Content Menu

● Introduction to Aluminum Planks

● Benefits of Aluminum Planks

● Installation of Aluminum Planks for Decking

● Installation of Aluminum Planks for Scaffolding

● Types of Aluminum Planks

● Safety Considerations

● Maintenance of Aluminum Planks

● Environmental Impact

● Comparison with Other Materials

● Customization and Compatibility

● Conclusion

● FAQ

>> 1. What are the benefits of using aluminum planks for decking and scaffolding?

>> 2. How do I properly install aluminum planks for decking?

>> 3. What safety considerations should I take when using aluminum planks in scaffolding?

>> 4. How often should I inspect aluminum planks?

>> 5. Are aluminum planks suitable for heavy-duty applications?

● Citations:

Aluminum planks are widely used in both decking and scaffolding applications due to their lightweight, durable, and corrosion-resistant properties. Proper installation of aluminum planks is crucial to ensure safety and structural integrity. In this article, we will explore the steps and considerations for installing aluminum planks in decking and scaffolding systems.

Introduction to Aluminum Planks

Aluminum planks are made from high-quality aluminum alloys, offering superior strength-to-weight ratios compared to traditional materials like wood and steel. They are ideal for various construction projects, including residential and commercial decking, as well as scaffolding systems for maintenance and repair work.

Benefits of Aluminum Planks

1. Lightweight and Easy to Handle: Aluminum planks are significantly lighter than steel, reducing the risk of accidents during handling and installation.

2. Durability: Aluminum planks are designed to withstand harsh conditions, including moisture and chemicals, ensuring a longer lifespan.

3. Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents corrosion, making it ideal for use in various environments.

4. Cost-Effectiveness: Although aluminum planks have a higher initial cost, their long lifespan and low maintenance requirements make them cost-effective in the long run.

5. Versatility: Aluminum planks can be used in a variety of decking and scaffolding systems, providing flexibility for different applications.

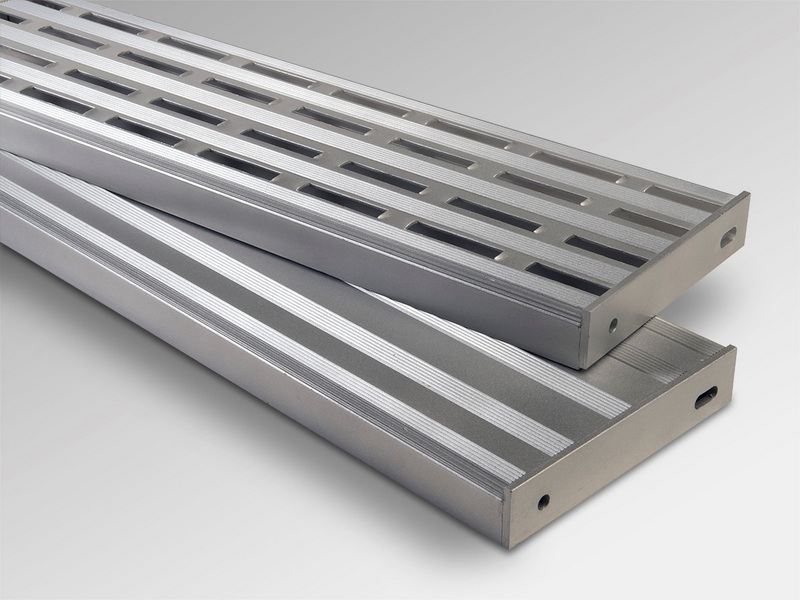

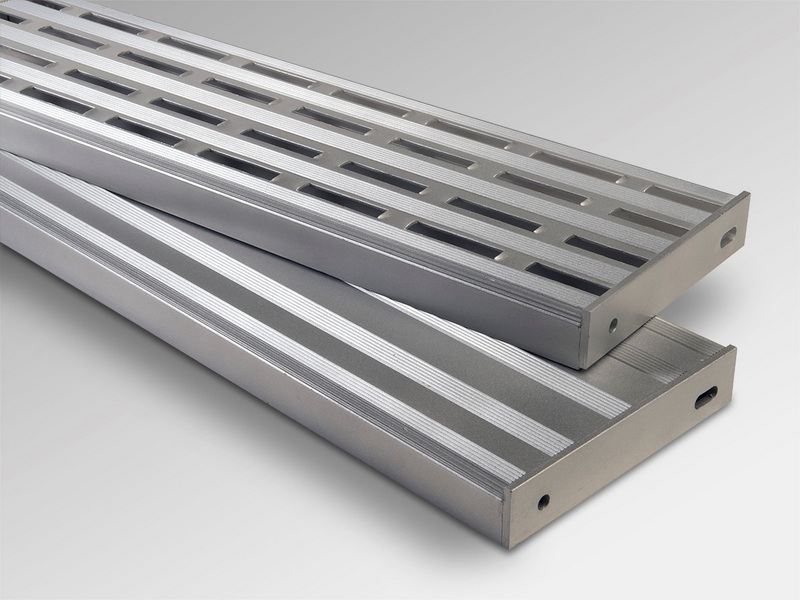

Installation of Aluminum Planks for Decking

When installing aluminum planks for decking, follow these steps:

1. Prepare the Site: Ensure the ground is level and secure. Install pedestals or joists according to the manufacturer's guidelines.

