Content Menu

● Introduction to Cuplock Scaffolding

● The Growing Korean Cuplock Scaffolding Market

● Leading Cuplock Scaffolding Manufacturers and Suppliers in Korea

>> 1. Dong Myung Industrial Co., Ltd.

>> 2. Steel Korea Co., Ltd.

>> 3. Hory Korea Co., Ltd.

>> 4. KS Form

>> 5. Viser System Co., Ltd.

● Components and Features of Cuplock Scaffolding Systems

● Applications of Cuplock Scaffolding in Korea

● Technological Innovations in Korean Cuplock Scaffolding

● Role of Chinese OEM Manufacturers in Korea's Cuplock Market

● Key Features to Evaluate When Selecting Cuplock Scaffolding Manufacturers and Suppliers

● Advantages of Cuplock Scaffolding Systems

● Conclusion

● FAQ

>> 1. What key certifications should Korean Cuplock scaffolding manufacturers have?

>> 2. Can Chinese OEM manufacturers supply custom Cuplock scaffolding for the Korean market?

>> 3. How do Korean suppliers ensure the safety and quality of Cuplock scaffolding?

>> 4. What kinds of support do manufacturers offer for specialized or complex projects?

>> 5. Are rental services for Cuplock scaffolding common in Korea?

Cuplock scaffolding systems are highly regarded in Korea's construction industry for their modular design, safety, rapid assembly, and versatility. For a Chinese scaffolding material manufacturer providing OEM services to foreign brands, wholesalers, and producers, gaining insight into Korea's Cuplock scaffolding manufacturers and suppliers is crucial for building strong business partnerships and expanding market access. This comprehensive article offers an in-depth overview of Korea's top Cuplock scaffolding manufacturers and suppliers, highlights their product features, technological innovations, applications, and OEM collaboration dynamics.

