoms and Braces

>> 4. Hop-Up Brackets and Cantilever Frames

>> 5. Base Jacks and Adjustable Plates

>> 6. Special Accessories

● Advanced Strategies for Complex Cuplock Scaffolding Design

>> 1. Integrating BIM and Digital Design Tools

>> 2. Modular Prefabrication and Offsite Assembly

>> 3. Hybrid Systems and Integration

>> 4. Environmental and Site-Specific Adaptations

>> 5. Safety Enhancements and Worker Access

● Case Studies: Complex Cuplock Scaffolding Design in Action

>> Case Study 1: Curved Facade on a High-Rise

>> Case Study 2: Multi-Level Industrial Plant

>> Case Study 3: Bridge with Variable Heights and Cantilevers

● Safety, Compliance, and Best Practices

>> 1. Adherence to Standards

>> 2. Professional Engineering Review

>> 3. Worker Training and Site Supervision

>> 4. Regular Inspection and Maintenance

● Conclusion

● FAQ

>> 1. What makes cuplock scaffolding design suitable for complex projects?

>> 2. How can I ensure my custom cuplock scaffolding design is safe and compliant?

>> 3. What are some common custom components used in cuplock scaffolding design?

>> 4. Can cuplock scaffolding design be used for both indoor and outdoor projects?

>> 5. What software tools are used for advanced cuplock scaffolding design?

Cuplock scaffolding is renowned for its modularity, strength, and adaptability, making it a top choice for complex construction projects worldwide. However, when faced with unique architectural challenges—such as curved facades, irregular footprints, multi-level platforms, or heavy load requirements—standard configurations may not suffice. This comprehensive guide will demonstrate how to customize cuplock scaffolding design for complex projects, covering principles, strategies, real-world examples, and expert tips.

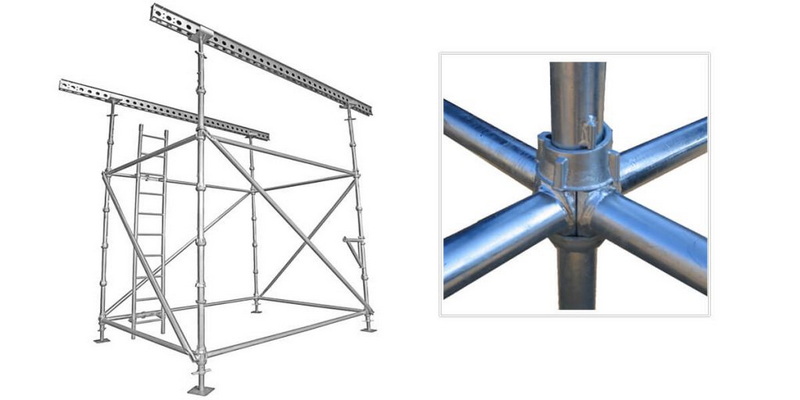

Introduction to Cuplock Scaffolding Design

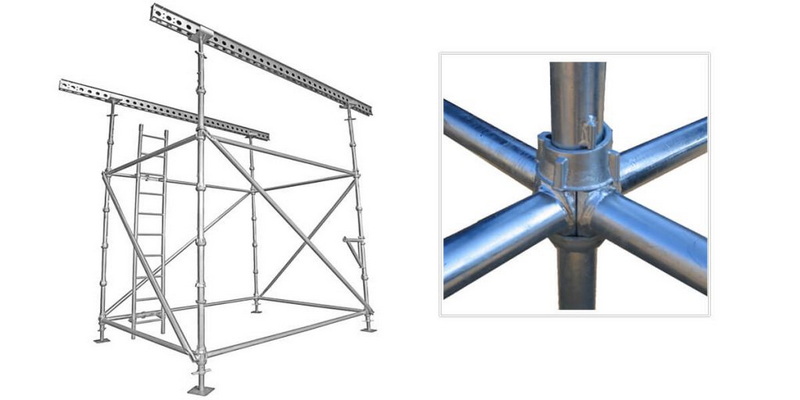

Cuplock scaffolding design is based on a modular system featuring vertical standards, horizontal ledgers, and a unique cup-node locking mechanism. Its hallmark is flexibility: up to four horizontals can be locked into a single node point, enabling rapid assembly and robust structural integrity. This makes cuplock systems ideal for large-scale and complex projects, from skyscrapers and bridges to industrial plants and infrastructure.

