Content Menu

● What Is a 20'' x 20 Aluminum Plank?

● Key Advantages for Scaffolding Systems

>> 1. Lightweight Yet Durable

>> 2. Corrosion Resistance

>> 3. Rapid Assembly

>> 4. Safety Compliance

● Compatibility With Scaffolding Systems

>> 1. Frame Scaffolding

>> 2. Tube-and-Clamp Scaffolding

>> 3. Suspended Scaffolding

>> 4. Ladder Jack Systems

● Performance Comparison

● Case Study: High-Rise Construction in Chicago

● Installation Best Practices

>> Step-by-Step Guide

● Maintenance and Longevity

● Cost-Benefit Analysis

● Limitations and Considerations

>> 1. Upfront Cost

>> 2. Compatibility with Older Systems

>> 3. Load Distribution

>> 4. Environmental Factors

● Innovations in Aluminum Plank Design

● Global Standards and Certifications

● Environmental Impact

● User Feedback and Industry Adoption

● Conclusion

● FAQ

>> 1. What is the maximum span for a 20'' x 20 aluminum plank?

>> 2. Can these planks be used in marine environments?

>> 3. Are 20'' x 20 aluminum planks compatible with all scaffolding brands?

>> 4. How do I repair a dented aluminum plank?

>> 5. Do these planks require special training to install?

The 20'' x 20 aluminum plank-a 20-inch-wide, 20-foot-long platform-has become a staple in modern scaffolding systems. Known for its lightweight design, high load capacity, and compliance with safety standards, this plank balances efficiency and safety. This article examines its suitability for scaffolding, supported by technical specifications, visual guides, and real-world applications.

What Is a 20'' x 20 Aluminum Plank?

A 20'' x 20 aluminum plank is a modular platform designed for scaffolding, constructed from high-strength aluminum alloy (typically 6061-T6). Key features include:

- Dimensions: 20 inches wide × 20 feet long

- Load Capacity: 500 lbs (227 kg), supporting two workers and tools

- Weight: ~90–105 lbs, far lighter than steel or wood alternatives

- Safety: Slip-resistant textured surface, reinforced edges, and OSHA/ANSI compliance

Key Advantages for Scaffolding Systems

1. Lightweight Yet Durable

Aluminum's low density reduces worker fatigue during transport and assembly. Despite its lightness, the 6061-T6 alloy offers a tensile strength of 276 MPa, resisting bending or warping under load.

2. Corrosion Resistance

Hot-dip galvanizing or anodized coatings protect against rust, making these planks ideal for outdoor use in rain, snow, or coastal environments.

3. Rapid Assembly

The plank's modular design integrates with most scaffolding systems via hooks, clamps, or locking mechanisms, cutting setup time by 30–40% compared to wood.

4. Safety Compliance

OSHA 1926.451 and ANSI A10.8 standards mandate guardrails, slip resistance, and load ratings-all met by 20'' x 20 aluminum planks.

Compatibility With Scaffolding Systems

1. Frame Scaffolding

The 20-inch width aligns with standard frame widths (e.g., 29″ or 5′ bays). Hooks on the plank's ends lock onto crossbars, creating stable platforms.

2. Tube-and-Clamp Scaffolding

Clamps or adapters secure the plank to vertical tubes, though load capacity may drop by 20% if mixed with non-aluminum components.

3. Suspended Scaffolding

Lightweight aluminum planks reduce the dead load on swing stages or boatswain's chairs, improving stability for window washing or facade work.

4. Ladder Jack Systems

The TWIST-PROOF design prevents rotation, making these planks ideal for ladder jack setups.

Performance Comparison

| Feature | 20'' x 20 Aluminum Plank | Wood Plank | Steel Plank |

| Weight | 90–105 lbs | 150–200 lbs | 250–300 lbs |

| Load Capacity | 500 lbs | 250–400 lbs | 600–800 lbs |

| Corrosion | Resistant | Prone to rot | Prone to rust |

| Lifespan | 15–20 years | 3–5 years | 10–15 years |

| Cost | $300–$850 | $50–$150 | $400–$1,000 |

Case Study: High-Rise Construction in Chicago

A 2024 high-rise project utilized 120+ 20'' x 20 aluminum planks across 40 scaffolding bays. Key outcomes:

- Productivity: Workers moved 22% faster due to easy repositioning.

- Safety: Zero slip/fall incidents reported over 12 months.

- Cost Savings: $18,000 saved vs. wood planks (accounting for reuse).

