Content Menu

● 1. Nanjing Tuopeng Construction Technology Co., Ltd

>> Company Overview

>> Product Range

>> Key Features

>> Manufacturing Capabilities

● 2. Foshan SAMZOON Sandwich Panel Manufacturing Co., Ltd

● 3. Xiamen Shengqian Steel Technology Co., Ltd

● 4. Yantai Asa Industrial and Trading Co., Ltd

● 5. Shanghai Sunnyda House Co., Ltd

● 6. BRDECO

● 7. Sinowa

● 8. Qingdao YMSandwich Panel Co., Ltd

● 9. Zhejiang Cosasteel Co., Ltd

● 10. Guangzhou Jet Scaffold & Formwork System Co., Ltd

● Additional Insights on Color Steel Sandwich Panel Manufacturing in China

>> Advanced Manufacturing Technologies

>> Environmental and Safety Compliance

>> OEM and ODM Services

>> Logistics and Export Capabilities

>> Market Trends and Innovations

● Conclusion

● FAQ

>> 1. What are the common core materials used in color steel sandwich panels?

>> 2. Can color steel sandwich panels be customized in size and color?

>> 3. What are the typical applications of color steel sandwich panels?

>> 4. How do manufacturers ensure the fire resistance of sandwich panels?

>> 5. What is the typical lead time for ordering color steel sandwich panels from China?

China's color steel sandwich panel industry has experienced remarkable growth in recent years, becoming a major supplier for global construction, prefab housing, industrial buildings, and commercial projects. These panels are highly regarded for their excellent insulation properties, fire resistance, lightweight structure, and aesthetic appeal. This article highlights the Top 10 Color Steel Sandwich Panel Manufacturers in China, with Nanjing Tuopeng Construction Technology Co., Ltd leading the list due to its comprehensive product range, advanced manufacturing technology, and strong OEM service capabilities.

1. Nanjing Tuopeng Construction Technology Co., Ltd

Company Overview

Nanjing Tuopeng Construction Technology Co., Ltd (TPCT) stands out as a top-tier manufacturer specializing in color steel sandwich panels, steel structures, and prefab houses. Based in Nanjing, Jiangsu Province, TPCT has accumulated over 20 years of experience supplying OEM services to international brand owners, wholesalers, contractors, and manufacturers. Their commitment to quality, innovation, and customer satisfaction has earned them a solid reputation worldwide.