Key Principles of Customizing Cuplock Scaffolding

1. Modularity and Adaptability

The modular nature of cuplock scaffolding allows for easy adaptation to a wide variety of geometries—straight, curved, circular, or multi-level. By combining standard and custom components, you can configure the system to fit virtually any architectural requirement.

2. Node-Point Locking System

The circular cup-node connection is the heart of the cuplock system, allowing up to four horizontals to be locked at a single point. This enables secure, multi-directional connections, essential for complex layouts and load paths.

3. Load-Bearing and Stability

Custom designs must account for load distribution, especially in heavy-duty or cantilevered applications. Double scaffolding, additional braces, and reinforced standards may be required for high-load or high-rise projects.

4. Compliance and Safety

All customizations must adhere to international standards (EN12810, EN12811, BS1139) and local regulations to ensure safety and structural integrity.

Step-by-Step Process for Custom Cuplock Scaffolding Design

Step 1: Project Assessment and Requirements Gathering

- Analyze architectural drawings, site conditions, and project specifications.

- Identify unique challenges: curved facades, variable heights, heavy loads, restricted access, etc.

- Consult with engineers and cuplock scaffolding design experts.

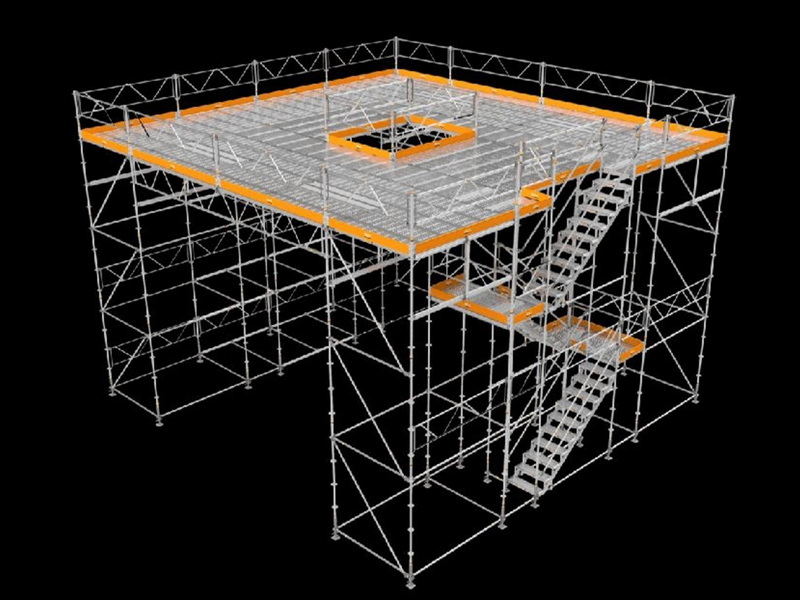

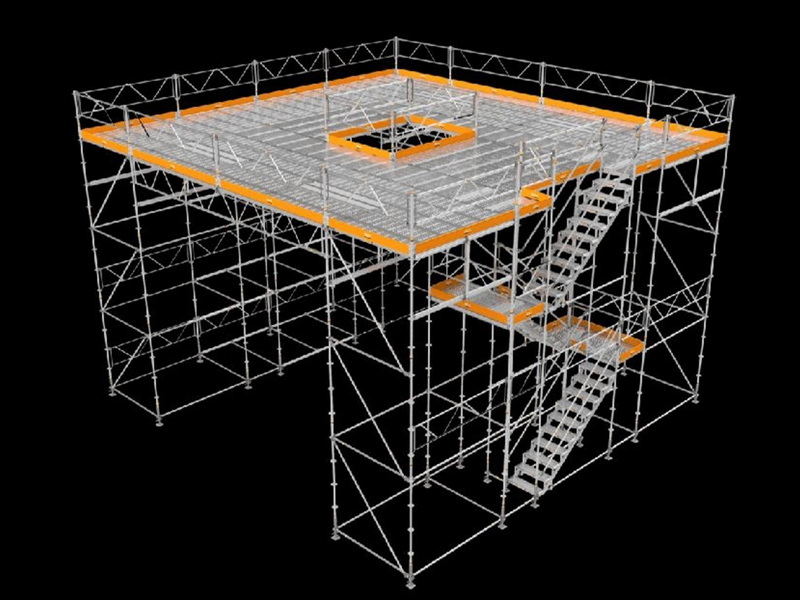

Step 2: System Layout and 3D Modeling

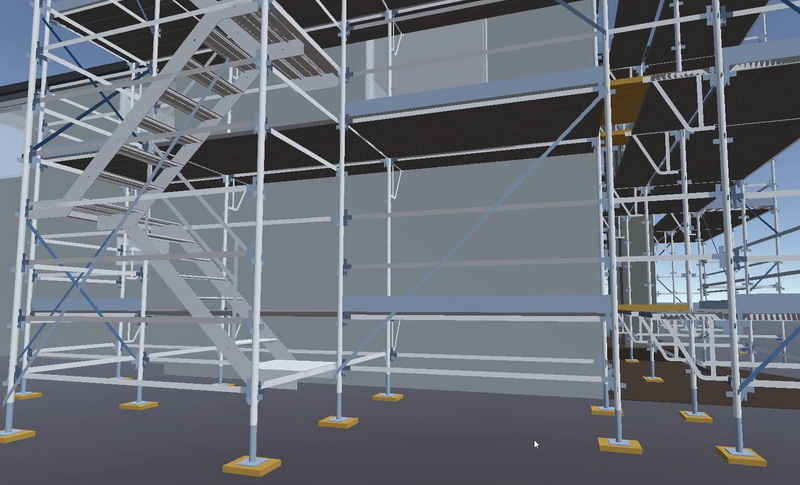

- Use CAD or BIM software to create a digital model of the scaffolding system.