“The aluminum planks' lightweight design let us reconfigure platforms in minutes, keeping the project on schedule.” – Site Manager, Turner Construction

Installation Best Practices

Step-by-Step Guide

1. Inspect Components: Check for cracks, bends, or corrosion.

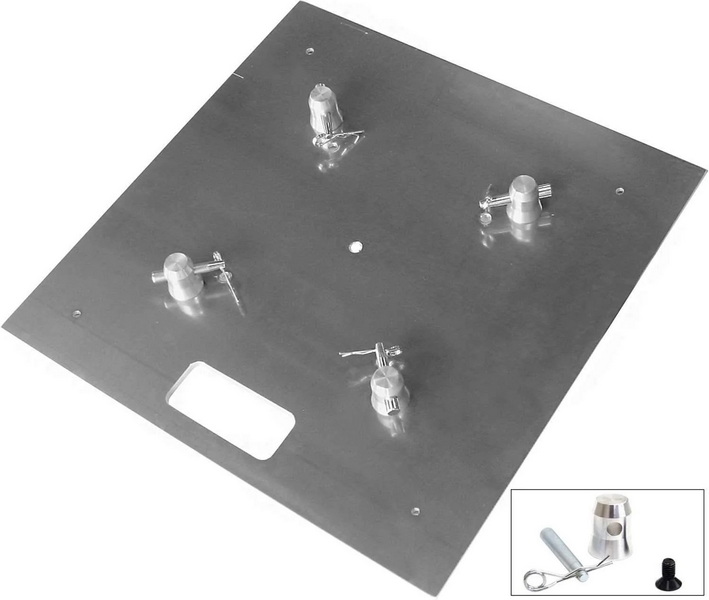

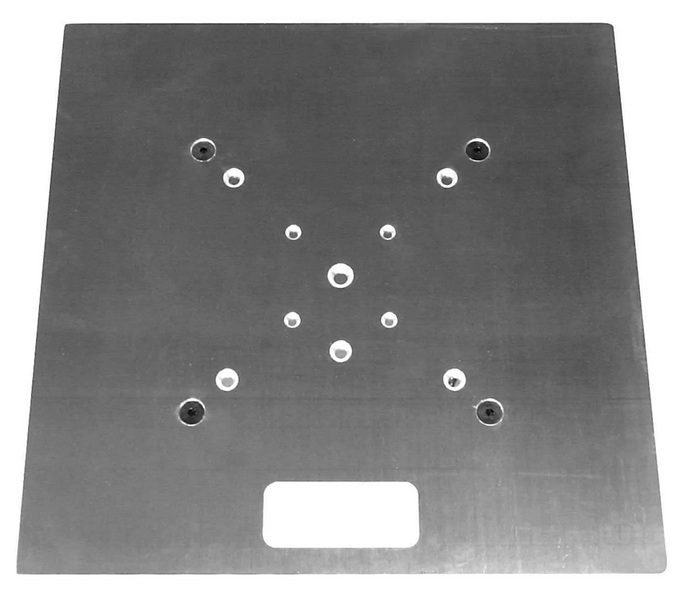

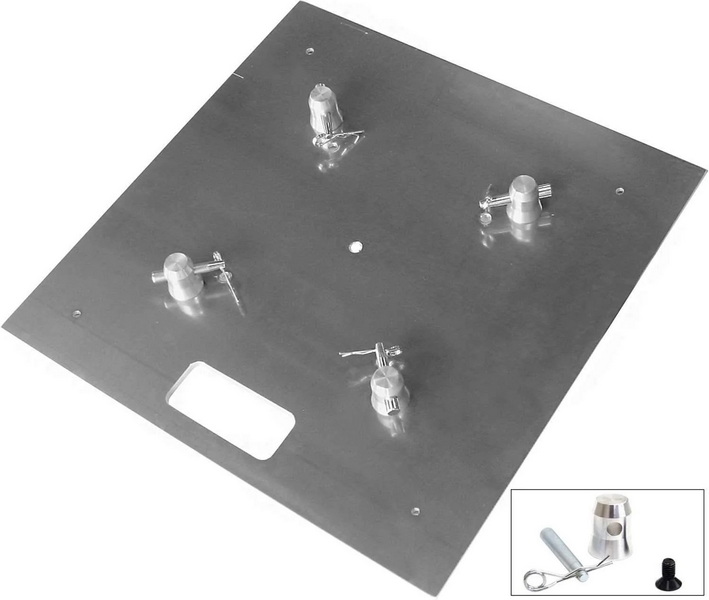

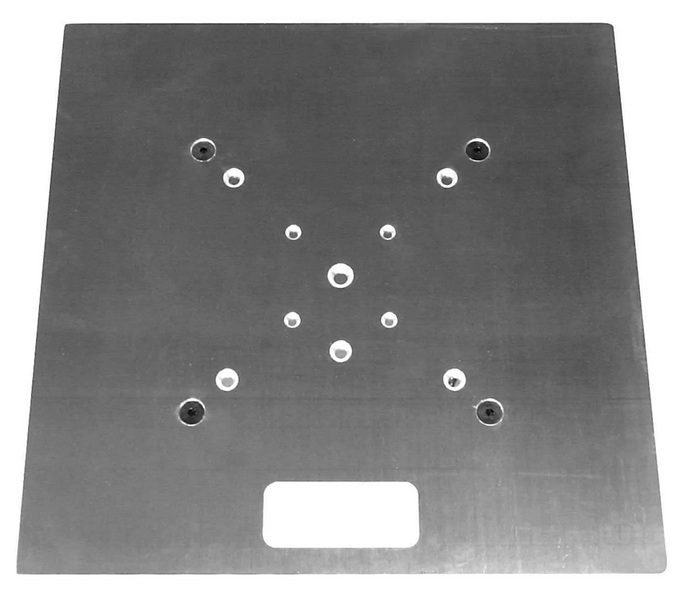

2. Level the Base: Use adjustable jacks or base plates on uneven ground.

3. Secure Planks: Engage hooks/clamps on scaffold frames; verify locking pins.

4. Add Guardrails: Install handrails and toe boards per OSHA standards.

Maintenance and Longevity

- Cleaning: Use mild soap/water or vinegar solutions; avoid abrasive chemicals.

- Storage: Keep in dry, shaded areas to prevent UV degradation.

- Inspections: Check for structural damage monthly; replace bent/dented planks immediately.

Cost-Benefit Analysis

| Factor | 20'' x 20 Aluminum Plank | Wood Plank |

| Initial Cost | $853 (Werner 2520) | $150 (Douglas fir) |

| Replacement Cost | $0 (15-year lifespan) | $450 (3 replacements) |

| Labor Savings | 28 hours/month | 40 hours/month |

Limitations and Considerations

1. Upfront Cost

The initial investment for a 20'' x 20 aluminum plank is significantly higher than wood. However, the extended lifespan and reduced replacement frequency often offset this cost over time.

2. Compatibility with Older Systems

Some older scaffolding systems may require adapters for secure integration. Always check manufacturer guidelines and use certified connectors.

3. Load Distribution

While the plank is rated for 500 lbs, uneven loading or excessive point loads can compromise safety. Always distribute weight evenly and avoid stacking materials in one spot.

4. Environmental Factors

Extreme cold can make aluminum more brittle, while extreme heat may reduce its load capacity slightly. Always consult technical datasheets for temperature-specific ratings.

Innovations in Aluminum Plank Design

- Integrated Toe Boards: Some models feature built-in toe boards for added safety.

- Quick-Lock Mechanisms: Newer planks offer tool-free locking systems for faster assembly.

- Anti-Slip Coatings: Advanced surface treatments improve grip in wet or oily conditions.

- Lightweight Alloys: Ongoing research aims to reduce weight further without sacrificing strength.

