Content Menu

● Introduction to Ringlock and Frame Scaffolding

>> What is Ringlock Scaffolding?

>> What is Frame Scaffolding?

● Structural Design and Components

>> Ringlock Scaffolding Components

>> Frame Scaffolding Components

● Assembly and Disassembly

>> Ringlock Scaffolding Assembly

>> Frame Scaffolding Assembly

● Load Capacity and Stability

>> Ringlock Scaffolding Load Capacity

>> Frame Scaffolding Load Capacity

● Adaptability and Application

>> Ringlock Scaffolding Adaptability

>> Frame Scaffolding Adaptability

● Cost Considerations

● Safety Features

● Detailed Comparison Table

● Advantages and Limitations of Ringlock Scaffolding

>> Advantages

>> Limitations

● Advantages and Limitations of Frame Scaffolding

>> Advantages

>> Limitations

● Conclusion

● FAQ

>> 1. What is the main difference between Ringlock scaffolding and frame scaffolding?

>> 2. Which scaffolding system is faster to assemble?

>> 3. Can Ringlock scaffolding be used for complex structures?

>> 4. Is frame scaffolding more cost-effective?

>> 5. Which scaffolding system offers better load-bearing capacity?

Scaffolding is an indispensable part of the construction industry, providing safe and stable platforms for workers to perform tasks at height. Among the many scaffolding systems available, Ringlock scaffolding and frame scaffolding are two of the most widely used and recognized types. Each has its own unique features, advantages, and limitations, making them suitable for different project requirements.

Introduction to Ringlock and Frame Scaffolding

What is Ringlock Scaffolding?

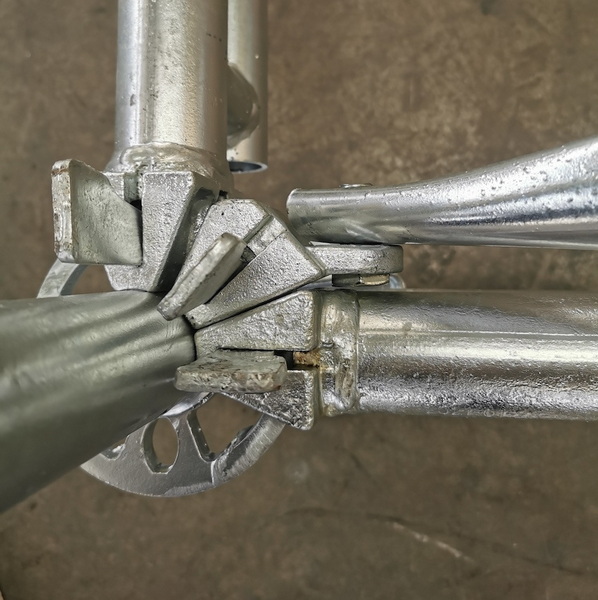

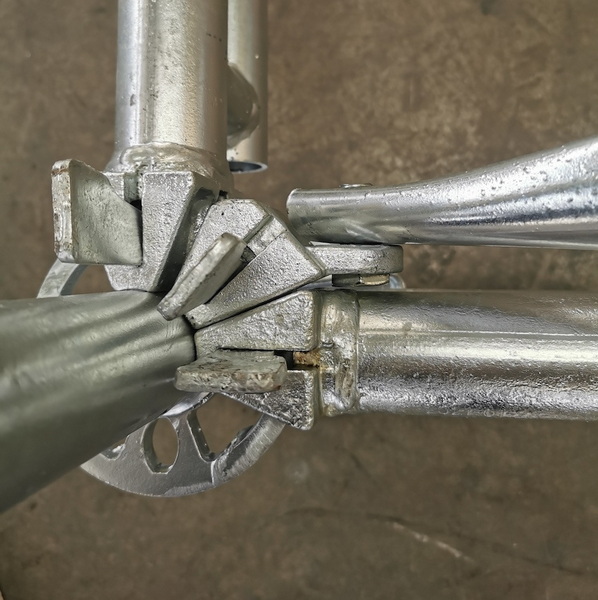

Ringlock scaffolding is a type of modular scaffolding system characterized by its unique rosette or ring connector. This system allows for quick and secure connections between vertical standards and horizontal ledgers or braces. The rosette features multiple holes at fixed intervals, enabling connections at various angles, which enhances flexibility and adaptability.

