Content Menu

● What Is the Load Capacity of Scaffolding Clamps?

● Types of Scaffolding Clamps

● Factors Affecting Load Capacity

>> 1. Material Strength

>> 2. Design Standards

>> 3. Environmental Conditions

>> 4. Assembly Quality

● Methods to Calculate Load Capacity

>> 1. Using Manufacturer Specifications

>> 2. Load Capacity Formula

>> 3. Deflection Method

>> 4. Engineering Calculators

● Real-World Examples

>> Example 1: Dead Load Calculation

>> Example 2: Live Load Calculation

● Advanced Considerations for Clamp Capacity

>> Wind Loads

>> Compression Forces

● Safety Considerations

>> Regular Inspections

>> Adherence to Standards

>> Training Workers

● Conclusion

● FAQ

>> 1. What is the most common formula for calculating scaffolding clamp load capacity?

>> 2. How do environmental conditions affect scaffolding clamp capacity?

>> 3. Can different types of scaffolding clamps be used interchangeably?

>> 4. What are some tools available for calculating scaffolding clamp capacities?

>> 5. How often should scaffolding clamps be inspected?

● Citations:

Scaffolding clamps are integral to the stability and safety of scaffolding structures, making them essential components in construction projects. Determining the load capacity of scaffolding clamps is crucial for ensuring worker safety, maintaining structural integrity, and complying with international standards. This guide provides an in-depth exploration of factors affecting clamp capacity, calculation methods, practical examples, and safety considerations.

What Is the Load Capacity of Scaffolding Clamps?

The load capacity of scaffolding clamps refers to the maximum weight or force a clamp can safely support without compromising the structure. This capacity depends on several factors, including material strength, clamp type, environmental conditions, and assembly quality.

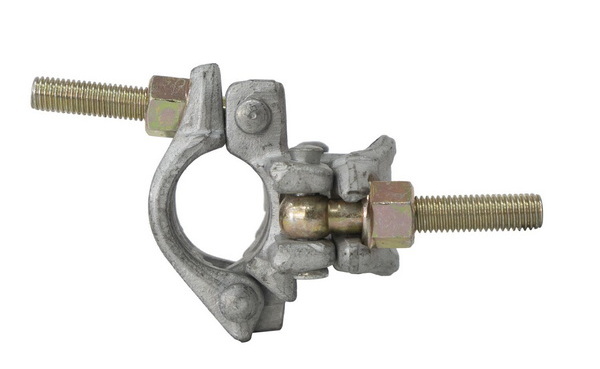

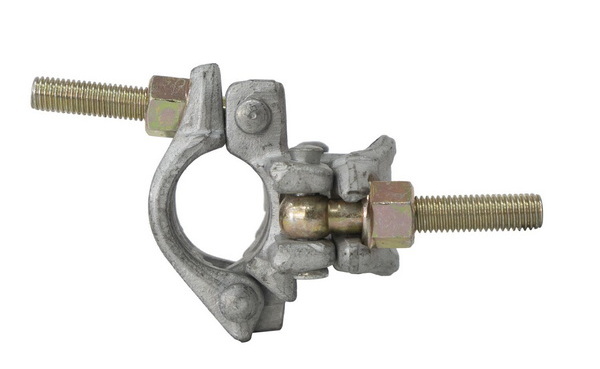

Types of Scaffolding Clamps

Scaffolding clamps come in various types, each with specific applications:

- Right-Angle Coupler: Connects tubes at 90° angles.

- Swivel Coupler: Allows tubes to connect at varying angles.

- Sleeve Coupler: Joins two tubes end-to-end.

- Parallel Coupler: Connects parallel-running tubes.

Factors Affecting Load Capacity

1. Material Strength

Scaffolding clamps are typically made from steel or aluminum. Steel clamps generally offer higher load capacities due to their superior tensile strength and durability.

2. Design Standards

International standards such as BS EN 12811-1:2003 specify minimum load capacities for different types of scaffolding clamps. Compliance with these standards ensures safety and reliability.

3. Environmental Conditions

Weather factors like wind, rain, or snow can affect scaffolding performance. For example:

- Wind loads may exert lateral forces on clamps.

- Rain or snow can increase the weight on platforms.

4. Assembly Quality

Improper assembly leads to uneven load distribution and reduced efficiency. Regular inspections are critical to maintaining structural integrity.

Methods to Calculate Load Capacity

1. Using Manufacturer Specifications

Manufacturers provide detailed load ratings based on standardized testing procedures. Always refer to these specifications as a baseline when determining scaffold clamp capacity.

