Content Menu

● Introduction to Kwikstage Scaffolding

● The Growing Kwikstage Scaffolding Market in America

● Leading Kwikstage Scaffolding Manufacturers and Suppliers in America

>> 1. Safway Group

>> 2. Z Scaffold

>> 3. Advanced Scaffold & Shoring Inc.

>> 4. Sunbelt Rentals Scaffolding Group

>> 5. Aluma Systems

● Kwikstage Scaffolding Components and Features

● Industrial Applications of Kwikstage Scaffolding in America

● Technological Innovations in the American Kwikstage Scaffolding Market

● Role of Chinese OEM Manufacturers in America's Kwikstage Market

● Key Considerations When Choosing Kwikstage Scaffolding Manufacturers and Suppliers

● Advantages of Kwikstage Scaffolding Systems

● Conclusion

● FAQ

>> 1. What certifications should American Kwikstage scaffolding manufacturers hold?

>> 2. Can Chinese OEM manufacturers supply Kwikstage scaffolding customized for the American market?

>> 3. What technical and after-sales support do suppliers typically offer?

>> 4. How does Kwikstage scaffolding improve efficiency on construction projects?

>> 5. Is rental of Kwikstage scaffolding common in America?

Kwikstage scaffolding systems are widely recognized in America's construction sector for their modular design, rapid assembly, excellent safety features, and versatility across various projects. For a Chinese scaffolding material manufacturer providing OEM services to foreign brands, wholesalers, and producers, understanding the key Kwikstage scaffold manufacturers and suppliers in America is essential for expanding business opportunities and establishing strong partnerships. This comprehensive article explores leading American suppliers and manufacturers of Kwikstage scaffolding, the system's components, industrial applications, technological innovations, OEM collaboration, and answers frequently asked questions.

Introduction to Kwikstage Scaffolding

Kwikstage scaffolding is a modular steel tube system known for its unique star-profile vertical standards and simple wedge locking horizontals, which are designed to enable fast and secure assembly and disassembly. The system consists of vertical standards with pre-punched, star-shaped holes, ledgers that connect horizontally using wedge locks, transoms for platform support, and base jacks for leveling uneven ground.

Widely employed in commercial and residential building projects, industrial maintenance, and infrastructure construction, Kwikstage scaffolding is prized in America for its stability, high load-bearing capacity, and adaptability to complex architectural requirements.

The Growing Kwikstage Scaffolding Market in America

America's booming construction industry relies heavily on efficient, safe, and flexible scaffolding systems, and Kwikstage scaffolding fits these needs well due to:

- Safety & Compliance: American safety standards require scaffolding systems to meet OSHA regulations and standards such as ANSI/SSFI (Scaffold & Access Industry Association). Top manufacturers ensure products comply with these standards.

- Project Efficiency: Fierce deadline pressures and dynamic site conditions drive contractors to prefer Kwikstage for its rapid assembly and dismantling, reducing labor time and costs.

- Diverse Applications: Kwikstage scaffolding is employed in urban high-rises, bridge construction, industrial plants, and event staging, demonstrating high versatility.

- OEM Opportunities: Increasing partnerships with Chinese manufacturers and suppliers provide customized, cost-effective Kwikstage solutions tailored for the US market.

- Sales and Rentals: Both options are well developed in America, allowing contractors to optimize equipment deployment per project size and duration.

Leading Kwikstage Scaffolding Manufacturers and Suppliers in America

1. Safway Group

- Location: Headquarters in St. Louis, Missouri, USA

- Overview: Safway Group is a major provider of access and scaffolding solutions in the US with comprehensive Kwikstage scaffolding offerings. They specialize in system scaffolds for construction and industrial maintenance, featuring national rental capabilities and technical support.

- Strengths: Extensive inventory, strong safety record, nationwide rental and sales network.

2. Z Scaffold

- Location: Multiple locations including Florida, California, and Texas

- Overview: Z Scaffold supplies Kwikstage scaffolding and accessories across America. They focus on innovation, high-quality steel components, and customizations for complex projects.

- Highlights: Fabrication services plus scaffolding component sales, including custom-ledger lengths and powder-coated finishes to enhance durability and corrosion resistance.

3. Advanced Scaffold & Shoring Inc.

- Location: Texas, USA

- Overview: Offers Kwikstage scaffolding tailored to meet American construction industry requirements.

- Products: Includes Kwikstage systems, shoring, formwork, and scaffolding accessories for commercial and civil projects.

- Value: Strong engineering support, onsite consultation, and rapid shipping services.