Ringlock scaffolding is widely praised for its:

- Versatility in complex geometries

- High load-bearing capacity

- Fast assembly and disassembly

- Modular design that supports scalability and customization

What is Frame Scaffolding?

Frame scaffolding, also known as H-frame scaffolding, is a traditional scaffolding system made up of prefabricated welded frames connected by cross braces. The frames are typically rectangular and stacked vertically to reach the desired height. Frame scaffolding is popular for its simplicity and cost-effectiveness, especially in straightforward, rectangular construction projects.

Frame scaffolding is known for:

- Ease of assembly for simple structures

- Cost efficiency

- Lighter horizontal and diagonal components

- Common use in residential and low-rise commercial construction

Structural Design and Components

Ringlock Scaffolding Components

- Vertical Standards: Steel tubes with welded rosettes (rings) at regular intervals (usually every 500mm).

- Horizontal Ledgers: Tubes connected to the rosettes using wedge locks.

- Diagonal Braces: Provide stability, connected similarly via the rosette system.

- Base Jacks: Adjustable supports for leveling.

- Decking and Platforms: Modular planks or metal decks fit onto the scaffold structure.

The rosette connector is the hallmark of Ringlock scaffolding, enabling connections at multiple angles (up to 8 directions), which allows for complex configurations.

Frame Scaffolding Components

- Prefabricated Frames: Welded rectangular steel frames, usually 2 meters tall and 0.9 meters wide.

- Cross Braces: Diagonal braces attached to frames for stability.

- Base Plates or Screw Jacks: For leveling on uneven ground.

- Platforms: Usually wooden or metal planks placed on horizontal ledgers.

Frame scaffolding's components are simpler, with frames acting as the main vertical and horizontal supports.

Assembly and Disassembly

Ringlock Scaffolding Assembly

Ringlock scaffolding assembly is faster and more efficient due to its modular design and unique locking mechanism:

- The rosette system allows for quick insertion and locking of ledgers and braces without the need for bolts or nuts.

- Assembly requires minimal tools, often just a hammer to secure wedges.

- The modular system enables easy expansion or modification on-site.

- Disassembly mirrors assembly, allowing for rapid teardown and reuse.

Frame Scaffolding Assembly

- Frame scaffolding involves stacking prefabricated frames vertically and securing them with cross braces.

- Assembly is straightforward but can be slower for taller or more complex structures.

- Bolts or pins are used to secure braces and frames, requiring more tools and labor.

- Disassembly requires unfastening multiple components, which can be time-consuming.

Load Capacity and Stability

Ringlock Scaffolding Load Capacity

- Ringlock scaffolding boasts a high load-bearing capacity due to its robust steel standards and secure rosette connections.

- The system supports heavy materials and equipment, suitable for industrial and commercial construction.

- Its design provides superior stability even on uneven or irregular surfaces.

- The ability to connect braces at multiple angles enhances rigidity.

Frame Scaffolding Load Capacity

- Frame scaffolding is designed for light to moderate loads, making it suitable for smaller-scale projects.

- The welded frame structure provides reasonable stability but is less adaptable to heavy loads or irregular geometries.

- Stability depends heavily on proper bracing and securing of frames.

Adaptability and Application

Ringlock Scaffolding Adaptability

- The modular rosette design allows Ringlock scaffolding to adapt to complex building shapes, including curved facades, circular tanks, and irregular structures.

- It is ideal for large-scale commercial, industrial, and infrastructure projects requiring flexibility.

- The system is also suitable for hanging scaffolds and suspended platforms due to its high load capacity and secure connections.

- Transport and storage are efficient because components are linear tubes and smaller accessories.

Frame Scaffolding Adaptability

- Frame scaffolding is best suited for simple, rectangular structures like residential buildings and general maintenance work.

- It is less flexible in adapting to complex shapes or curved surfaces.

- The system is commonly used for low-rise construction due to its ease of assembly and cost-effectiveness.

- Frames are bulky and take up more space during transport and storage.

Cost Considerations

- Frame scaffolding is generally more cost-effective upfront, especially for simple projects with repetitive, rectangular layouts.

- Ringlock scaffolding involves higher initial investment but offers better long-term value through faster assembly, adaptability, and reusability.

