Content Menu

● Introduction to Scaffolding Couplers

>> Fixed Couplers

>> Swivel Couplers

● Advantages of Fixed Coupler Scaffolding

● Disadvantages of Fixed Coupler Scaffolding

● Advantages of Swivel Couplers

● Disadvantages of Swivel Couplers

● Applications of Fixed Coupler and Swivel Couplers

● Safety Considerations

● Maintenance and Inspection

● Environmental Factors

● Technological Advancements

● Training and Certification

● Conclusion

● FAQ

>> 1. What are the primary types of scaffolding couplers?

>> 2. What are the advantages of fixed coupler scaffolding?

>> 3. What are the disadvantages of swivel couplers?

>> 4. In what scenarios are swivel couplers preferred?

>> 5. How important is safety in scaffolding assembly?

● Citations:

Scaffolding is an essential component in construction, renovation, and maintenance projects, providing a safe and stable platform for workers to perform their tasks. Among the various types of scaffolding systems, tube and coupler scaffolding stands out for its versatility and robustness. This article will delve into the comparison between fixed coupler scaffolding and swivel couplers, exploring their advantages, disadvantages, and applications.

Introduction to Scaffolding Couplers

Scaffolding couplers are critical components that connect scaffolding tubes, ensuring the structural integrity and stability of the scaffold. There are several types of couplers, each designed for specific purposes and load capacities. The two primary types we will focus on are fixed couplers and swivel couplers.

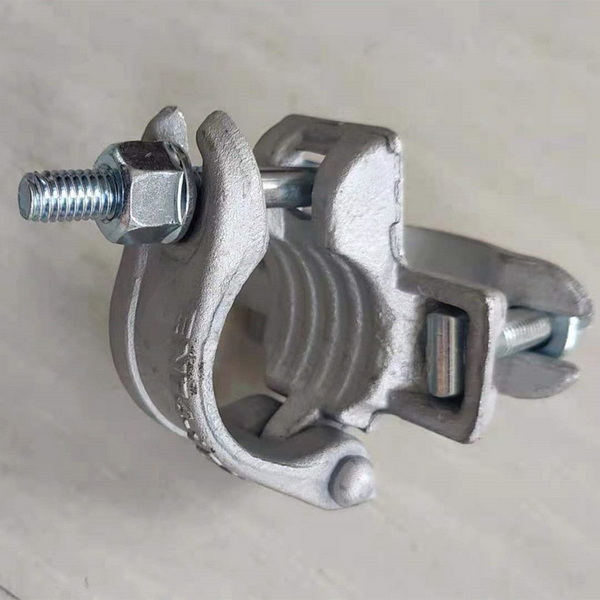

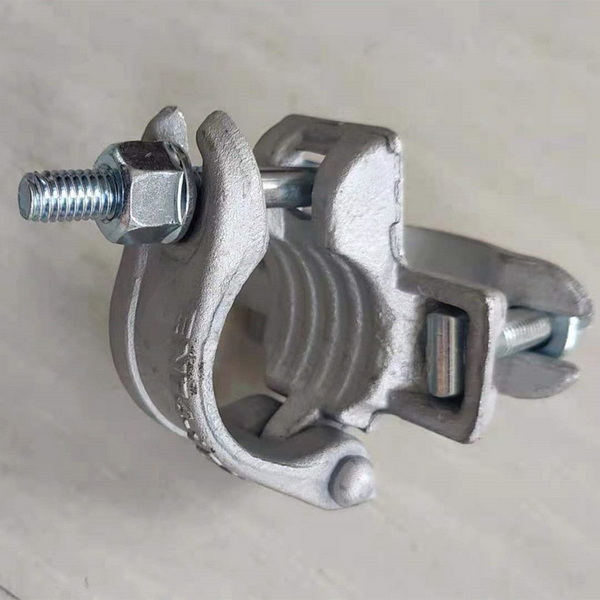

Fixed Couplers

Fixed couplers, such as right-angle couplers, are used to connect tubes at a fixed angle, typically 90 degrees. These couplers are essential for creating the basic framework of scaffolding structures, providing strong and stable joints that can support significant loads.

Swivel Couplers

Swivel couplers, on the other hand, offer flexibility by allowing tubes to be connected at various angles. This feature is particularly useful for complex scaffolding setups where diagonal bracing or irregular structures are required.

Advantages of Fixed Coupler Scaffolding

Fixed coupler scaffolding, particularly when using right-angle couplers, offers several advantages:

1. Structural Stability: Fixed couplers provide a strong and stable connection, which is crucial for load-bearing applications.

2. Simplicity in Assembly: Although the overall assembly of tube and coupler scaffolding can be complex, fixed couplers themselves are straightforward to use once the scaffold's design is established.

3. Cost-Effectiveness: While the initial setup might be more expensive due to labor costs, fixed couplers are generally less expensive than swivel couplers.