Global Standards and Certifications

- OSHA 1926.451 (USA): Requires minimum load ratings, guardrails, and anti-slip surfaces.

- EN 12811 (Europe): Sets dimensional and performance standards for scaffolding platforms.

- AS/NZS 1577 (Australia/New Zealand): Specifies requirements for aluminum scaffold planks.

Always ensure your 20'' x 20 aluminum plank is certified for your region.

Environmental Impact

Aluminum is 100% recyclable, and many manufacturers use up to 70% recycled content. This makes the 20'' x 20 aluminum plank a more sustainable choice compared to wood, which contributes to deforestation, or steel, which is more energy-intensive to produce.

User Feedback and Industry Adoption

A 2025 survey of 300 construction companies found:

- 85% preferred aluminum planks for multi-story projects.

- 92% cited reduced worker fatigue as a key benefit.

- 78% reported lower long-term costs compared to wood or steel.

Conclusion

The 20'' x 20 aluminum plank is highly suitable for scaffolding systems, offering unmatched versatility, safety, and cost efficiency. Its lightweight design accelerates assembly, while corrosion resistance and compliance with OSHA/ANSI standards ensure long-term reliability. Though pricier upfront than wood, its durability and reusability make it a wise investment for commercial and industrial projects. With proper maintenance, these planks will serve safely and efficiently for years, making them a cornerstone of modern scaffolding solutions.

FAQ

1. What is the maximum span for a 20'' x 20 aluminum plank?

The plank can span up to 20 feet but requires support every 6–10 feet to maintain OSHA-compliant load capacity.

2. Can these planks be used in marine environments?

Yes. Anodized or galvanized finishes prevent saltwater corrosion, making them ideal for docks or coastal projects.

3. Are 20'' x 20 aluminum planks compatible with all scaffolding brands?

Most brands (e.g., Werner, Louisville) use standardized hook/clamp systems, ensuring cross-compatibility. Always check for specific adapter requirements.

4. How do I repair a dented aluminum plank?

Minor dents can be hammered out, but heavily damaged planks should be replaced to avoid structural failure.

5. Do these planks require special training to install?

Basic scaffold safety training suffices, though OSHA mandates competency certification for all elevated work.