Content Menu

● Understanding Forged Couplers and Their Critical Role in Scaffolding

● Germany's Forged Couplers Manufacturing Industry: An Overview

● Leading Forged Couplers Manufacturers and Suppliers in Germany

>> 1. BauForge GmbH

>> 2. Sicherheit Steel Components

>> 3. MetallForm Solutions

>> 4. EuroCouplers AG

>> 5. FerroTech Industrial Solutions

● Why Choose German Forged Couplers Manufacturers and Suppliers?

● How OEM Forged Coupler Manufacturing Benefits Global Scaffold Brands

● Forged Couplers' Impact on Scaffold Construction Safety and Efficiency

● Emerging Trends in Germany's Forged Coupler Industry

● Conclusion

● FAQ

>> 1. What are forged couplers and why are they preferred in scaffolding?

>> 2. How to identify trusted forged coupler manufacturers and suppliers in Germany?

>> 3. What types of forged couplers are commonly produced in Germany?

>> 4. Can forged couplers be customized by manufacturers?

>> 5. Are German forged couplers compliant with European safety standards?

The scaffolding and construction industries rely heavily on the strength, safety, and precision of their components. Among these, forged couplers play a vital role as connectors that guarantee the integrity and rigidity of scaffold structures. Germany, renowned for its engineering excellence and advanced manufacturing sector, is home to some of the world's most reputable forged couplers manufacturers and suppliers. These companies combine cutting-edge technology, outstanding quality control, and stringent adherence to international standards to deliver forged couplers that meet the highest demands.This article explores the top forged coupler manufacturers and suppliers in Germany, outlines their manufacturing capabilities, and highlights why they are preferred suppliers worldwide.

Understanding Forged Couplers and Their Critical Role in Scaffolding

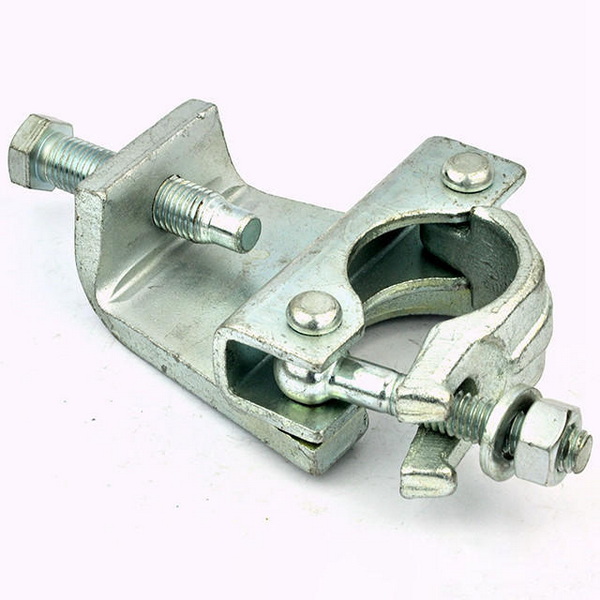

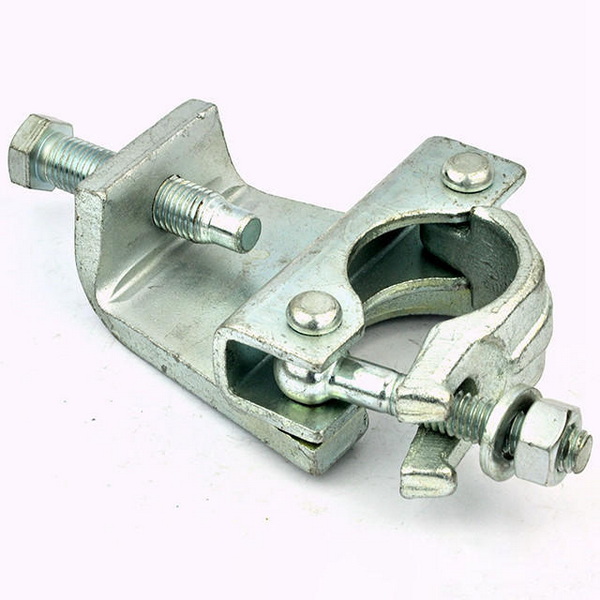

Forged couplers are components forged from steel billets under intense pressure, aligning the metal's grain structure and resulting in superior mechanical properties such as strength, toughness, and fatigue resistance. These characteristics are essential for scaffolding applications where safety is paramount.

