Content Menu

● Introduction to H Frame Scaffolding

● Main Components of H Frame Scaffolding

● Step-by-Step Assembly Guide

>> Step 1: Prepare the Site

>> Step 2: Lay Out Components

>> Step 3: Position H Frames

>> Step 4: Install Cross Braces

>> Step 5: Add Horizontal Ledgers

>> Step 6: Install Platforms

>> Step 7: Secure Guardrails and Toe Boards

>> Step 8: Final Inspection

● Safety Considerations

● Common Mistakes to Avoid

● Applications of H Frame Scaffolding

● Benefits of Using H Frame Scaffolding

>> Safety First

>> Enhanced Stability

>> Space Efficiency

● Regulatory Compliance

● Training and Education

● Conclusion

● FAQ

>> 1. What are the main components of H frame scaffolding?

>> 2. How is H frame scaffolding assembled?

>> 3. What safety precautions should be taken when using H frame scaffolding?

>> 4. What are the common applications of H frame scaffolding?

>> 5. What materials are H frame scaffolding systems typically made of?

● Citations:

H frame scaffolding is a versatile and widely used system in construction and maintenance projects. It provides a stable platform for workers to perform tasks at elevated heights. This article will guide you through the process of making and assembling H frame scaffolding, highlighting its components, safety considerations, and applications.

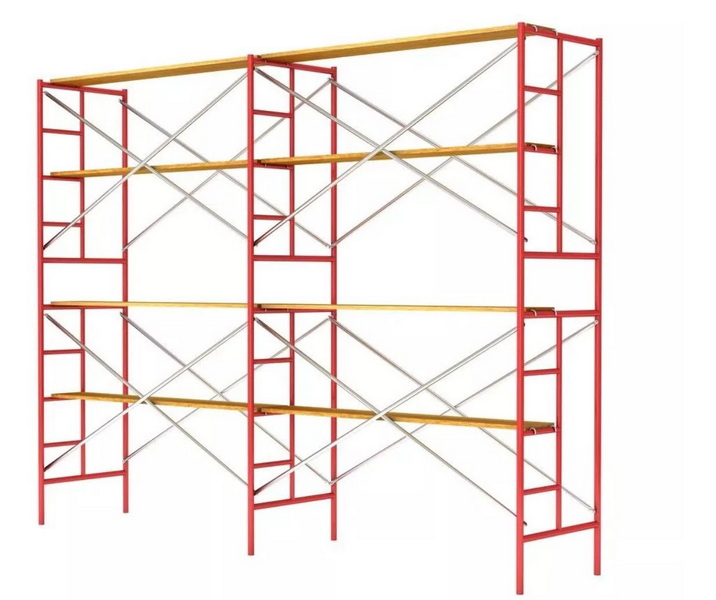

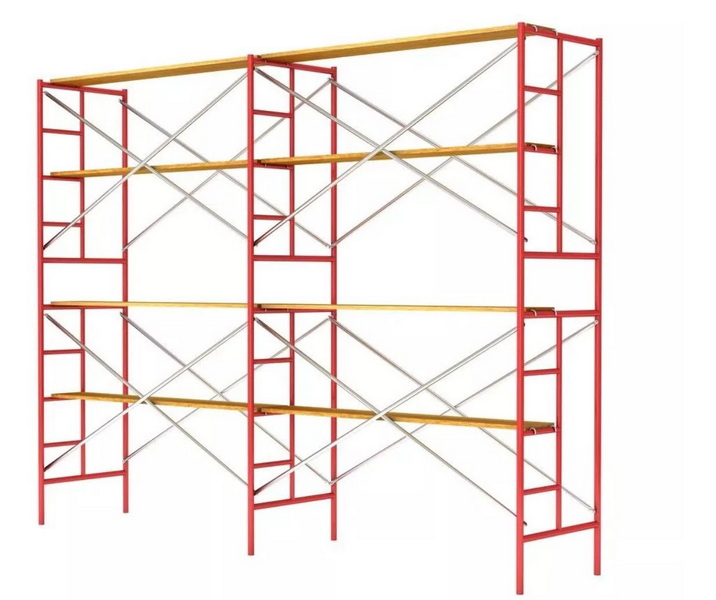

Introduction to H Frame Scaffolding

H frame scaffolding consists of vertical H-shaped frames, cross braces, and horizontal ledgers. These components interlock to form a rigid structure that supports workers and materials at various heights. The system is designed for fast and easy assembly, reducing labor costs and setup time.