- Map out all standards, ledgers, transoms, braces, and platforms, adjusting for irregular shapes and obstructions.

- Simulate load paths and check for compliance with safety standards.

Step 3: Component Selection and Customization

- Select standard cuplock components where possible for efficiency and cost savings.

- Design custom components (e.g., special-length ledgers, curved transoms, hop-up brackets) for non-standard areas.

- Specify material grades (S355, Q345 steel) and finishes (hot-dip galvanized for durability).

Step 4: Structural Analysis and Load Calculations

- Perform detailed structural analysis to ensure the scaffold can safely support expected loads, including workers, materials, and equipment.

- Factor in wind loads, dynamic forces, and potential impact loads in exposed or high-rise settings.

Step 5: Assembly Sequencing and Site Logistics

- Plan the order of assembly, accounting for site access, crane or forklift requirements, and safety zones.

- Prepare detailed erection and dismantling procedures, especially for confined or high-traffic sites.

Step 6: Safety Integration and Compliance Checks

- Integrate guardrails, toe boards, stair towers, and access platforms as required.

- Conduct pre-assembly safety reviews and obtain necessary approvals from safety authorities.

Essential Components and Customization Options

1. Standards (Verticals)

- Standard sizes: 500mm to 3000mm, 48.3mm diameter, 3.2mm or 3.5mm wall thickness.

- Custom lengths or reinforced standards for special height or load requirements.

2. Ledgers (Horizontals)

- Standard lengths: 1000mm to 2500mm.