Typical forged coupler types include:

- Right-angle couplers: Fixed perpendicular connections, joining vertical and horizontal pipes.

- Swivel couplers: Allow angular flexibility, facilitating complex scaffold geometries.

- Sleeve couplers: Join scaffold tubes end-to-end to extend lengths.

Choosing trusted forged coupler manufacturers and suppliers ensures scaffolding projects are structurally robust and compliant with international safety regulations.

Germany's Forged Couplers Manufacturing Industry: An Overview

Germany's forged coupler manufacturing sector is driven by a culture of precision engineering. Key features include:

- Use of high-grade steel alloys sourced both locally and internationally, adhering to DIN standards (Deutsches Institut für Normung).

- Advanced manufacturing utilizing hydraulic forging presses, automated CNC machining, and robotic finishing.

- Application of sophisticated heat treatment and corrosion prevention processes, including galvanizing and powder coating.

- Rigorous compliance with quality management certifications like ISO 9001 and adherence to European standards (EN 74), ensuring all products carry CE marking.

- Strong focus on customization and OEM production for scaffold manufacturers seeking tailored solutions with specific mechanical properties and branding.

German forged coupler suppliers often work closely with their clients to optimize design, improve durability, and meet tight project deadlines.

Leading Forged Couplers Manufacturers and Suppliers in Germany

1. BauForge GmbH

BauForge GmbH is widely respected in Germany for their innovation in forged coupler manufacturing.

- Extensive product range including right-angle, swivel, and sleeve couplers.

- Modern automated forging presses combined with CNC machining.

- In-house metallurgical and mechanical testing labs.

- Strong OEM manufacturing partnerships focusing on quality and scalability.

2. Sicherheit Steel Components

Sicherheit Steel Components focuses on safety-critical forged couplers designed for industrial and commercial scaffolding.

- Specialized heat treatment for enhanced fatigue resistance.

- Compliance with DIN and EN safety standards.

- Wide customer base in Europe and global export experience.

- OEM and private label service with full traceability.

3. MetallForm Solutions

Offering integrated forging and finishing solutions, MetallForm Solutions serves scaffold manufacturers looking for reliable couplers with quick turnaround.

- Lean manufacturing system integrating forging, CNC machining, and finishing.

- Dedicated OEM production with design consultation.

- Continuous improvement focused on efficiency and sustainability.

4. EuroCouplers AG

EuroCouplers AG delivers premium forged couplers with high customization flexibility.

- Advanced production lines equipped with robotic forging and inspection.

- Surface coatings optimized for weather resistance, including hot-dip galvanizing.

- Collaborations with major European scaffold brands.

5. FerroTech Industrial Solutions

FerroTech specializes in high-strength forged couplers for challenging environments including oil & gas and heavy industrial sectors.

- Proprietary heat treatment enhancing toughness.

- Full-spectrum coupler types available.

- OEM production with extensive technical support.

Why Choose German Forged Couplers Manufacturers and Suppliers?

German manufacturers and suppliers of forged couplers bring several significant advantages to scaffolding brands globally:

- Engineering Excellence: Precision manufacturing using cutting-edge technology ensures high-quality and consistent products.

- Compliance & Certifications: Products meet DIN, EN 74, ISO 9001, and have CE marking, reassuring safety and legal requirements.

- Comprehensive OEM Services: Capability to design and produce fully customized forged couplers tailored to brand-specific needs.

- Sustainability Commitment: Increasing adoption of energy-efficient processes and recyclable materials aligns with global environmental policies.