2. Load Capacity Formula

The formula for calculating Safe Working Load (SWL) is:

SWL=Scaffold’s Weight Capacity/(Maximum Intended Load + Scaffold Weight)×Safety Factor

Where:

- SWL: Safe Working Load

- Safety Factor: Typically ranges from 1.1 to 1.5.

Example:

A clamp with a weight capacity of 10 kN and a maximum intended load of 8 kN would have an SWL calculated as:

SWL=10/(8+2)×1.5=7.5kN

3. Deflection Method

This method evaluates whether a scaffold platform deflects under its intended load within permissible limits (e.g., one-sixtieth of its span). A straight edge and tape measure are used for this calculation.

4. Engineering Calculators

Online tools like SkyCiv's Scaffolding Calculator allow engineers to input material properties, geometry, and design loads to determine exact load capacities.

Real-World Examples

Example 1: Dead Load Calculation

Dead loads include the weight of scaffolding components such as pipes, planks, and braces.

Calculation:

Using BS EN 39:2001 standards:

- Pipe weight: 4.5 kg/m

- Screw jack: 5 kg

- Ledgers (4 pieces): 40/2=20 kg

- Transoms (4 pieces): 32/2=16 kg

- Face brace: 18/2=9 kg

- End brace: 10/2=5 kg

- Planks (5 pieces): 100/4=25 kg

Total Dead Load Capacity:

94kg

Example 2: Live Load Calculation

Live loads account for workers' weight plus tools and materials.

Categories:

1.Light-duty scaffold: 225kg/m2

2.Medium-duty scaffold:450kg/m2

3.Heavy-duty scaffold:675kg/m2

Safe Workload (SWL):

SWL=(Dead Load Capacity)+(4×Live Load Capacity)

Advanced Considerations for Clamp Capacity

Wind Loads

Wind loads exert lateral forces that can destabilize scaffolds if not accounted for during design calculations. Engineers use wind pressure formulas such as:

P=qzCdCsCt

Where:

- qz: Velocity pressure.

- CdCsCt: Coefficients accounting for drag and shape.

Compression Forces

Compression forces can cause buckling in scaffolding tubes under heavy loads. The formula for compression resistance is:

Nc=AcfyK

Where:

- Ac: Cross-sectional area.

- fy: Yield strength.

- K: Buckling coefficient.

Safety Considerations

Regular Inspections

Inspect scaffolding clamps regularly for signs of wear or damage.

Adherence to Standards

Follow international standards such as OSHA regulations or BS EN guidelines for scaffold design and usage.

Training Workers

Ensure workers are trained in proper assembly techniques and weight distribution practices.

Conclusion

Determining the load capacity of scaffolding clamps is vital for ensuring structural stability and worker safety in construction projects. By understanding material properties, using accurate formulas, adhering to safety standards, and conducting regular inspections, you can effectively calculate and manage clamp capacities while minimizing risks.

FAQ

1. What is the most common formula for calculating scaffolding clamp load capacity?

The most common formula is:

SWL=Scaffold’s Weight Capacity/(Maximum Intended Load + Scaffold Weight)×Safety Factor

This ensures that the safe working load accounts for all variables affecting clamp performance.

2. How do environmental conditions affect scaffolding clamp capacity?

Environmental factors like wind loads can exert lateral forces on clamps while rain or snow increases platform weight due to water accumulation or ice formation.

3. Can different types of scaffolding clamps be used interchangeably?

No, each type of clamp has specific applications and load capacities. Mixing incompatible clamps can compromise structural integrity.

4. What are some tools available for calculating scaffolding clamp capacities?

Online calculators like SkyCiv's Scaffolding Calculator provide detailed results based on input geometry, material properties, and design loads[2].

5. How often should scaffolding clamps be inspected?

Scaffolding clamps should be inspected before each use, after assembly or modifications, and at regular intervals during prolonged use[1].

Citations:

[1] https://www.safetyvideos.com/Understanding-the-Load-Capacity-of-Scaffolding

[2] https://skyciv.com/quick-calculators/scaffolding-calculator/

[3] https://www.hunanworld.com/news/how-to-calculate-the-loading-capacity-of-scaffolding-20210324

[4] https://irp-cdn.multiscreensite.com/f357d3c7/files/uploaded/wijisoguguvexomiv.pdf

[5] https://www.youtube.com/watch?v=QLm93w_rf5I

[6] https://www.linkedin.com/pulse/basic-analysis-load-caculations-scaffolding-design-natverlal-t-jadav

[7] https://www.youtube.com/watch?v=OpWEOdwXMu4