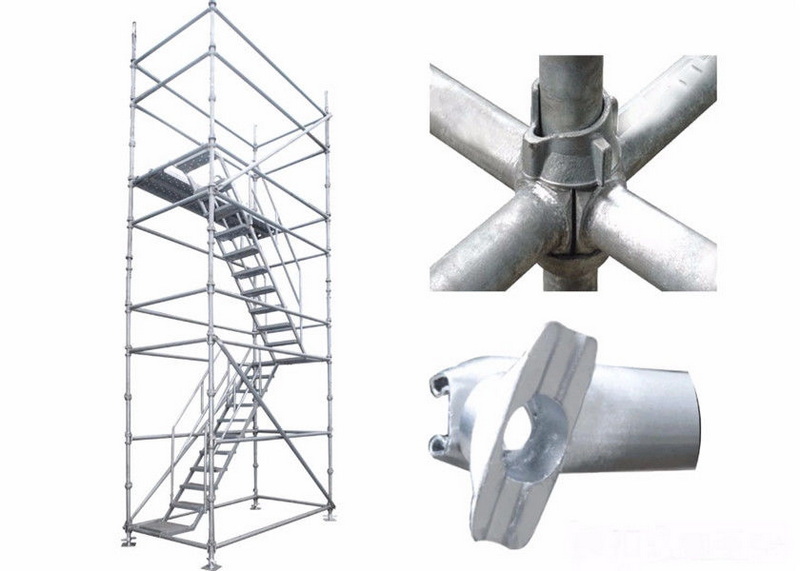

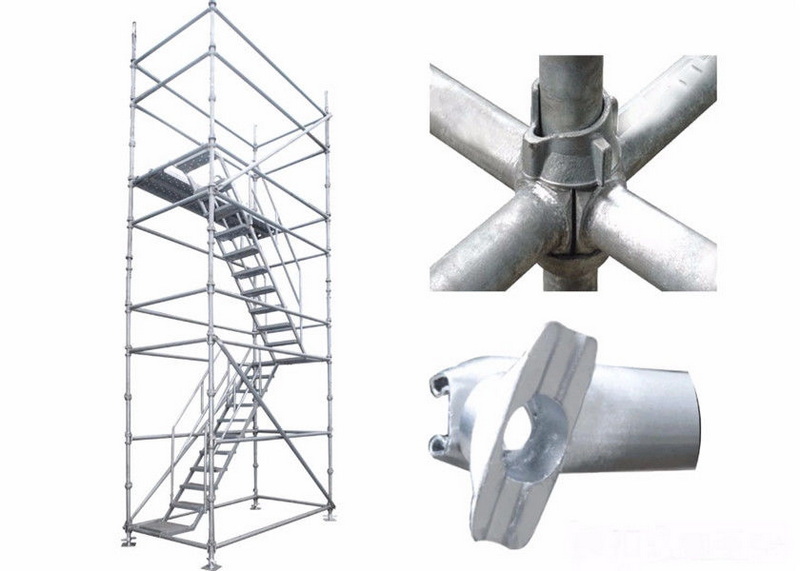

Introduction to Cuplock Scaffolding

Cuplock scaffolding is a modular steel tube system featuring a unique locking cup and wedge mechanism that connects the vertical standards to horizontal ledgers quickly and securely. This mechanism facilitates fast erection and dismantling, which significantly improves project efficiency and ensures worker safety. Globally favored for large-scale construction, industrial maintenance, and infrastructure projects, Cuplock scaffolding fits well with Korea's strict construction standards and fast-paced building industry.

Korean manufacturers emphasize high-quality standards complying with domestic regulations and international certifications, ensuring products have robust load capacities, durability, and adaptable configurations suited for Korea's diverse construction environment.

The Growing Korean Cuplock Scaffolding Market

Korea's construction sector emphasizes safety, efficiency, quality, and sustainability. The market demand for Cuplock scaffolding stems from several factors:

- Stringent Safety Regulations: Korean construction projects mandate scaffolding certified against local and international standards, ensuring worker protection.

- Technological Development: Korean manufacturers incorporate advanced fabrication techniques like robotic welding and CNC precision cutting.

- Diverse Applications: Cuplock systems are widely used across residential, commercial, industrial, and infrastructure projects.

- Strong Export and OEM Activities: Korean manufacturers actively export and collaborate with Chinese OEM suppliers to optimize cost and product customization.

- Rental and Sales Options: A robust market for both sales and rental services supports varied contractor needs.

Leading Cuplock Scaffolding Manufacturers and Suppliers in Korea

Here are some of the foremost Korean companies specializing in Cuplock scaffolding systems:

1. Dong Myung Industrial Co., Ltd.

- Location: Seocho-dong, Seocho-gu, Seoul

- Profile: Established in 1992, Dong Myung is a well-established local scaffolding manufacturer with over 100 employees and about 70 engineers dedicated to product quality.

- Product Range: Steel pipe props, steel planks, scaffolding frames, and scaffold couplers.

- Export Markets: Southeast Asia, Middle East

- Strengths: Strong engineering team, high product quality, and wide product coverage.

2. Steel Korea Co., Ltd.

- Location: Hwasung-city, Gyeonggi-do

- Profile: A manufacturer focusing on scaffolding pipes, props, steel planks, and mobile scaffold towers supplying domestic and international markets.

- Certifications: Includes product certifications listed on their official platforms.

- Highlights: Export services worldwide with a clear product line and technical data transparency.

3. Hory Korea Co., Ltd.

- Location: Gimhae-si, Gyeongsangnam-do

- Background: Founded in 2000, Hory Korea specializes in steel pipe scaffolding, ringlock scaffolding, Euro forms, and scaffolding ledgers.

- Export Focus: Southeast Asia and East Asia markets including Japan, Russia, Cambodia, Philippines, and Vietnam.

- Key Products: Steel pipes, ringlock scaffolding, and system scaffolding accessories.

4. KS Form

- Location: Gangnam-gu, Seoul

- Profile: Specializes in domestic manufacturing of standards, jack bases, and ringlock ledgers, ensuring minimal reliance on imports.

- Market Role: Helps reduce shipping costs and ensures prompt domestic availability.

5. Viser System Co., Ltd.

- Locations: Gimhae-si, Gyeongsangnam-do (head office); Ortigas Center, Pasig City (collaboration factory)

- Profile: Established in 2004 with OEM and distribution contracts including partnerships with global firms such as Samsung Heavy Industries.

- Product Range: Ringlock scaffolding, jack bases, scaffold pipes.

- Key Strength: Strong OEM partnership experience and export capability enhancing product reliability.

Components and Features of Cuplock Scaffolding Systems

Korean Cuplock scaffolding emphasizes high-precision, durable components with efficient assembly systems:

- Standards (Vertical Tubes): Equipped with bottom locking cups receiving the ledgers securely.

- Ledgers (Horizontal Tubes): Connect perpendicularly with standards via the patented cuplock cup and wedge system.

- Transoms: Provide cross-platform support enhancing load capacity and working platform stability.

- Cup Locks: A distinctive wedge and cup mechanism facilitating fast, secure joint connections without extra tools.

