Content Menu

● What is Cuplock Scaffolding?

● Leading Cuplock Scaffolding Manufacturers and Suppliers in America

>> 1. DSS (Direct Scaffold Supply)

>> 2. AAIT Scaffold

● Top Chinese Manufacturers Supplying Cuplock Scaffolding to the American Market

● Why Cuplock Scaffolding Stands Out in America's Construction Industry

>> High Load Capacity and Structural Strength

>> Speed and Efficiency of Assembly

>> Versatility and Modular Adaptability

>> Durability and Corrosion Resistance

>> Compliance with Safety Standards

● Conclusion

● FAQ

>> 1. What are the main advantages of Cuplock scaffolding compared to other types?

>> 2. Can Cuplock scaffolding be customized for specific project needs?

>> 3. How to choose a trustworthy Cuplock scaffolding manufacturer or supplier in America?

>> 4. What is the role of Chinese OEM manufacturers in the American scaffolding market?

>> 5. How should Cuplock scaffolding be maintained for durability?

Cuplock Scaffolding is widely recognized as a highly efficient and robust modular scaffolding system preferred across construction and industrial projects. Featuring a unique cup-shaped locking mechanism, Cuplock scaffolding delivers unmatched load-bearing capacity, ease of installation, and flexibility in its application. This article serves as an in-depth guide to the leading Cuplock scaffolding manufacturers and suppliers operating in America, including established domestic companies and notable Chinese OEM manufacturers supplying the American market. We cover key product features, manufacturing excellence, market trends, and the benefits that make Cuplock scaffolding a top choice in the scaffolding industry.

What is Cuplock Scaffolding?

Cuplock scaffolding is a modular scaffolding system characterized by its innovative cup-and-pin locking system. Developed to provide safer, faster, and more versatile scaffolding solutions, Cuplock consists of several standardized components — vertical standards, horizontal ledgers, transoms, base jacks, and staircases or brackets when needed. The hallmark of the system is the cup-shaped node at the top and bottom of the standards, where ledgers fit and are locked securely by pins.

This design eliminates the need for nuts and bolts, substantially reducing assembly time and labor costs while increasing the structural rigidity and stability of erected scaffolds. Its modular nature allows for endless configurations, benefiting a wide array of applications — from small maintenance works to large-scale commercial construction projects.

Leading Cuplock Scaffolding Manufacturers and Suppliers in America

1. DSS (Direct Scaffold Supply)

DSS is a veteran in the American scaffolding manufacturing industry, renowned for its advanced production capabilities in Cuplock and ring lock scaffold systems. Operating out of Houston, Texas, DSS combines modern technology with stringent quality management programs to produce durable and compliant scaffolding materials. Their Cuplock products consistently meet or exceed OSHA and ANSI safety standards, ensuring optimal safety for users.

DSS offers tailored supply solutions — whether it's for industrial plants, commercial buildings, or infrastructure projects — backed by custom packaging, quality assurance certificates, and after-sales technical support. Their longstanding relationships with wholesalers and contractors reinforce DSS's prominence.

2. AAIT Scaffold

AAIT Scaffold is another major American scaffolding supplier specializing in Cuplock systems, known for its extensive distribution network and strong customer service culture. Their products have earned a reputation for reliability, high load capacity, and ease of installation. AAIT's materials are often galvanized, providing enhanced corrosion resistance suitable for outdoor and long-term projects common in America.

Moreover, AAIT offers comprehensive technical support and consultancy services to aid buyers in the selection and deployment of Cuplock scaffolding tailored to their project requirements. This customer-centric approach helps streamline procurement and optimize scaffold performance.

Top Chinese Manufacturers Supplying Cuplock Scaffolding to the American Market

Chinese manufacturers have become major suppliers for the American construction industry by offering high-quality, competitively priced Cuplock scaffolding with OEM capabilities. These companies maintain strict adherence to global manufacturing standards and export regulations.

- Rapid Scaffolding: A pioneer in innovative Cuplock scaffolding designs, Rapid Scaffolding holds certifications such as EN1090-1 and ISO3834. They emphasize product durability, safety, and flexibility, servicing multiple regions including America, the Middle East, and Europe.

- DL Group (Tianjin): Specializing in customized Cuplock scaffolding and components, DL Group is praised for quality control, an expansive product catalog (including steel frame scaffolding and accessories), and professional export services compliant with American standards.

- TSINGSHAN Metal Material Co., Ltd: Known for durable and cost-effective Cuplock scaffolding solutions, TSINGSHAN offers OEM branding and custom packaging options for international clients seeking cost efficiency without compromising safety.

By partnering with OEM suppliers such as these, American wholesalers and contractors benefit from flexible order quantities, bespoke designs, and steady raw material supply chains that make project execution more cost-effective and timely.

Why Cuplock Scaffolding Stands Out in America's Construction Industry

Several factors contribute to the growing dominance of Cuplock scaffolding in the American market, making it a preferred choice over traditional tube-and-coupler or system scaffolds:

High Load Capacity and Structural Strength

Cuplock scaffolding supports heavy construction loads safely due to its unique locking system. Each joint tightly secures horizontal and vertical components, ensuring the scaffold maintains its integrity under dynamic and static loads, crucial for high-rise buildings and infrastructural projects.

Speed and Efficiency of Assembly

The time-saving assembly process distinguishes Cuplock from other scaffolding systems. The cup lock mechanism replaces time-consuming bolts and nuts with quick-locking cups and pins, enabling faster setup and reducing labor costs. This speed translates into better project timelines and financial savings.

