Content Menu

● What Is Layher System Scaffolding?

● Key Features and Engineering Innovations

● Core Components and Modular Design

● Suitability for Different Project Types

>> Construction (Commercial & Residential)

>> Industrial & Infrastructure

>> Events & Special Structures

>> Complex or Confined Spaces

● Safety, Compliance, and Certifications

● Productivity and Cost Efficiency

● Real-World Project Examples

● Accessories and Expansion Options

● Assembly Process and Training

● Maintenance, Durability, and Sustainability

● Digital Planning, Support, and Global Network

● Environmental Impact and Sustainability Initiatives

● Conclusion

● FAQ

>> 1. What makes Layher system scaffolding different from traditional scaffolding?

>> 2. Is Layher system scaffolding suitable for residential projects?

>> 3. How does Layher system scaffolding improve safety on site?

>> 4. What is the lifespan and maintenance requirement of Layher system scaffolding?

>> 5. Can Layher system scaffolding be used for complex or irregular structures?

Choosing the right scaffolding system is a critical decision for any construction, industrial, or maintenance project. Layher system scaffolding, particularly the renowned Layher Allround® and SpeedyScaf® systems, has become the gold standard for modular scaffolding worldwide. But is Layher system scaffolding suitable for your project? This comprehensive guide will help you answer that question by exploring its features, benefits, applications, technical details, and real-world performance.

What Is Layher System Scaffolding?

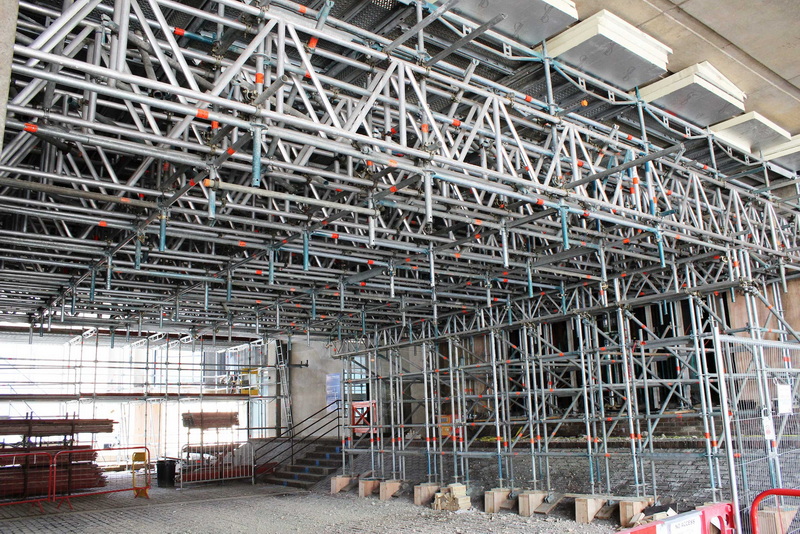

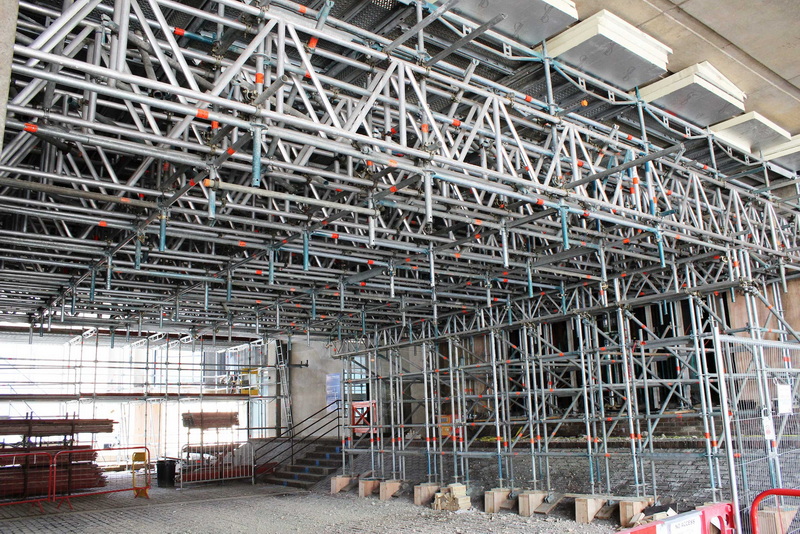

Layher system scaffolding is a modular, prefabricated scaffolding solution engineered in Germany and used globally across construction, industrial, and event sectors. The heart of the Layher system is its Allround® rosette connector, which allows up to eight connections at a single node and enables fast, bolt-free assembly at a variety of angles. Layher system scaffolding is available in steel and aluminum, offering lightweight strength, rapid assembly, and unmatched adaptability for even the most complex structures.

