Content Menu

● What is Cuplock Scaffolding?

● The Importance of Quality in Cuplock Scaffolding Manufacturing

● Leading Cuplock Scaffolding Manufacturers and Suppliers in Australia

>> 1. Aussie Cuplock Systems

>> 2. SteelLock Scaffolding Pty Ltd

>> 3. Ironclad Cuplock Solutions

>> 4. TrueBuild Cuplock

>> 5. NextGen Cuplock Fabricators

● The Manufacturing Process of Cuplock Scaffolding in Australia

● Industry Certification and Compliance

● Applications of Cuplock Scaffolding

● OEM and Export Services

● Conclusion

● FAQ

>> 1. What materials are used in Australian cuplock scaffolding manufacturing?

>> 2. How do Australian manufacturers ensure cuplock scaffolding safety?

>> 3. What OEM options are available for cuplock scaffolding?

>> 4. Why choose cuplock scaffolding over other types?

>> 5. Are Australian cuplock scaffolding products export-ready?

Cuplock scaffolding has emerged as one of the most versatile and reliable modular scaffolding systems worldwide. Australia's construction industry benefits greatly from locally and internationally recognized manufacturers and suppliers who specialize in producing high-quality cuplock scaffolding components. Their focus on manufacturing excellence, safety compliance, and innovation ensures that Australian cuplock scaffolding remains a benchmark for durability and efficiency.This comprehensive article explores the top cuplock scaffolding manufacturers and suppliers in Australia. We delve into their manufacturing processes, product features, industry standards, and the broad range of OEM services they provide to international clients including foreign brand owners, wholesalers, and producers. If you need dependable, customized cuplock scaffolding solutions for your projects or product offerings, this detailed guide will help you make strategic sourcing decisions.

What is Cuplock Scaffolding?

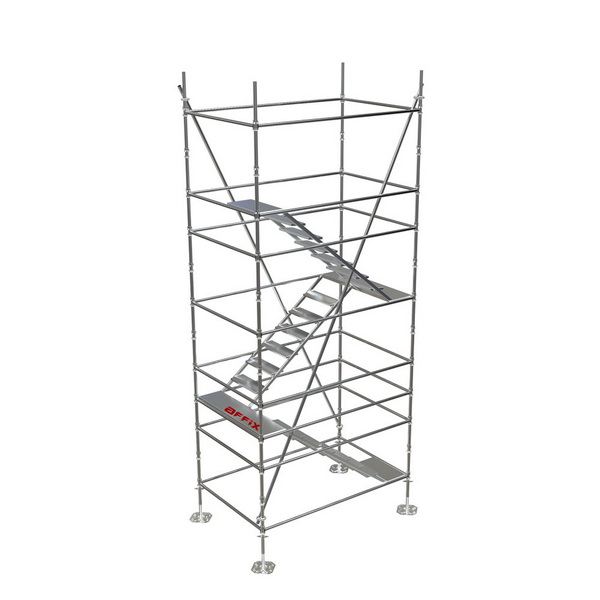

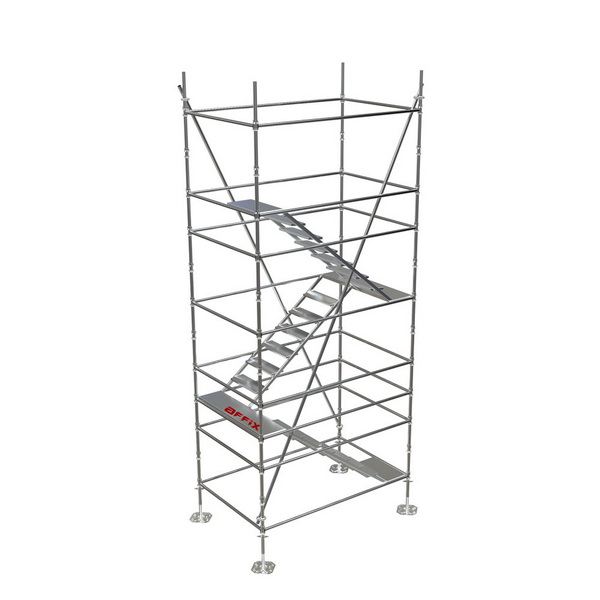

Cuplock scaffolding is a modular scaffold system distinguished by a unique locking mechanism involving cast steel or forged cups that connect vertical standards with horizontal ledgers and diagonals. The system relies on wedge locks to secure connections firmly.