- Custom lengths for irregular bay sizes or non-orthogonal layouts.

3. Transoms and Braces

- Used for additional support and to accommodate platforms at varying widths or angles.

- Curved or angled transoms can be fabricated for circular or elliptical structures.

4. Hop-Up Brackets and Cantilever Frames

- Allow for platforms at intermediate levels or for extending platforms beyond the main frame (e.g., for facade work or overhangs).

- Custom brackets can be designed for unique access requirements.

5. Base Jacks and Adjustable Plates

- Provide fine height adjustments and stability on uneven ground.

6. Special Accessories

- Return devices, inside board transoms, and corner platforms for handling corners and projections.

- Staircases, loading bays, birdcages, and mobile towers for specialized access or support needs.

Advanced Strategies for Complex Cuplock Scaffolding Design

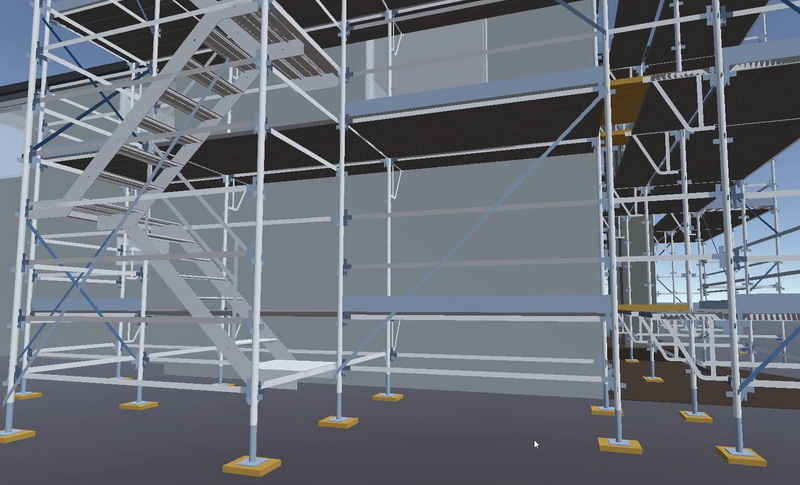

1. Integrating BIM and Digital Design Tools

Modern complex projects benefit greatly from Building Information Modeling (BIM) and advanced CAD tools. These technologies allow for:

- Precise visualization: Detecting clashes, optimizing layouts, and visualizing assembly sequences.

- Load simulation: Running digital load tests to identify weak points before construction begins.

- Collaboration: Sharing designs with architects, engineers, and site managers for seamless coordination.

2. Modular Prefabrication and Offsite Assembly

For large or repetitive structures, consider prefabricating sections of the cuplock scaffolding design offsite:

- Time savings: Reduces onsite assembly time and minimizes disruption.

- Quality control: Factory conditions ensure consistent quality and safety.

- Logistics: Prefabricated modules can be delivered just-in-time, reducing site congestion.

3. Hybrid Systems and Integration

Some projects require hybrid solutions—combining cuplock scaffolding design with other systems (e.g., ringlock, tube-and-coupler, or aluminum towers) to address unique requirements such as extreme heights, unusual shapes, or high mobility.

- Transition zones: Design special adapters or transition nodes to connect different scaffold systems.

- Material optimization: Use lighter materials (e.g., aluminum) for mobile or temporary sections.

4. Environmental and Site-Specific Adaptations

Complex sites may have environmental constraints—such as wind exposure, seismic activity, or restricted foundations:

- Wind bracing: Add extra diagonal braces, tie-ins, or wind anchors for exposed sites.

- Seismic design: Consult with structural engineers for seismic-resistant scaffold layouts.

- Foundation adaptation: Use spreader plates, adjustable bases, or custom footings to distribute loads on weak or uneven ground.

5. Safety Enhancements and Worker Access

- Integrated stair towers: Ensure safe, efficient movement between scaffold levels.

