Content Menu

● Understanding Pin Lock Scaffolding System

● Key Features of Pin Lock Scaffolding System

● Benefits of Using Pin Lock Scaffolding System

>> Versatility and Adaptability

>> Ease of Assembly

>> High Load-Bearing Capacity

>> Enhanced Safety

>> Cost-Effectiveness

● Applications of Pin Lock Scaffolding System

● Pin Lock vs. Ring Lock Scaffolding

● Pin Lock vs. Cuplock Scaffolding

● Considerations When Choosing Pin Lock Scaffolding System

● Best Practices for Using Pin Lock Scaffolding System

● Conclusion

● FAQ

>> 1. What is a pin lock scaffolding system?

>> 2. What are the key advantages of using a pin lock scaffolding system?

>> 3. How does pin lock scaffolding compare to ring lock scaffolding?

>> 4. What types of projects are best suited for pin lock scaffolding?

>> 5. What should be considered when choosing a pin lock scaffolding system?

● Citations:

Choosing the right scaffolding system is a critical decision for any construction project. The selected system directly impacts safety, efficiency, and cost-effectiveness. Among the various options available, the pin lock scaffolding system offers unique advantages that make it a suitable choice for certain project requirements. This article explores the benefits, applications, and considerations of the pin lock scaffolding system to help you determine if it's the right fit for your specific project needs.

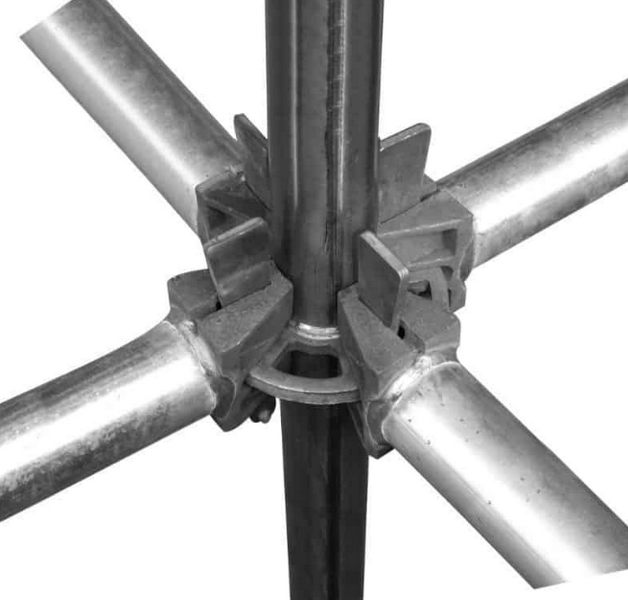

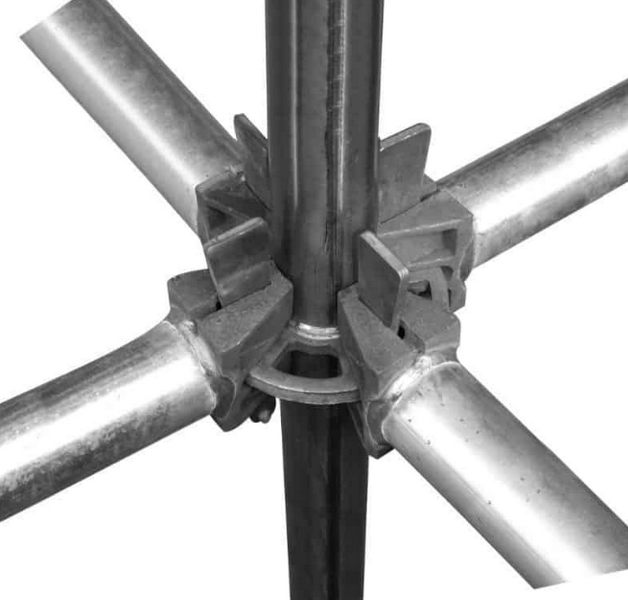

Understanding Pin Lock Scaffolding System

The pin lock scaffolding system is a modular scaffolding type that uses pins to connect vertical and horizontal components, creating a rigid and secure structure[7]. These pins lock into keyhole slots, ensuring a stable connection[7]. Known for its versatility, the pin lock scaffolding system is designed to be constructed to fit almost anywhere and for almost any purpose[3].