The attributes of cuplock scaffolding include:

- Fast Assembly and Disassembly: The cuplock mechanism is designed for quick connection without the need for multiple bolts, resulting in significant labor savings.

- High Load Capacity: The uniform load distribution and sturdy construction provide exceptional structural stability.

- Versatility: Cuplock scaffolding systems are widely applicable in commercial, industrial, and residential construction projects.

- Enhanced Safety: The secure locking design reduces the risk of accidental dislodging, ensuring better on-site safety.

- Reusability: Due to their robustness, cuplock components can be used repeatedly over many projects, leading to long-term cost efficiency.

The combination of these features has made cuplock scaffolding the preferred choice in Australia for high-rise construction, civil infrastructure work, and maintenance scaffolding.

The Importance of Quality in Cuplock Scaffolding Manufacturing

In scaffolding, reliability directly correlates with safety. Australian manufacturers prioritize quality control across all stages:

- Material Excellence: High-quality carbon steel or alloy steel with controlled chemical compositions to meet tensile strength and ductility demands.

- Precision Forging: Cups, wedges, and standards undergo hot forging or casting followed by machining, ensuring perfect fit and strength.

- Surface Protection: Hot-dip galvanization creates a robust barrier against rust; powder coating options are available for customized aesthetics and additional protection.

- Testing and Compliance: Comprehensive testing regimes include tensile tests, impact resistance, weld integrity checks, and fatigue testing, all aligning with AS/NZS 1576 and international standards.

- Sustainability: Leading manufacturers implement environmentally responsible processes including waste reduction and energy-efficient production.

This attention to detail guarantees that cuplock scaffolding maintains high performance under extreme on-site conditions across Australia's climates — from coastal zones with heavy air moisture to interior dust-prone regions.

Leading Cuplock Scaffolding Manufacturers and Suppliers in Australia

1. Aussie Cuplock Systems

Aussie Cuplock Systems stands as a pioneer in Australia, integrating advanced forging technology with stringent quality standards.

- Offers a wide product range: standards, ledgers, bracings, base jacks, and accessories.

- Uses heavy-duty steels selected for strength and resilience.

- Holds AS/NZS 1576 certification and ISO 9001 qualification.

- Provides tailored OEM solutions including special dimension requests and surface finishes.

- Engages environmentally friendly galvanization methods reducing metal wastage and energy consumption.

They also lead in research focused on reducing component weight without compromising strength to optimize transport and handling logistics.

2. SteelLock Scaffolding Pty Ltd

SteelLock is renowned for precision-engineered cuplock scaffolding systems serving diverse sectors.

- Employs robotic forging and polishing machines for optimal finish quality.

- OEM partnerships with flexible customization capability for international clients.

- Maintains stock readiness for rapid supply within Australia and export markets.

- Provides technical consultancy services aiding clients with scaffold design and implementation.

SteelLock's proactive approach to innovation ensures their cuplock products remain competitive on durability and price.

3. Ironclad Cuplock Solutions

Ironclad delivers a comprehensive product lineup designed to support heavy-duty scaffolding needs.

- Specializes in high-wear components with enhanced surface hardening.

- Diverse coating strategies including hot-dip galvanizing and powder coating.

- Clients benefit from full OEM packaging, custom labeling, and branded document support.

- Has successfully supplied cuplock scaffolding to major Australian infrastructure projects and beyond.

Their systems are engineered for maximum compatibility, reducing downtime caused by mismatched components on site.

4. TrueBuild Cuplock

TrueBuild Cuplock integrates quality manufacturing with substantial customer service and safety training resources.

- Large cuplock inventory to meet urgent project demands.

- Supports OEM customization, including special fittings and accessories.

- Adheres to comprehensive testing protocols and Australian safety regulations.

- Provides post-sale training programs ensuring correct installation practices.

TrueBuild's commitment to client education contributes significantly to on-site safety and scaffolding longevity.

5. NextGen Cuplock Fabricators

NextGen Cuplock Fabricators specialize in sustainable production techniques combined with advanced machining technology.

- Incorporates recycled steel usage and energy-efficient forging operations.

- Offers powder coating options tinted for easy identification and branding.

- OEM producers with extensive export experience to Asia, the Middle East, and Europe.

- Emphasizes R&D for next-generation high-strength, lightweight scaffolding components.

Their dedication to eco-friendly practices attracts global clients prioritizing sustainable construction solutions.