Disadvantages of Fixed Coupler Scaffolding

Despite its advantages, fixed coupler scaffolding also has some drawbacks:

1. Limited Flexibility: Fixed couplers do not allow for adjustments in angle once they are set up, which can limit their use in projects requiring frequent changes in scaffolding configuration.

2. Higher Labor Costs for Setup: Although the couplers themselves are simple, the overall setup of tube and coupler scaffolding requires skilled labor, which can increase costs.

Advantages of Swivel Couplers

Swivel couplers offer several benefits that make them ideal for certain applications:

1. Flexibility: Swivel couplers allow for connections at various angles, making them perfect for complex or irregular structures.

2. Adaptability: They can be easily adjusted to accommodate changes in scaffolding design or unexpected site conditions.

Disadvantages of Swivel Couplers

While swivel couplers provide flexibility, they also have some disadvantages:

1. Higher Cost: Swivel couplers are generally more expensive than fixed couplers due to their complex design.

2. Potential for Misalignment: If not properly secured, swivel couplers can lead to misalignment issues, affecting the stability of the scaffold.

Applications of Fixed Coupler and Swivel Couplers

Both fixed coupler scaffolding and swivel couplers have specific applications based on their characteristics:

- Fixed Coupler Scaffolding: Ideal for projects requiring strong, stable structures with minimal need for angle adjustments, such as building facades or large-scale construction projects.

- Swivel Couplers: Suitable for projects with complex geometries or those requiring frequent adjustments, such as stage setups or renovation projects with irregular structures.

Safety Considerations

Regardless of whether fixed coupler scaffolding or swivel couplers are used, safety is paramount. Improper assembly or misuse can lead to instability and accidents. It is crucial to follow safety guidelines and ensure that scaffolding is erected by trained professionals.

Maintenance and Inspection

Regular maintenance and inspection are critical for ensuring the longevity and safety of scaffolding. This includes checking for wear and tear on couplers, ensuring all connections are secure, and replacing any damaged components promptly.

Environmental Factors

Environmental factors such as weather conditions can significantly impact scaffolding stability. Wind, rain, and extreme temperatures can affect the structural integrity of scaffolding, making it essential to design and secure scaffolding with these factors in mind.

Technological Advancements

Recent technological advancements have led to the development of more durable and versatile scaffolding materials and designs. For instance, advanced materials like aluminum and fiberglass offer lighter yet stronger alternatives to traditional steel scaffolding.

Training and Certification

Proper training and certification are essential for scaffolding professionals. Ensuring that workers understand how to safely assemble, use, and dismantle scaffolding is critical for preventing accidents and ensuring compliance with safety regulations.

Conclusion

In conclusion, the choice between fixed coupler scaffolding and swivel couplers depends on the specific needs of the project. Fixed coupler scaffolding offers stability and cost-effectiveness but lacks flexibility, while swivel couplers provide adaptability but at a higher cost and with potential stability risks if not properly used. Understanding the advantages and disadvantages of each type is essential for selecting the most appropriate scaffolding solution.

FAQ

1. What are the primary types of scaffolding couplers?

The primary types include right-angle couplers, swivel couplers, sleeve couplers, putlog couplers, and beam couplers, each serving distinct roles in scaffolding assembly and load distribution.

2. What are the advantages of fixed coupler scaffolding?

Fixed coupler scaffolding provides structural stability, simplicity in assembly once the design is established, and cost-effectiveness compared to swivel couplers.

3. What are the disadvantages of swivel couplers?

Swivel couplers are generally more expensive than fixed couplers and can lead to misalignment issues if not properly secured, affecting scaffold stability.

4. In what scenarios are swivel couplers preferred?

Swivel couplers are preferred in projects requiring flexibility and adaptability, such as complex structures or setups where frequent adjustments are necessary.

5. How important is safety in scaffolding assembly?

Safety is paramount in scaffolding assembly. Improperly assembled scaffolding can lead to accidents, so it is crucial to follow safety guidelines and ensure that scaffolding is erected by trained professionals.

Citations:

[1] https://in.kcxbridge.com/resources/tube-and-coupler-scaffolds-a-complete-guide.html

[2] https://shelterrc.com/scaffolding-couplers-types-a-comprehensive-guide/

[3] https://patents.google.com/patent/WO2003091512A1/zh

[4] https://safetyeducations.com/tube-and-coupler-scaffolds/

[5] https://www.adtoscaffold.com/new/how_many_kinds_of_scaffolding_coupler_are_there.html

[6] https://www.bbc.com/learningenglish/chinese/features/q-and-a/ep-200318

[7] https://biblus.accasoftware.com/en/scaffolding-types-uses-and-features/

[8] https://apacsafety.com/the-ultimate-guide-of-scaffolding-couplers/

[9] https://scaffoldtype.com/scaffold-tube-couplers/

[10] https://www.wm-scaffold.com/scaffolding-coupler.html

[11] https://scaffoldtype.com/scaffolding-coupler/