Key Features and Engineering Innovations

- Versatility: The modular design supports right-angled, obtuse, and acute connections, making it adaptable to irregular layouts, complex architecture, and challenging site conditions.

- Speed: Bolt-free, AutoLock assembly means Layher system scaffolding can be erected and dismantled much faster than traditional tube-and-coupler systems.

- Strength and Safety: High-grade steel and aluminum components, precision manufacturing, and built-in safety features provide robust load-bearing capacity and compliance with global standards.

- Reduced Weight: Layher's lightweight components are up to 40% lighter than some alternatives, making handling and transport easier while reducing labor fatigue.

- Fewer Components: The system is engineered with fewer parts, reducing complexity, storage, and risk of missing pieces on site.

- Weather and Corrosion Resistance: Hot-dip galvanized steel and aluminum resist corrosion, making Layher system scaffolding suitable for outdoor and harsh environments.

Core Components and Modular Design

Layher system scaffolding includes:

- Rosette Connector: The core innovation, allowing multiple ledgers and braces to connect at various angles.

- Standards (Vertical Tubes): With rosettes at 50 cm intervals for flexible connections.

- Ledgers and Braces: Horizontal and diagonal members for structural stability.

- Platforms/Decks: Non-slip, high-strength surfaces for safe working.

- Base Plates and Adjustable Jacks: For secure footing and leveling on uneven ground.

- Guardrails, Toe Boards, and Safety Accessories: Integrated safety at every level.

- Stair Towers, Bridging Beams, and Weather Protection: Expandable with Layher's full accessory range.

Suitability for Different Project Types

Construction (Commercial & Residential)

Layher system scaffolding is ideal for new builds, renovations, and facade work. Its modularity means it can wrap around complex architectural features, fit tight urban sites, and adapt to sloped or uneven terrain. For residential projects, Layher's quick assembly and minimal disruption are especially valuable.

Industrial & Infrastructure

From power stations and chemical plants to bridges and tunnels, Layher system scaffolding excels in demanding environments. Its load capacity, adaptability, and compliance with strict safety standards make it the system of choice for industrial maintenance, shutdowns, and infrastructure upgrades.

Events & Special Structures

Layher system scaffolding is used for stages, grandstands, temporary roofs, and public access structures. Its modularity and accessory range allow for creative, safe, and code-compliant solutions for events and temporary installations.

Complex or Confined Spaces

Layher system scaffolding can be configured for birdcage scaffolds, suspended platforms, and access in tight or irregular spaces. Its lightweight, easy-to-handle components are ideal for interior renovations and maintenance in confined areas.

Safety, Compliance, and Certifications

Layher system scaffolding is engineered for safety from the ground up:

- AutoLock and Self-Locking Connections: Reduce assembly errors and enhance stability.

- Guardrails and Toe Boards: Required on all open sides for fall protection.

- Compliance: Certified to EN 12810, EN 12811, OSHA, and other international standards.

- Protect System: Modular weather and debris protection for safe, clean worksites up to 90 meters high.

- Inspection and Maintenance: Designed for easy inspection, with robust components that resist wear and damage.

Productivity and Cost Efficiency

- Faster Assembly: Layher system scaffolding can be erected and dismantled up to five times faster than traditional scaffolding, saving labor and reducing downtime.

- Reduced Labor Costs: Lightweight components and fewer parts mean smaller crews can work more efficiently.

- Long-Term Value: Durability, high resale value, and minimal maintenance deliver a lower total cost of ownership over the system's long lifespan.

- Optimized Logistics: Standardized packaging and modular design simplify transport and storage.

Real-World Project Examples

- High-Rise Construction: Layher system scaffolding enabled rapid, safe facade access for skyscraper projects, reducing overall build time and labor costs.

- Industrial Maintenance: Power plants and refineries rely on Layher system scaffolding for shutdowns and repairs, where time and safety are critical.

- Residential Developments: Builders use Layher system scaffolding for multi-home projects, benefiting from its adaptability and speed.