Key Features of Pin Lock Scaffolding System

-Pin Connections: The system relies on pins to connect horizontal and vertical components[7].

-Keyhole Slots: Pins lock into keyhole slots for secure and rigid structure[7].

-Versatility: Can be designed and constructed to fit virtually anywhere[3].

-Structural Integrity: Offers robust stability for various construction environments[10].

-Ease of Use: Simplified assembly makes it suitable for projects with tight timelines[10].

Benefits of Using Pin Lock Scaffolding System

Versatility and Adaptability

One of the most significant advantages of the pin lock scaffolding system is its versatility. This system can be easily adapted to fit complex geometries, making it suitable for various industrial structures and equipment[7]. The ability to build complex scaffolding configurations, such as bridges, towers, and customized access platforms, makes the pin lock scaffolding system a preferred choice for projects with unique structural requirements[7].

Ease of Assembly

The pin lock scaffolding system is known for its simple and quick setup, making it a favorite for projects with tight timelines[10]. The straightforward assembly process reduces the time and labor required, leading to increased efficiency on the construction site[9]. Workers do not waste time searching for and attaching multiple loose parts; the interlocking frames and platforms go together quickly, saving costs[9].

High Load-Bearing Capacity

The pin lock scaffolding system is ideal for supporting heavy loads, making it suitable for industrial construction and maintenance of large equipment[7]. The robust design ensures that the scaffold can handle the intended loads without compromising safety, providing a stable and secure working platform for workers[1].

Enhanced Safety

The pin lock scaffolding system offers enhanced safety features that contribute to a secure working environment. The interlocking components prevent unstable or uneven platforms, reducing the risk of accidents[9]. Proper installation and secured scaffolding pins contribute to the overall safety of the scaffold structure, preventing accidental disassembly or collapse[1].

Cost-Effectiveness

While the initial cost of a pin lock scaffolding system may be comparable to other systems, the long-term cost savings can be substantial. The faster installation times, reduced labor costs, and reusability of components make the pin lock scaffolding system a cost-effective choice for many projects[2][9].

Applications of Pin Lock Scaffolding System

-Industrial Construction: Suitable for supporting heavy loads and providing access to elevated work areas in plants and refineries[7].

-Bridge Construction: Adaptable for building complex scaffolding configurations required for bridge construction[7].

-Tower Construction: Ideal for constructing stable and secure towers for various purposes[7].

-Customized Access Platforms: Can be easily configured to create customized access platforms for unique project requirements[7].

-Shipyards: Used quite a bit in shipyards[11].

Pin Lock vs. Ring Lock Scaffolding

Pin lock and ring lock are both system scaffoldings, but they have key differences. Ringlock scaffolding utilizes a rosette-type connector that is rigid and versatile[5]. Pin lock, on the other hand, typically facilitates simpler, more linear structures and is preferred for projects requiring quick setup[10]. Ringlock offers a higher degree of flexibility to lock different numbers of angles and to align exactly 45° / 90° using grooves[2]. A disadvantage of ring lock is the number of components (nuts and bolts) that must be maintained[5].

Pin Lock vs. Cuplock Scaffolding

Pin lock and cuplock scaffolding are both modular systems, but they differ in their connection methods. Cuplock uses metal cups to lock beams and hold standards and ledgers together[5]. It is lightweight, easily installed for small projects, and does not require fasteners and small parts that must be maintained[5]. Cuplock is generally faster to assemble and disassemble, while pin lock may offer more flexibility for complex geometries and has a higher load capacity[7].