Applications of Cuplock Scaffolding in Korea

Cuplock scaffolding serves a wide array of construction and industrial applications, including:

- Residential and Commercial Projects: Multi-story building scaffolds for construction and renovations.

- Industrial Maintenance: Facilities like power plants, factories, petrochemical plants requiring strong, safe scaffolds.

- Infrastructure and Civil Engineering: Bridges, highways, tunnels benefiting from modular and easily adaptable scaffolding.

- Marine and Offshore Industries: Corrosion-resistant components suitable for shipyards and port facilities.

- Temporary Structures: Event stages, exhibition setups, emergency access scaffolding that needs rapid assembly and dismantling.

Technological Innovations in Korean Cuplock Scaffolding

Korean manufacturers employ several innovations to enhance Cuplock scaffolding performance:

- Advanced Welding and Fabrication Methods: Use of robotics and CNC machinery for precision and weld strength.

- Corrosion Resistant Coatings: Hot-dip galvanization and durable paint finishes optimize durability in harsh environments.

- Digital Design Integration: CAD and BIM software assist project planning, layout optimization, and reduce assembly errors.

- Sustainability Focus: Emphasis on recycling steel materials and reducing waste in manufacturing facilities.

Role of Chinese OEM Manufacturers in Korea's Cuplock Market

Chinese manufacturers providing OEM services have become key suppliers to Korean scaffolding companies:

- Customization: Tailored designs, coatings, and specifications adhering to Korean and international standards (like EN 74, BS1139).

- Quality Compliance: Rigorous testing to meet JIS (Japanese Industrial Standards) or ISO requirements often required by Korean contractors.

- Supply Chain Efficiency: Fast and reliable shipments supporting Korean manufacturers' domestic and export needs.

- Cost Advantages: Competitive pricing allows Korean suppliers to remain cost-effective without compromising product safety.

This collaboration strengthens Korea's scaffolding supply chain by offering flexibility, innovation, and economic advantages.

Key Features to Evaluate When Selecting Cuplock Scaffolding Manufacturers and Suppliers

1. Certifications and Standards Compliance: Verify EN 74, BS1139, ISO, and local Korean safety certifications.

2. Engineering and Technical Support: Availability of design consultation, on-site assembly training, and post-sale technical assistance.

3. OEM/ODM Capabilities: Flexibility in product customization to meet project-specific and branding requirements.

4. Logistics and Delivery: Efficient supply chain management for timely and reliable delivery.

5. Reputation and Reliability: Partner with manufacturers having solid industry experience and positive customer feedback.

Advantages of Cuplock Scaffolding Systems

- Fast and Easy Assembly: Reduces labor costs and construction timelines.

- High Load Capacity: Supports demanding industrial and infrastructure projects.

- Enhanced Safety: Secure single locking cup system reduces joint failure risks.

- Modular Versatility: Flexible for complex site conditions and varying heights.

- Durability and Maintenance: Resistant to corrosion with minimal maintenance requirements.

Conclusion

Korea's Cuplock scaffolding market features reputable manufacturers such as Dong Myung Industrial, Steel Korea, Hory Korea, KS Form, and Viser System. These companies deliver high-quality, certified scaffolding products tailored for Korea's rigorous construction and industrial requirements.

Chinese OEM manufacturers support this ecosystem by providing customizable, cost-effective, and certified Cuplock scaffolding components ensuring smooth supply chains and competitive pricing.

Together, these partnerships foster safe, efficient, and flexible Cuplock scaffolding solutions that drive Korea's construction industry forward while maintaining high standards of safety and innovation.

FAQ

1. What key certifications should Korean Cuplock scaffolding manufacturers have?

Key certifications include EN 74, BS1139, ISO 9001, and any Korean national safety approvals to ensure structural integrity and compliance.

2. Can Chinese OEM manufacturers supply custom Cuplock scaffolding for the Korean market?

Yes, many Chinese OEM suppliers offer customized scaffolding components matching Korean regulations on size, coating, and branding, supporting local manufacturers' needs.

3. How do Korean suppliers ensure the safety and quality of Cuplock scaffolding?

Korean manufacturers implement automated fabrication, strict in-house quality control, third-party certification testing, and continuous R&D to meet evolving standards.

4. What kinds of support do manufacturers offer for specialized or complex projects?

Suppliers often provide engineering consulting, customized technical documentation, on-site training, and assembly supervision to ensure safe and accurate installations.

5. Are rental services for Cuplock scaffolding common in Korea?

Yes, both sales and rental options exist, with many suppliers offering flexible rental solutions for short-term or project-based requirements.