Product Range

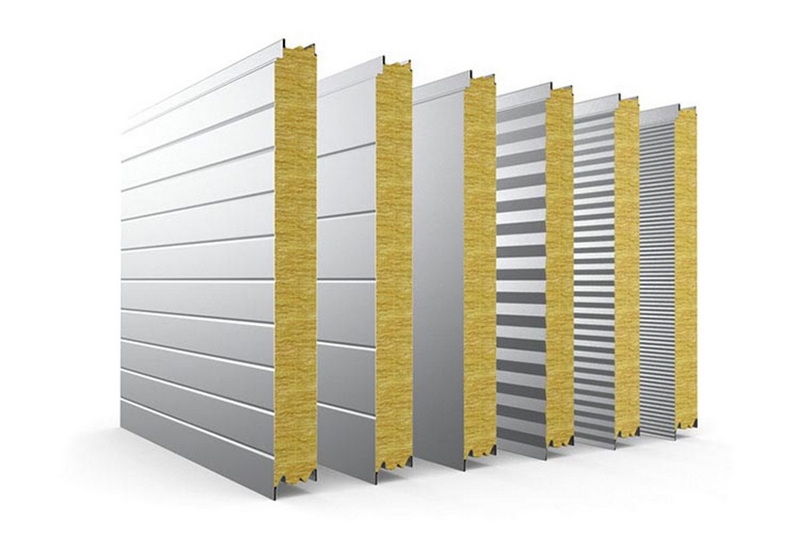

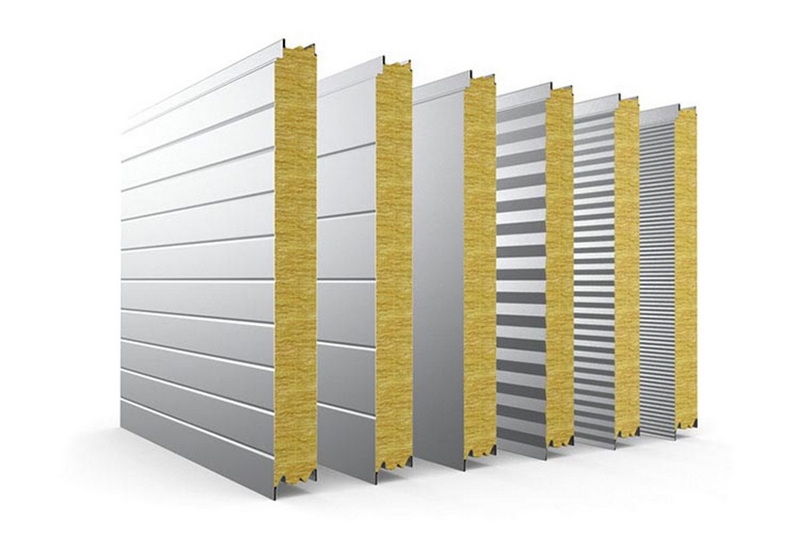

- Color Steel Sandwich Panels: TPCT offers panels with a variety of core materials including PU (polyurethane), PIR (polyisocyanurate), EPS (expanded polystyrene), and rock wool.

- Panel Thickness: They provide customizable thickness options ranging from 50mm to 150mm, tailored to meet different insulation and structural requirements.

- Steel Sheet Thickness: The upper and lower color steel sheets range from 0.3mm to 0.8mm, coated with PE, SMP, HDP, or PVDF to ensure corrosion resistance and long-lasting color durability.

- Panel Width and Length: Standard effective widths are typically 1000mm, but custom widths and lengths up to 11.8 meters or more are available depending on project needs.

- Applications: Their panels are widely used for roofing, wall cladding, ceiling panels, partitions, cold storage facilities, clean rooms, and prefab housing.

Key Features

- Fire Resistance: Panels with rock wool or PIR cores offer outstanding fireproofing capabilities, complying with international fire safety standards.

- Thermal Insulation: High-density foam cores provide excellent heat insulation, significantly reducing energy consumption in buildings.

- Waterproof and Weather Resistant: Advanced coatings and tight panel joints prevent water infiltration, making the panels suitable for harsh weather conditions.

- Environmental Sustainability: TPCT's panels are eco-friendly and recyclable, aligning with global green building initiatives.

- OEM Services: The company offers full OEM customization, including panel design, packaging, branding, and logistics solutions tailored to client requirements.