- Event Structures: Layher's modular system supports stages, grandstands, and temporary roofs at major sporting and cultural events.

Accessories and Expansion Options

Layher system scaffolding offers a comprehensive range of accessories:

- Protective Enclosures: Weatherproof panels and roofs for all-season work.

- Bridging and FlexBeam Systems: For wide-span access and heavy-duty support.

- Rolling Towers and SoloTower: Mobile solutions for interior or maintenance work.

- STAR Frame and SpeedyScaf: For even faster assembly and lighter weight in compatible applications.

- Custom Solutions: Modular components enable unique configurations for special project requirements.

Assembly Process and Training

Layher system scaffolding is designed for intuitive, safe assembly:

1. Site Survey: Assess ground conditions, access, and hazards.

2. Base Setup: Install base plates and standards, ensuring level and plumb alignment.

3. Frame Construction: Attach ledgers and braces to the rosette connector using a hammer—no bolts required.

4. Platform and Guardrail Installation: Secure platforms, guardrails, and toe boards at each level.

5. Inspection: Verify all connections and safety features before use.

Maintenance, Durability, and Sustainability

- Corrosion Resistance: Hot-dip galvanized steel and aluminum components are built to withstand harsh weather and industrial environments.

- Long Service Life: Layher system scaffolding typically lasts over 10 years with proper maintenance, far outlasting many traditional systems.

- Easy Maintenance: Fewer moving parts and robust design reduce the need for repairs.

- Sustainability: Reusable components, minimal waste, and efficient logistics contribute to a lower environmental footprint.

Digital Planning, Support, and Global Network

Layher system scaffolding is supported by advanced digital tools and a worldwide network:

- LayPLAN CAD: A powerful 3D planning tool that integrates with AutoCAD, enabling detailed scaffold design, collision checks, and automatic generation of parts lists.

- Material Management: Digital systems streamline logistics, ensuring the right components are delivered on time for efficient assembly.

- Global Training and Support: Layher offers certified training programs, technical support, and on-site consultation in over 140 countries, ensuring you have expert guidance at every stage.

- Documentation and Manuals: Comprehensive technical documentation, safety manuals, and assembly guides are available in multiple languages for global accessibility.

Environmental Impact and Sustainability Initiatives

Layher system scaffolding is designed with sustainability in mind:

- Reusability: Modular components can be reused across dozens of projects, reducing material waste.

- Recyclable Materials: Steel and aluminum parts are fully recyclable at the end of their long service life.

- Efficient Transport: Lightweight, stackable components reduce transport emissions and storage space.

- Green Building Support: Using Layher system scaffolding can help projects achieve green certifications by minimizing site impact and supporting responsible material use.

Conclusion

Layher system scaffolding is suitable for a vast range of projects, from small residential renovations to large-scale industrial and infrastructure works. Its modular design, rapid assembly, robust safety features, and proven performance make it the preferred choice for contractors, builders, and event organizers worldwide. Whether your project demands speed, flexibility, safety, or long-term value, Layher system scaffolding delivers on every front. By investing in Layher, you gain not only a scaffolding solution but also the support of a global leader in engineering, innovation, and customer service.

FAQ

1. What makes Layher system scaffolding different from traditional scaffolding?

Layher system scaffolding uses a patented rosette connector for bolt-free, rapid assembly at multiple angles, offering superior flexibility, speed, and safety compared to traditional tube-and-coupler scaffolding.

2. Is Layher system scaffolding suitable for residential projects?

Yes. Its modularity, adaptability to complex shapes, and quick assembly make Layher system scaffolding ideal for residential construction, renovations, and multi-home developments.

3. How does Layher system scaffolding improve safety on site?

Layher system scaffolding features AutoLock connections, integrated guardrails and toe boards, and is certified to international safety standards. Accessories like the Protect System and AGS guardrail further enhance safety.

4. What is the lifespan and maintenance requirement of Layher system scaffolding?

With proper use and routine inspection, Layher system scaffolding components can last over a decade. Hot-dip galvanized steel and aluminum resist corrosion, and the system requires minimal maintenance compared to traditional scaffolding.

5. Can Layher system scaffolding be used for complex or irregular structures?

Absolutely. The modular design and rosette connector allow Layher system scaffolding to adapt to complex geometries, confined spaces, and challenging layouts—making it suitable for virtually any project.