2. Install Starter Clips: Fix starter clips into the central channel along the ends of each joist, where the first aluminum decking board will be installed.

3. Place the First Board: Insert the male flange of the aluminum decking board into the female starter strip at an angle and snap it into place.

4. Secure the Board: Fasten the board to the joist using self-drilling screws and washers provided.

5. Repeat the Process: Continue installing boards, ensuring a 5mm expansion gap between the decking and any walls or solid structures.

Installation of Aluminum Planks for Scaffolding

For scaffolding applications, aluminum planks are used to create a stable platform for workers. Here's how to install them:

1. Erect the Scaffolding Frame: Follow the manufacturer's instructions to set up the scaffolding frame, ensuring it is level and secure.

2. Place the Aluminum Plank: Position the aluminum plank onto the scaffolding frame, ensuring it is centered and secure.

3. Secure the Plank: Use appropriate fasteners or hooks to secure the plank to the scaffolding frame.

4. Install Guardrails: Attach guardrails to the scaffolding posts to ensure safety.

5. Conduct Safety Checks: Regularly inspect the scaffolding and aluminum planks to ensure they are secure and in good condition.

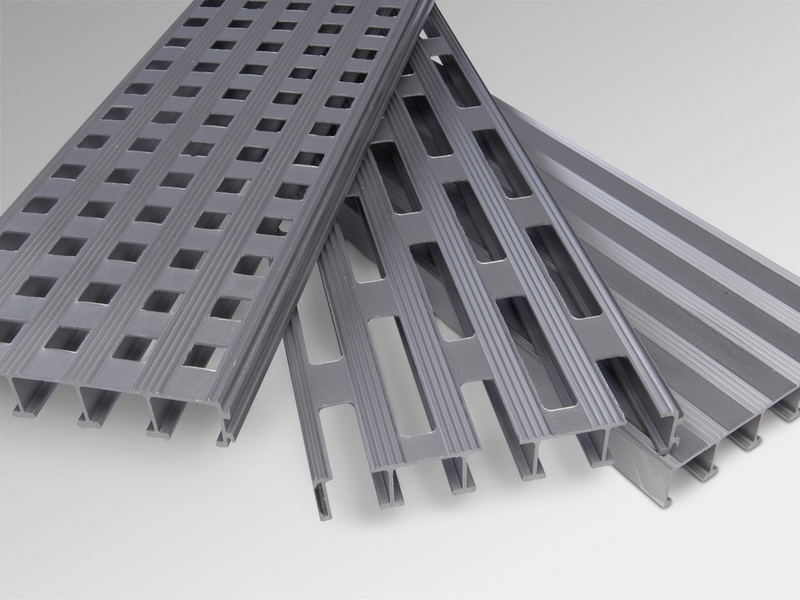

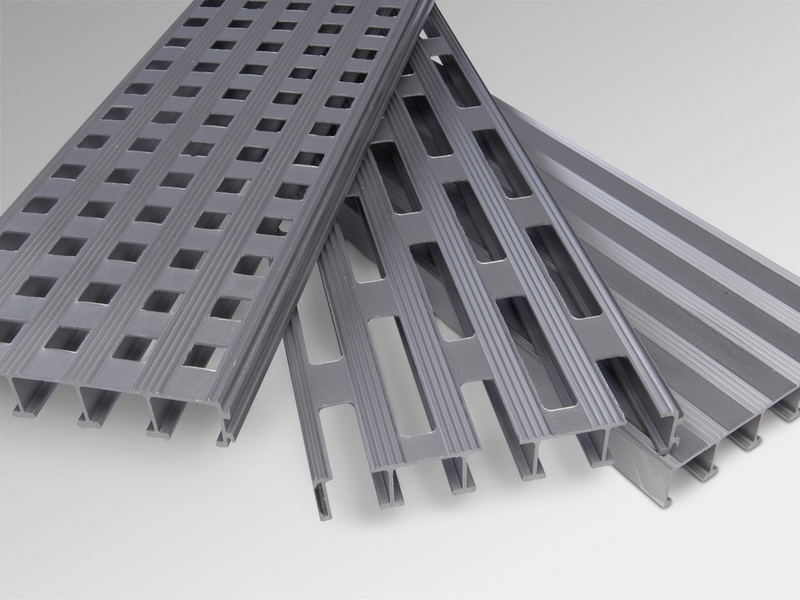

Types of Aluminum Planks

There are several types of aluminum planks available, each designed for specific applications:

1. All Aluminum Planks: Made entirely of aluminum, these planks offer superior strength and durability.

2. Aluminum and Plywood Planks: These combine the strength of aluminum with the cost-effectiveness of plywood, providing a versatile solution for various applications.