Manufacturing Capabilities

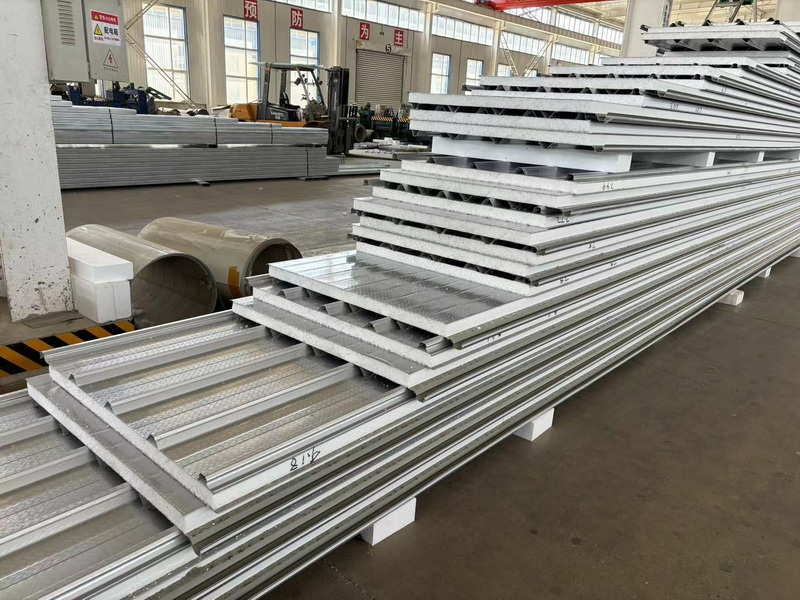

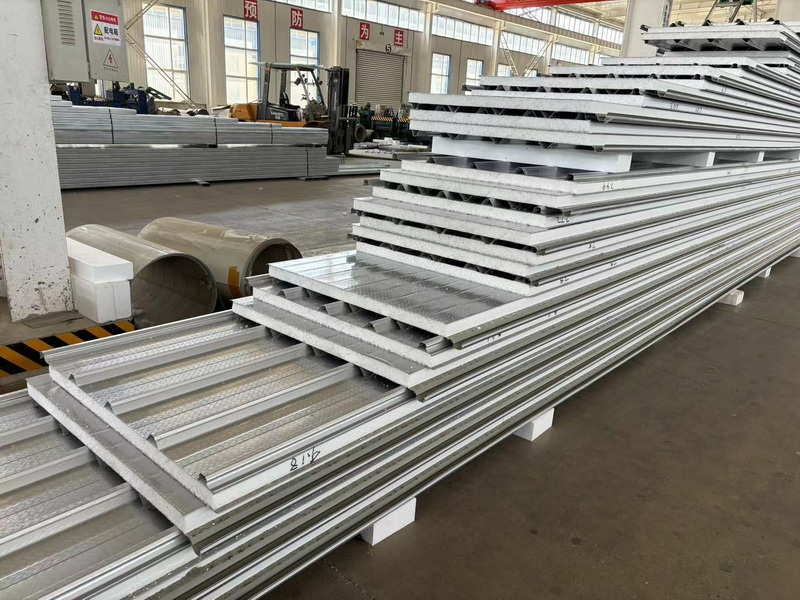

- TPCT is equipped with automatic sandwich panel production lines and advanced coating and curing systems.

- They implement strict quality control processes and hold certifications such as ISO 9001, CE, and TUV.

- Their annual production capacity exceeds 1 million square meters of sandwich panels.

- TPCT exports to over 50 countries, serving markets across Europe, the Middle East, Africa, and the Americas.

2. Foshan SAMZOON Sandwich Panel Manufacturing Co., Ltd

Located in Guangdong Province, Foshan SAMZOON specializes in color steel sandwich panels with EPS, PU, rock wool, and glass wool cores. They export extensively to Australia, the US, Europe, the Middle East, and Africa. Their panels are widely used in prefab houses, steel warehouses, and energy-efficient buildings. SAMZOON emphasizes green construction and energy-saving solutions, making them a preferred choice for eco-conscious projects.

3. Xiamen Shengqian Steel Technology Co., Ltd

Xiamen Shengqian Steel Technology, based in Fujian Province, boasts over 20 years of experience producing color steel sandwich panels. Their product lineup includes PU, EPS, and rock wool sandwich panels, as well as galvanized steel sheets. Shengqian operates large-scale production bases and multiple subsidiaries, exporting globally with ISO 9001 and ISO 14001 certifications. Their panels are popular in cold storage, industrial buildings, and commercial facilities.

4. Yantai Asa Industrial and Trading Co., Ltd

Yantai Asa is a reputable manufacturer specializing in rock wool fire-resistant sandwich panels with color steel facings. Their panels provide excellent fireproofing, thermal insulation, and water resistance, suitable for roofing, walls, ceilings, and partitions. Asa offers customized panel sizes and thicknesses, backed by a 15-year warranty and comprehensive after-sales service.

5. Shanghai Sunnyda House Co., Ltd

Shanghai Sunnyda House specializes in modular buildings and cleanroom panels, including color steel sandwich panels with PU and rock wool cores. Their products comply with ISO 9001 and CE standards and are exported to over 40 countries including the US, Germany, and the UK. Sunnyda's panels are widely used in cleanrooms, prefab offices, and industrial buildings, reflecting their commitment to quality and innovation.

6. BRDECO

BRDECO manufactures insulated sandwich panels using eco-friendly materials such as rock mineral wool. Their product range includes fireproof roofing panels and wall cladding systems suitable for residential and commercial projects. BRDECO focuses on energy-saving and fire-retardant properties, serving infrastructure and apartment building markets with reliable products.