- Labor costs for Ringlock scaffolding are often lower due to quicker erection and dismantling.

- Maintenance and replacement costs are typically lower for Ringlock systems because of their modular and durable design.

Safety Features

- Ringlock scaffolding's rosette system provides secure locking points that reduce accidental disassembly risks.

- The system offers more tie-off points for worker safety harnesses, improving fall protection.

- Frame scaffolding relies on proper bracing and secure connections but has fewer integrated safety features.

- Both systems require adherence to safety standards and proper inspection to ensure worker safety.

Detailed Comparison Table

Feature | Ringlock Scaffolding | Frame Scaffolding |

Connection System | Rosette (ring) with wedge locks | Prefabricated welded frames with cross braces |

Assembly Speed | Fast, tool-light | Moderate, requires tools and labor |

Load Capacity | High, suitable for heavy-duty applications | Moderate, suitable for light to medium loads |

Adaptability | Highly adaptable to complex shapes | Best suited for simple, rectangular layouts |

Cost | Higher initial cost, lower labor cost | Lower initial cost, higher labor cost |

Safety Features | Multiple secure locking points, tie-offs | Basic safety, reliant on proper bracing |

Storage & Transport | Compact, modular components | Bulky, larger components |

Common Applications | Industrial, commercial, infrastructure projects | Residential, low-rise commercial |

Advantages and Limitations of Ringlock Scaffolding

Advantages

- Modular and flexible design: Easily adapts to complex structures.

- High load-bearing capacity: Suitable for heavy industrial use.

- Fast assembly and disassembly: Reduces labor costs and project timelines.

- Enhanced safety features: Multiple locking points and tie-offs for fall protection.

- Durability: Made from high-quality steel with corrosion-resistant finishes.

Limitations

- Higher upfront cost: Initial investment is more than frame scaffolding.

- Requires skilled labor: While assembly is faster, correct installation is critical.

- Component complexity: More parts to manage and maintain.

Advantages and Limitations of Frame Scaffolding

Advantages

- Cost-effective: Lower initial investment for simple projects.

- Simple design: Easy to understand and assemble for basic structures.

- Widely available: Commonly used and readily sourced worldwide.

- Lightweight components: Easier to handle for small-scale projects.

Limitations

- Limited adaptability: Not suitable for complex or curved structures.

- Lower load capacity: Not ideal for heavy industrial applications.

- Slower assembly for large projects: Requires more labor and tools.

- Bulkier components: More cumbersome to transport and store.

Conclusion

Both Ringlock scaffolding and frame scaffolding have their places in the construction industry, each offering distinct advantages. Frame scaffolding remains a reliable and cost-effective choice for straightforward, low-rise projects with simple geometries. However, Ringlock scaffolding stands out for its versatility, superior load capacity, faster assembly, and adaptability to complex structures. Its modular rosette system enables construction projects to progress efficiently, especially when dealing with irregular shapes or heavy-duty applications.

For projects demanding flexibility, safety, and long-term cost efficiency, Ringlock scaffolding is often the preferred solution. Understanding the key differences between these systems empowers project managers and contractors to select the most suitable scaffolding, optimizing safety, cost, and project timelines.

FAQ

1. What is the main difference between Ringlock scaffolding and frame scaffolding?

The main difference lies in their connection systems: Ringlock uses a rosette-based modular locking system allowing multi-angle connections, while frame scaffolding uses prefabricated welded frames connected by cross braces.

2. Which scaffolding system is faster to assemble?

Ringlock scaffolding generally allows faster assembly and disassembly due to its modular design and wedge locking mechanism, requiring fewer tools and less labor.

3. Can Ringlock scaffolding be used for complex structures?

Yes, Ringlock scaffolding is highly adaptable to complex geometries, including curved facades and irregular shapes, thanks to its multi-angle rosette connectors.

4. Is frame scaffolding more cost-effective?

Frame scaffolding tends to be more cost-effective for simple, rectangular, low-rise projects, but Ringlock scaffolding offers better long-term value for complex or heavy-duty projects.

5. Which scaffolding system offers better load-bearing capacity?

Ringlock scaffolding typically provides superior load-bearing capacity due to its robust design and secure locking mechanism, making it suitable for heavy materials and industrial applications.