Considerations When Choosing Pin Lock Scaffolding System

-Project Complexity: For straightforward construction projects that require quick setup and repetitive use, pin lock is ideal[10].

-Load Requirements: If the project involves heavy loads, the robust design of pin lock makes it a suitable choice[7].

-Timeline: Pin lock's simplified assembly processes make it a favorite among projects with tight timelines[10].

-Budget: Evaluate the initial cost and long-term savings to determine if pin lock fits within the project budget[9].

-Training: Ensure that workers are properly trained in the correct assembly and disassembly techniques for pin lock scaffolding[7].

Best Practices for Using Pin Lock Scaffolding System

1. Regular Inspections: Conduct regular inspections before, during, and after each use of the scaffold to identify any potential issues with stability, integrity, or safety[1].

2. Proper Training: Ensure that all personnel involved in erecting, dismantling, or using scaffolding are adequately trained in safety protocols and assembly techniques[7].

3. Adhere to Regulations: Follow local regulations and standards regarding scaffolding design, assembly, use, and dismantling[7].

4. Use of Safety Equipment: All workers using scaffolding should be equipped with appropriate personal protective equipment (PPE), including hard hats, safety glasses, and fall protection harnesses[9].

5. Secure Connections: Ensure that all connections between scaffolding components are securely fastened using appropriate pins and fasteners[1].

6. Load Limits: Adhere to the scaffold's load limits and avoid overloading the structure[1].

7. Weather Precautions: Take appropriate precautions during adverse weather conditions, such as high winds or heavy rain[1].

Conclusion

The pin lock scaffolding system offers a range of benefits that make it a suitable choice for various construction projects. Its versatility, ease of assembly, high load-bearing capacity, and enhanced safety features contribute to a more efficient and secure working environment. By carefully considering the project's specific requirements and following best practices for assembly and use, construction companies can maximize the advantages of the pin lock scaffolding system.

FAQ

1. What is a pin lock scaffolding system?

A pin lock scaffolding system is a modular scaffolding type that uses pins to connect vertical and horizontal components, creating a rigid and secure structure[7].

2. What are the key advantages of using a pin lock scaffolding system?

The key advantages include versatility, ease of assembly, high load-bearing capacity, enhanced safety, and cost-effectiveness[7][10][9].

3. How does pin lock scaffolding compare to ring lock scaffolding?

Pin lock is typically used for simpler, more linear structures, while ring lock is more versatile for complex geometries. Ringlock uses a rosette connector, while pin lock uses pins in keyhole slots[5][10].

4. What types of projects are best suited for pin lock scaffolding?

Pin lock is best suited for industrial construction, bridge construction, tower construction, and customized access platforms[7].

5. What should be considered when choosing a pin lock scaffolding system?

Considerations include project complexity, load requirements, timeline, budget, and training[10][9][7].

Citations:

[1] https://dss.net/what-are-scaffold-coupling-pins-and-its-uses/

[2] https://www.zh-scaffolding.com/news/five-advantages-of-the-ringlock-scaffold.html

[3] https://www.majorscaffold.com/services/pin-lock-system/

[4] https://jumplyscaffolding.com/pin-lock-scaffold/

[5] https://www.scaffoldingsolutions.com/articles/what-is-the-best-system-scaffolding/

[6] https://scaffoldexpress.com/products/pin-ring-safety-vertical-for-hanging-ring-system

[7] https://rusindustrial.com/industrial/scaffolding/

[8] https://apacscaffold.com/5-types-of-scaffolding-materials/

[9] https://dss.net/top-5-benefits-of-ring-lock-scaffolding-systems/

[10] https://scafotech.com/understanding-scaffold-systems-pin-lock-scaffold-ringlock-scaffolding-allround-scaffolding-and-multidirectional-scaffolding/

[11] https://www.reddit.com/r/engineering/comments/1374iwe/pin_lock_scaffold_systems_pull_testing/

[12] https://www.totalcontec.com/6-types-of-system-scaffolding-and-their-uses/