- Strategic Location & Export Networks: Ideal connectivity enables efficient shipping throughout Europe and worldwide.

- Quality Assurance: Rigorous testing including tensile, impact, and corrosion assessments guarantees reliability.

Our Chinese manufacturing factory values cooperation with German forged coupler producers and international scaffold brand owners, providing OEM services that blend cost-efficiency with German-level quality standards.

How OEM Forged Coupler Manufacturing Benefits Global Scaffold Brands

OEM partnerships with German forged coupler manufacturers enable scaffold brands to:

- Access top-tier forged coupler technology without investing in expensive facilities.

- Customize mechanical specifications, coatings, packaging, and branding offsets.

- Ensure conformity to European regulatory norms while speeding market entry.

- Benefit from expert engineering and technical support throughout product lifecycle.

- Optimize supply chain efficiency with dependable lead times and quality consistency.

Our factory is experienced in OEM collaborations with German and other international suppliers, bridging manufacturing excellence and scalable production to meet worldwide demand.

Forged Couplers' Impact on Scaffold Construction Safety and Efficiency

Forged couplers influence scaffold projects by:

- Mechanical Strength: Their superior tensile strength ensures scaffold stability under heavy loads.

- Corrosion Resistance: Protective coatings preserve components in exposure to weather and chemicals.

- Installation Ease: Precisely engineered couplers fit seamlessly, reducing assembly time and error.

- Design Flexibility: Swivel couplers provide angular adjustments to facilitate complex scaffold structures.

- Long Service Life: Durable forging and heat treatment reduce maintenance and replacement costs.

German forged coupler manufacturers maintain high-quality production standards supporting these benefits, essential for regulatory compliance and worker safety.

Emerging Trends in Germany's Forged Coupler Industry

Industry leaders in Germany are driving innovation with trends such as:

- Industry 4.0 Integration: Smart manufacturing incorporating IoT, real-time data analytics, and robotics for quality and efficiency.

- Advanced Material Science: Development of lighter, stronger alloys and optimized heat treatments.

- Eco-Friendly Manufacturing: Use of renewable energy, eco-conscious waste management, and recyclable packaging.

- Tailored OEM Solutions: Collaboration in design engineering to meet niche scaffold market demands.

- Lightweight & Hybrid Materials: Exploration of aluminum and composite forged couplers for portable scaffold systems.

These developments ensure Germany's forged coupler manufacturers stay at the forefront globally.

Conclusion

Germany's forged couplers manufacturers and suppliers combine precision engineering, rigorous quality assurance, and sustainability to deliver top-tier forged couplers trusted worldwide. Their extensive OEM capabilities ensure scaffold brands gain customized, compliant, and reliable products.

Our China-based OEM manufacturing factory collaborates with German forged coupler producers and international scaffold companies, providing competitively priced, high-quality forged couplers aligned with German standards. This partnership fosters safer scaffolding solutions globally.

Choosing trusted forged couplers manufacturers and suppliers in Germany is a strategic investment in scaffold safety, efficiency, and market success.

FAQ

1. What are forged couplers and why are they preferred in scaffolding?

Forged couplers are connectors formed under compressive forging, providing superior strength, toughness, and fatigue resistance critical for scaffold safety and durability.

2. How to identify trusted forged coupler manufacturers and suppliers in Germany?

Look for ISO 9001, DIN, EN 74 certifications, state-of-the-art production facilities, OEM experience, and documented quality control systems.

3. What types of forged couplers are commonly produced in Germany?

Right-angle (fixed), swivel (rotatable), and sleeve (end-to-end) couplers catering to various scaffold applications.

4. Can forged couplers be customized by manufacturers?

Yes, German manufacturers offer OEM services supporting custom sizes, materials, finishes, and packaging to meet brand needs.

5. Are German forged couplers compliant with European safety standards?

Yes, they meet EN 74 standards, carry CE marking, and undergo rigorous mechanical and corrosion testing for EU scaffold regulations.