Main Components of H Frame Scaffolding

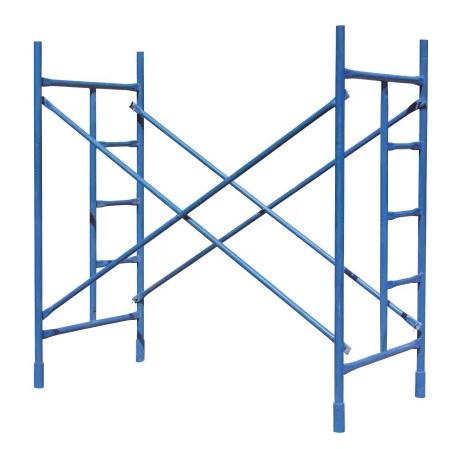

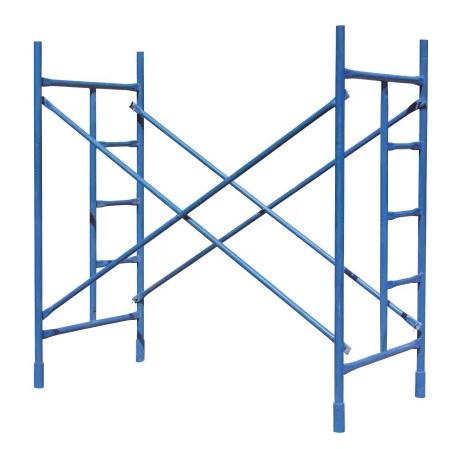

1. H Frames: The primary vertical structures that provide support and stability.

2. Cross Braces: Diagonal connectors that enhance rigidity and prevent movement.

3. Horizontal Ledgers: Support beams that help distribute weight evenly.

4. Base Plates: Positioned at the bottom to provide a stable foundation.

5. Wood Planks/Plywood Platforms: Used as walkways for workers to stand and operate safely.

6. Guardrails and Toe Boards: Added for worker safety to prevent falls and injuries.

7. Joint Pins and Couplers: Connect different scaffold sections securely.

Step-by-Step Assembly Guide

Step 1: Prepare the Site

Ensure the ground is level and free of obstacles. This is crucial for the stability of the scaffold.

Step 2: Lay Out Components

Arrange all the components, including H frames, cross bracing, single bracing, plan bracing, and tie bracing. Verify that every part is error-free and in excellent working order.

Step 3: Position H Frames

Stand the vertical H frames at the desired location. Ensure they are aligned and parallel to each other, with the broader part of the frames facing outward.

Step 4: Install Cross Braces

Erect the cross braces to connect the H frames, enhancing the structure's rigidity.

Step 5: Add Horizontal Ledgers

Install the horizontal ledgers to support the platforms.

Step 6: Install Platforms

Place the wood planks or plywood platforms on the ledgers for workers to stand on.

Step 7: Secure Guardrails and Toe Boards

Add guardrails and toe boards to prevent falls and injuries.

Step 8: Final Inspection

Inspect the entire structure for stability and ensure all components are securely locked in place.

Safety Considerations

Safety is paramount when assembling and using H frame scaffolding. Ensure that:

- All components are inspected for damage before use.

- The scaffold is properly tied to the building to prevent swaying.

- Guardrails and toe boards are securely installed.

- Workers wear appropriate safety gear, including harnesses and hard hats.

Common Mistakes to Avoid

When using H frame scaffolding, it's crucial to avoid common mistakes that can compromise safety:

- Poor Inspection Practices: Regular inspections are essential to identify signs of wear or damage in the scaffolding components. Neglecting routine inspections increases the risk of accidents due to compromised structural integrity[2].

- Incorrect Assembly Procedure: Ensure the ground is level and stable before assembly. Placing scaffolding on uneven or unstable ground can destabilize the entire structure, posing a severe risk to workers[2].