The Manufacturing Process of Cuplock Scaffolding in Australia

Australian manufacturers employ the following comprehensive process to deliver world-class cuplock scaffolding:

1. Raw Material Selection

Steel batches are tested for essential mechanical properties and traceability. Only certified steel grades are approved for forging and fabrication.

2. Precision Forging

Critical components such as locking cups and wedges are forged at high temperatures, ensuring maximum strength and resilience to operational stress.

3. Machining and Grinding

CNC machines finish the forge products, producing exact tolerances that guarantee easy assembly and long-term fit consistency.

4. Surface Treatment

Hot-dip galvanizing is employed for a robust, corrosion-resistant finish. Powder coatings or custom finishes may be applied on demand.

5. Mechanical and Visual Inspection

Multiple testing phases include ultrasonic weld examinations, load resistance testing, and detailed visual inspections to detect flaws.

6. Packaging and OEM Branding

Finished cuplock scaffolding parts are grouped into kits, individually tagged, shrink-wrapped, and packed as specified by OEM clients, including private label branding and certification documents.

Industry Certification and Compliance

The Australian cuplock scaffolding market is underpinned by compliance with:

- AS/NZS 1576: Governs scaffolding system design, materials, and testing for Australia and New Zealand.

- ISO 9001: Ensures globally recognized quality management systems are implemented.

- CE and UKCA Marking: For products exported into Europe and the UK, satisfying regulatory demands.

- Occupational Health and Safety Standards: Scaffolding manufacturers align products with Australian WHS regulations to ensure worker safety.

- Environmental Standards: Progressive manufacturers engage with ISO 14001 and sustainability certifications.

Achieving and maintaining these certifications ensures cuplock scaffolding produced in Australia meets the highest possible standards for safety and quality assurance locally and internationally.

Applications of Cuplock Scaffolding

Australian cuplock scaffolding is widely deployed across sectors such as:

- Construction: Including residential, commercial, and high-rise developments.

- Industrial Plants: Oil, gas, mining, and energy sectors requiring strong, reliable scaffolding.

- Maintenance and Renovation: Use in infrastructure bridge work, shipyards, and power plants.

- Special Events: Temporary but secure platforms and stages.

- Civil Engineering: Large-scale infrastructure projects using modular systems.

The modularity and flexibility of cuplock scaffolding make it an ideal solution for sites demanding speed, strength, and safety.

OEM and Export Services

Major Australian cuplock scaffolding manufacturers are well versed in delivering tailored OEM services including:

- Custom sizing and finish options meeting client and market-specific requirements.

- Private labeling and packaging adapted to branding strategies.

- Full compliance documentation ensuring smooth imports and regulatory acceptance.

- Capacity for small trial runs to high-volume production.

- Export expertise with freight logistics supporting global delivery.

Such comprehensive services have positioned Australia as a respected hub for quality cuplock scaffolding, meeting global demand with precision and consistency.

Conclusion

Australia's cuplock scaffolding manufacturers and suppliers are synonymous with quality, innovation, and safety. Their ability to produce robust, compliant, and versatile scaffolding components has made them trusted partners in the global construction market.

International brand owners, wholesalers, and manufacturers seeking OEM collaborations will find that Australian suppliers offer unparalleled product quality, flexible customization, and proven export capabilities. Choosing Australian cuplock scaffolding equates to securing durable, efficient, and safe scaffolding solutions that support successful projects worldwide.

FAQ

1. What materials are used in Australian cuplock scaffolding manufacturing?

Manufacturers commonly use certified high-strength carbon or alloy steel, subjected to hot-dip galvanization or powder coating for corrosion protection.

2. How do Australian manufacturers ensure cuplock scaffolding safety?

By complying with AS/NZS 1576 standards, ISO 9001 quality management, and performing comprehensive mechanical and corrosion resistance testing.

3. What OEM options are available for cuplock scaffolding?

Manufacturers provide custom sizing, private labeling, bespoke packaging, and full quality documentation servicing global clients with flexible order volumes.

4. Why choose cuplock scaffolding over other types?

Cuplock scaffolding offers rapid assembly, exceptional load performance, enhanced safety from secure locking mechanisms, and long service life.

5. Are Australian cuplock scaffolding products export-ready?

Yes, with certifications such as AS/NZS standards, CE, and UKCA markings, Australian cuplock scaffolding components are designed and packaged for smooth export worldwide.