- Loading bays and material hoists: Design for material handling and storage.

- Edge protection: Add guardrails, toe boards, and debris nets for maximum safety.

Case Studies: Complex Cuplock Scaffolding Design in Action

Case Study 1: Curved Facade on a High-Rise

A high-rise building with a curved glass facade required a scaffold that could precisely follow the building's contours. The cuplock scaffolding design team used:

- Custom curved transoms and ledgers to match the radius of the facade.

- 3D modeling to ensure perfect alignment and load distribution.

- Hop-up brackets for intermediate platforms, allowing glazing teams to work at multiple levels simultaneously.

Case Study 2: Multi-Level Industrial Plant

An industrial plant retrofit involved multiple levels, heavy equipment, and tight access. The solution included:

- Double cuplock scaffolding for enhanced load-bearing capacity.

- Integrated stair towers and loading bays for efficient material movement.

- Custom base jacks and bracing to accommodate uneven floors and overhead obstructions.

Case Study 3: Bridge with Variable Heights and Cantilevers

A highway bridge project required scaffolding at different heights and with cantilevered sections for formwork support. The cuplock scaffolding design featured:

- Variable-length standards and ledgers to match the bridge profile.

- Cantilever frames and special transoms to support overhanging platforms.

- Reinforced standards and extra bracing for high wind and load conditions.

Safety, Compliance, and Best Practices

1. Adherence to Standards

- Follow EN12810, EN12811, BS1139, OSHA, and local codes for all custom designs.

- Use only certified materials and components from reputable manufacturers.

2. Professional Engineering Review

- Engage structural engineers for all complex or high-rise cuplock scaffolding design projects.

- Conduct third-party inspections and load tests before use.

3. Worker Training and Site Supervision

- Train crews on the specific assembly, use, and dismantling procedures for custom configurations.

- Maintain clear communication and supervision throughout the project.

4. Regular Inspection and Maintenance

- Inspect all components for damage or wear before and during use.

- Replace or repair any compromised parts immediately.

Conclusion

Customizing cuplock scaffolding design for complex projects requires a blend of modular system knowledge, engineering expertise, and creative problem-solving. By leveraging the inherent flexibility of the cuplock system—through custom components, advanced modeling, and rigorous safety practices—you can address even the most challenging architectural and structural requirements. Whether for curved facades, multi-level plants, or cantilevered bridges, a well-executed cuplock scaffolding design ensures safety, efficiency, and project success. Always collaborate with experienced engineers and certified suppliers to achieve the best results, and consider digital tools and prefabrication for maximum efficiency on site.

FAQ

1. What makes cuplock scaffolding design suitable for complex projects?

Cuplock scaffolding design is modular and highly adaptable, allowing for easy customization to fit curved, multi-level, or irregular structures. The unique cup-node locking system enables secure connections in any configuration, making it ideal for challenging architectural and engineering requirements.

2. How can I ensure my custom cuplock scaffolding design is safe and compliant?

Always follow international and local standards (EN12810, EN12811, BS1139, OSHA), use certified components, and engage professional engineers for design and review. Conduct regular inspections and load tests to ensure ongoing safety.

3. What are some common custom components used in cuplock scaffolding design?

Custom components include special-length ledgers, curved or angled transoms, hop-up brackets, cantilever frames, reinforced standards, and unique base jacks. These allow the scaffold to fit complex geometries and support heavy or unusual loads.

4. Can cuplock scaffolding design be used for both indoor and outdoor projects?

Yes. Cuplock scaffolding design is suitable for both indoor and outdoor applications, including building facades, industrial plants, bridges, tunnels, and event structures. Its galvanized finish and robust construction ensure durability in all environments.

5. What software tools are used for advanced cuplock scaffolding design?

CAD and BIM software are commonly used for 3D modeling, layout planning, and load simulation. These tools help visualize the scaffold, optimize component selection, and ensure compliance with safety standards.