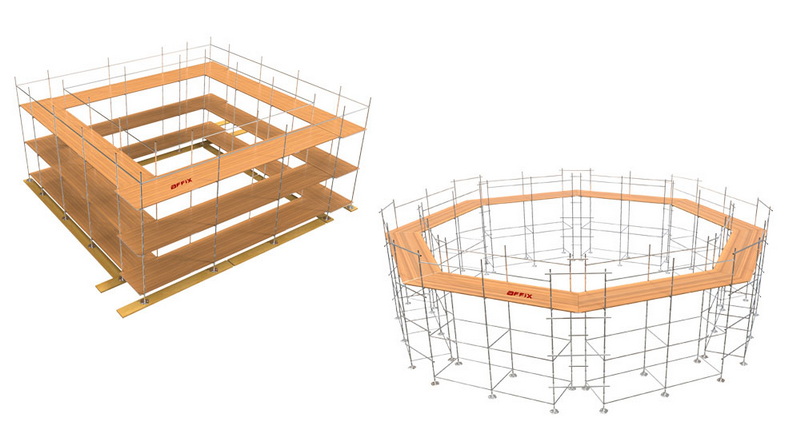

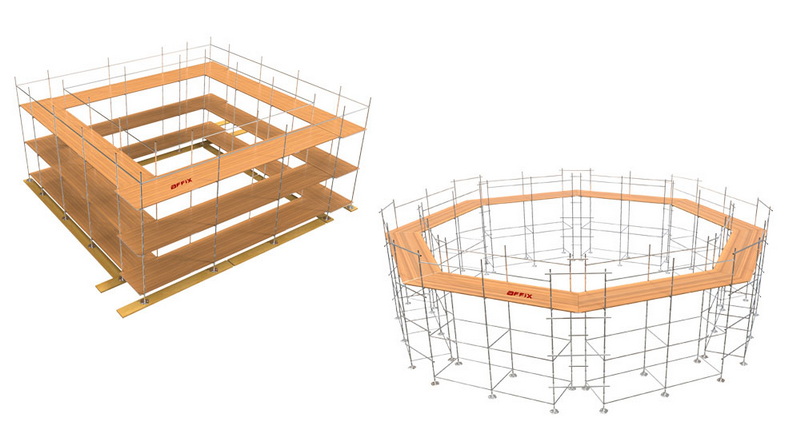

Versatility and Modular Adaptability

Cuplock scaffolds can be assembled in complex configurations with ease. Their modularity accommodates height variations, curved surfaces, and stair access without compromising stability or load capacity. This adaptability makes Cuplock suitable for diverse applications — from industrial maintenance to architectural restoration.

Durability and Corrosion Resistance

Manufacturers generally use high-quality steel, often galvanized to prevent rust and corrosion. This ensures scaffolds withstand harsh environmental conditions, increasing their usable lifespan and reducing maintenance needs.

Compliance with Safety Standards

American construction regulations and OSHA standards mandate strict scaffold safety. Cuplock scaffolding's proven reliability and high-quality manufacturing processes help users adhere to these requirements, minimizing onsite risks.

Conclusion

Cuplock scaffolding has firmly established itself as a leading solution in America's construction and industrial sectors, offering unmatched safety, assembly speed, and adaptability. American manufacturers like DSS and AAIT Scaffold have set high standards through consistent quality and customer-centric services. Simultaneously, reputable Chinese OEM manufacturers contribute by providing cost-effective, customizable Cuplock scaffolding products that meet stringent international compliance, enhancing global supply chains.

Understanding the attributes, manufacturing excellence, and market options available today empowers buyers, contractors, and brand owners to select the ideal Cuplock scaffolding supplier. This ensures safe and efficient project completion, optimizing construction outcomes and workforce safety across diverse applications.

FAQ

1. What are the main advantages of Cuplock scaffolding compared to other types?

Cuplock scaffolding offers faster assembly and dismantling, exceptional load-bearing capacity, and greater flexibility due to its modular design. Its unique cup-shaped locking system enhances safety and structural integrity, making it more reliable and efficient than traditional tube-and-coupler or frame scaffolds.

2. Can Cuplock scaffolding be customized for specific project needs?

Yes, manufacturers provide customization options such as varied lengths of ledgers and standards, optional coatings (galvanization or powder coating), and additional accessories like staircases or guardrails. OEM services by Chinese manufacturers enable branding and packaging tailored to client specifications.

3. How to choose a trustworthy Cuplock scaffolding manufacturer or supplier in America?

Evaluate manufacturers based on product certifications (ISO, EN, OSHA compliance), quality assurance procedures, years of industry experience, customer reviews, and after-sales support. Leading US-based companies such as DSS and AAIT Scaffold meet these standards and offer reliable supply chains.

4. What is the role of Chinese OEM manufacturers in the American scaffolding market?

Chinese OEM manufacturers supply competitively priced, high-quality Cuplock scaffolding components to American merchants and brands. They facilitate bulk orders with customization, comply with international standards, and help reduce procurement costs — thus complementing domestic manufacturers.

5. How should Cuplock scaffolding be maintained for durability?

Perform routine inspections for wear, corrosion, or damage; clean scaffolding components after use; store indoors away from moisture; and promptly repair or replace any defective parts to maintain scaffold safety and lifespan.