3. Aluminum Planks with Trapdoor and Ladder: These planks are equipped with a trapdoor and ladder for convenient access and use in various scaffolding systems.

4. Aluminum and Plywood Planks with Trapdoor and Ladder: These composite planks feature an aluminum frame and a plywood surface, designed with a trapdoor and ladder for easy access.

Safety Considerations

Safety is paramount when installing and using aluminum planks:

- Regular Inspections: Conduct regular inspections to ensure all components are secure and in good condition.

- Proper Training: Ensure that personnel installing and using scaffolding are properly trained and certified.

- Load Capacity: Always adhere to the recommended load capacity of the aluminum planks and scaffolding system.

Maintenance of Aluminum Planks

Aluminum planks require minimal maintenance due to their corrosion-resistant properties. However, regular cleaning can help maintain their appearance and ensure safety:

- Cleaning: Aluminum planks can be easily cleaned with water and mild detergents.

- Inspection: Regularly inspect for any signs of wear or damage.

Environmental Impact

Aluminum planks contribute to sustainability by reducing waste and environmental impact:

- Recyclable: Aluminum is fully recyclable, reducing waste and conserving natural resources.

- Long Lifespan: The durability of aluminum planks means fewer replacements are needed, further reducing waste.

Comparison with Other Materials

Aluminum planks offer several advantages over traditional materials like wood and steel:

- Lightweight: Aluminum planks are significantly lighter than steel and easier to handle than wood.

- Durability: Aluminum planks are more resistant to corrosion and wear compared to steel and wood.

- Cost-Effectiveness: Although initially more expensive, aluminum planks are cost-effective due to their long lifespan and low maintenance.

Customization and Compatibility

Aluminum planks can be customized to fit specific project needs:

- Custom Lengths and Widths: Many manufacturers offer customization options for aluminum planks to ensure they fit perfectly with your scaffolding or decking system.

- Compatibility with Scaffolding Systems: Aluminum planks are compatible with various scaffolding systems, including ringlock and frame scaffolding.

Conclusion

Aluminum planks are versatile and essential components for both decking and scaffolding systems. Their lightweight, durable, and corrosion-resistant properties make them ideal for various applications. Proper installation and regular maintenance are crucial to ensure safety and structural integrity. By following the guidelines outlined in this article, you can effectively install aluminum planks for your decking or scaffolding project.

FAQ

1. What are the benefits of using aluminum planks for decking and scaffolding?

Aluminum planks are lightweight, durable, corrosion-resistant, and cost-effective, making them ideal for various construction projects.

2. How do I properly install aluminum planks for decking?

Install aluminum decking boards by fixing starter clips, inserting the male flange into the starter strip at an angle, and securing with self-drilling screws.

3. What safety considerations should I take when using aluminum planks in scaffolding?

Ensure regular inspections, proper training, and adherence to load capacity recommendations to ensure safety.

4. How often should I inspect aluminum planks?

Regular inspections are crucial to ensure all components are secure and in good condition, ideally before each use.

5. Are aluminum planks suitable for heavy-duty applications?

Yes, aluminum planks can be used for heavy-duty applications, but ensure they meet the required load capacity and are used with appropriate decking or scaffolding systems.

Citations:

[1] https://www.usascaffolding.com/product/aluminum-scaffold-boards-planks-decks/

[2] http://lastdeck.com/aluminum-decking-S200-installation-guide.PDF

[3] https://scaffoldingrentalandsales.com/aluminum/plywood-scaffold-planks/

[4] https://www.mydek.com/wp-content/uploads/2024/05/9.-MyDek-Aluminium-Decking-Installation-Guide_0524.pdf

[5] https://aaitscaffold.com/products/scaffolding-planks/aluminum-plank/

[6] https://www.cladcodecking.co.uk/media/pdf/Aluminium_Decking_Installation_Guide.pdf

[7] https://www.wm-scaffold.com/aluminum-planks.html

[8] https://builddeck.co.uk/wp-content/uploads/2020/05/Builddeck-Aluminium-Installation-Guide-B.pdf

[9] https://falconladder.com/scaffold-decks-1/