- Neglecting Fall Protection Measures: Falls from heights are a common cause of injuries. Neglecting fall protection measures, such as guardrails, toe boards, and personal fall arrest systems, significantly increases the risk of accidents[2].

Applications of H Frame Scaffolding

H frame scaffolding is versatile and can be used in various applications, including:

- Building Construction: Ideal for exterior and interior work.

- Industrial Maintenance: Suitable for repairs and maintenance in industrial settings.

- Bridge Repairs: Provides a stable platform for workers to access high areas.

- Painting and Plastering: Ensures stability for workers handling surface treatments.

- Shipbuilding and Event Staging: Offers temporary yet strong support structures where needed[1][5].

Benefits of Using H Frame Scaffolding

Safety First

The sturdy foundation of H frame scaffolding, characterized by vertical frames and strategically positioned braces, forms a reliable base. This robust structure not only ensures that the scaffold can bear substantial loads but also provides a secure platform for workers to perform their tasks[5].

Enhanced Stability

Compared to alternative scaffolding systems, H frame scaffolding offers superior stability. The "H" shape configuration provides a balanced distribution of weight, preventing wobbling or swaying during use. This stability is especially critical in dynamic work environments or in scenarios where multiple workers are operating simultaneously[5].

Space Efficiency

Another significant advantage of H frame scaffolding is its space efficiency. The vertical frames can be positioned closely together, allowing for optimal use of limited work areas. This feature is invaluable in congested construction sites or projects with spatial constraints[5].

Regulatory Compliance

H frame scaffolding must comply with industry safety regulations such as OSHA, ANSI, and EN standards. These regulations define critical aspects, including load-bearing capacity, material specifications, and worker protection requirements[1]. Regular inspections should be conducted to identify potential hazards such as structural wear, loose connections, or damage to key components. Trained personnel must oversee the installation and maintenance process, ensuring that all safety protocols are strictly followed[1].

Training and Education

Proper worker training is essential for preventing falls and other accidents. Employees should be familiar with safe assembly procedures, weight limits, and emergency protocols. Additionally, the use of personal protective equipment (PPE), such as harnesses, helmets, and non-slip footwear, is crucial for minimizing risks[1].

Conclusion

H frame scaffolding is a reliable and efficient system for construction and maintenance projects. Its ease of assembly, durability, and safety features make it a preferred choice for many applications. By following the assembly guidelines and adhering to safety protocols, workers can ensure a safe and productive work environment.

FAQ

1. What are the main components of H frame scaffolding?

The main components include H frames, cross braces, horizontal ledgers, base plates, platforms, guardrails, and joint pins.

2. How is H frame scaffolding assembled?

Assembly involves positioning H frames, installing cross braces, adding horizontal ledgers, placing platforms, securing guardrails, and ensuring all components are locked in place.

3. What safety precautions should be taken when using H frame scaffolding?

Ensure all components are inspected for damage, the scaffold is properly tied to the building, guardrails and toe boards are installed, and workers wear safety gear.

4. What are the common applications of H frame scaffolding?

Common applications include building construction, industrial maintenance, bridge repairs, painting and plastering, and event staging.

5. What materials are H frame scaffolding systems typically made of?

H frame scaffolding systems are typically made from high-quality steel or aluminum, ensuring durability and meeting safety standards.

Citations:

[1] https://apacsafety.com/comprehensive-guide-to-h-frame-scaffolding/

[2] https://msafegroup.com/expert-insights-common-mistakes-to-avoid-when-using-h-frame-scaffolding/

[3] https://msafegroup.com/h-frame-scaffolding-systems-a-detailed-manual/

[4] http://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.451

[5] https://primesteeltech.co.in/h-frame-scaffolding-systems-a-comprehensive-guide.html

[6] http://www.osha.gov/etools/scaffolding/supported/frame

[7] https://synergyaccessandscaffolding.com.au/wp-content/uploads/2017/10/H-FRAME-ASSEMBLY-MANUAL-1-watermark.pdf

[8] https://www.labour.gov.hk/eng/public/os/B/mss.pdf