7. Sinowa

Sinowa specializes in continuous PU sandwich panel production lines and PIR panel machines, supporting manufacturers with advanced machinery for producing color steel sandwich panels. Their technology enhances production efficiency and panel quality, making them a key equipment supplier in the industry.

8. Qingdao YMSandwich Panel Co., Ltd

Qingdao YMSandwich Panel offers customizable color steel sandwich panels with PU and PIR cores. Their panels are energy-saving, fireproof, and waterproof, with flexible thickness and color options. The company provides installation guidance and after-sales technical support, serving construction projects worldwide.

9. Zhejiang Cosasteel Co., Ltd

COSASTEEL, headquartered in Shandong, is a major steel coil and sandwich panel manufacturer. Founded in 2016, they produce high-quality color steel sandwich panels and steel coils with a focus on product innovation and quality. Their panels are widely used in industrial and commercial buildings, combining durability with aesthetic appeal.

10. Guangzhou Jet Scaffold & Formwork System Co., Ltd

Although primarily known for scaffolding, Guangzhou Jet also manufactures color steel sandwich panels for roofing and walls. Their panels emphasize durability, safety, and aesthetic appeal, supporting infrastructure and commercial construction projects with reliable products.

Additional Insights on Color Steel Sandwich Panel Manufacturing in China

Advanced Manufacturing Technologies

Leading manufacturers in China have invested heavily in modern production technologies such as automated sandwich panel production lines, robotic welding, and advanced coating systems. These technologies ensure consistent product quality, precise dimensions, and superior surface finishes, which are critical for the performance and longevity of sandwich panels.

Environmental and Safety Compliance

Chinese manufacturers increasingly adopt environmentally friendly practices, including recycling steel and foam materials and using non-toxic coatings. Compliance with international environmental standards and workplace safety regulations enhances their reputation in global markets and supports sustainable construction practices.

OEM and ODM Services

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services are widely offered by these companies. This flexibility allows foreign brands and distributors to customize color steel sandwich panels to meet specific market needs, including branding, packaging, and technical specifications. Such services are vital for companies seeking to maintain brand identity while leveraging China's manufacturing capabilities.

Logistics and Export Capabilities

China's well-developed logistics infrastructure supports efficient export of color steel sandwich panels worldwide. Major manufacturers maintain partnerships with international freight forwarders to ensure timely and cost-effective delivery. Additionally, many factories provide consolidated shipping and drop-shipping services to facilitate smooth supply chain management.

Market Trends and Innovations

The color steel sandwich panel industry in China is evolving with trends such as enhanced fire resistance, improved thermal insulation, and integration with smart building technologies. Manufacturers are also exploring new core materials and surface coatings to improve panel performance and environmental friendliness.

Conclusion

China's color steel sandwich panel manufacturers have established a strong global presence by offering high-quality, customizable, and energy-efficient panels suitable for diverse applications. Nanjing Tuopeng Construction Technology Co., Ltd leads the industry with its advanced manufacturing capabilities, comprehensive product range, and exceptional OEM services. Whether for roofing, walls, partitions, or prefab housing, these top 10 manufacturers provide reliable, fire-resistant, and environmentally friendly color steel sandwich panels that meet international standards. Partnering with these companies ensures quality, timely delivery, and professional support for global construction projects.

FAQ

1. What are the common core materials used in color steel sandwich panels?

Common cores include polyurethane (PU), polyisocyanurate (PIR), expanded polystyrene (EPS), and rock wool, each offering different insulation and fire resistance properties.

2. Can color steel sandwich panels be customized in size and color?

Yes, most manufacturers provide OEM services allowing customization of panel thickness, length, width, steel sheet thickness, and color to meet specific project requirements.

3. What are the typical applications of color steel sandwich panels?

They are widely used in roofing, wall cladding, ceilings, partitions, cold storage, clean rooms, prefab houses, warehouses, and industrial buildings.

4. How do manufacturers ensure the fire resistance of sandwich panels?

Fire resistance is ensured by using fire-retardant core materials like rock wool or PIR and by adhering to international fire safety standards such as CE and ASTM.

5. What is the typical lead time for ordering color steel sandwich panels from China?

Lead times vary by order size and customization but generally range from 20 to 45 days, depending on production schedules and shipping arrangements.

-