4. Sunbelt Rentals Scaffolding Group

- Location: Nationwide USA coverage

- Overview: As part of the Sunbelt Rentals brand, they supply Kwikstage scaffolding for short or long-term rental to contractors across America.

- Features: Modern, well-maintained inventory, flexible rental solutions backed by technical support and service.

5. Aluma Systems

- Location: Boston, Massachusetts, USA

- Overview: Manufacturer and supplier of aluminum and steel scaffolding including Kwikstage systems.

- Emphasis: Lightweight systems with robust design, compliance with ANSI and OSHA standards, and customization services for OEM clients.

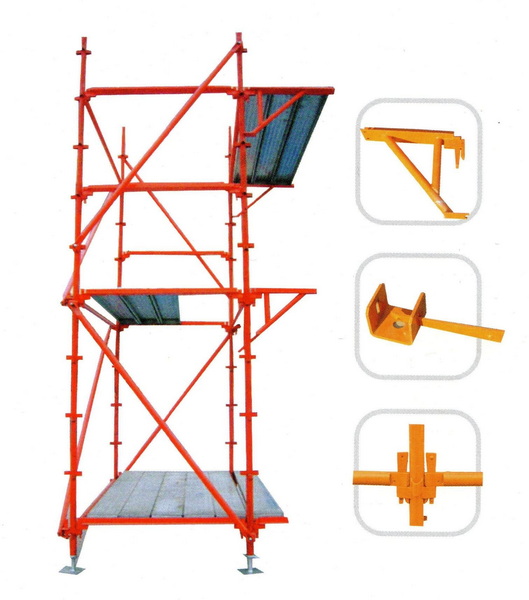

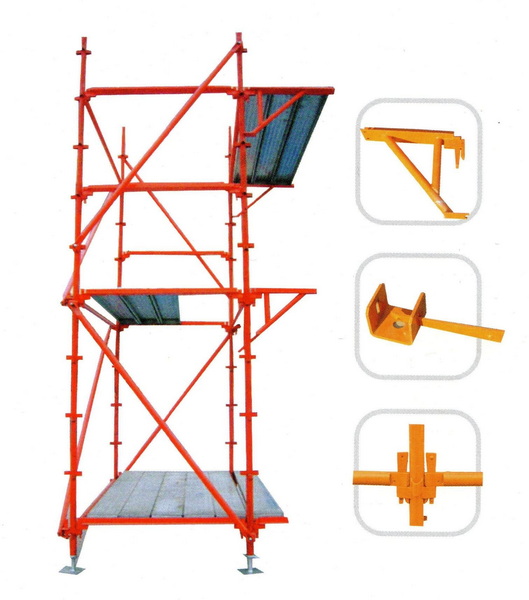

Kwikstage Scaffolding Components and Features

- Standards (Verticals): Steel tubes with star-shaped holes at regular intervals to attach ledgers quickly.

- Ledgers (Horizontals): Connect standards via pressed wedge locks that do not require loose pins or bolts, enabling one-move assembly.

- Transoms: Support scaffold boards and evenly distribute load.

- Base Jacks: Adjustable feet for leveling scaffolding on uneven or sloped ground.

- Toe Boards and Guardrails: Ensuring safety on working platforms by preventing tool or personnel falls.

Industrial Applications of Kwikstage Scaffolding in America

- Commercial and Residential Construction: Scaffold platforms for multi-story buildings, facade work, and renovations.

- Infrastructure: Bridge construction and repair, highway projects requiring complex, adaptable scaffold layouts.

- Industrial Facilities: Refineries, power plants, and warehouses utilize Kwikstage scaffolding for maintenance access and structural support.

- Events and Temporary Structures: Concert and stadium staging, temporary overhead protection roofing constructions.

- Shipyards and Ports: Corrosion-resistant scaffolding versions suitable for maritime and coastal installations.

Technological Innovations in the American Kwikstage Scaffolding Market

- Material Advancements: Use of galvanized and powder-coated steel enhances corrosion protection and extends lifespan.

- Modular Design Enhancements: Components are designed for rapid interchangeability and accommodate heavier load capacities.

- Digital Planning Tools: CAD and BIM technologies used for scaffolding layout design, risk assessments, and project simulation reduce onsite errors.

- OEM Customization: Ability to produce tailor-made components for client-specific needs, optimizing erection time and site safety.

- Sustainability: Increasing use of recycled steel and environmentally responsible manufacturing processes reflect industry's eco-conscious trends.

Role of Chinese OEM Manufacturers in America's Kwikstage Market

Chinese manufacturers, including your factory, play a strategic role by supplying high-quality, certified Kwikstage scaffolding parts to the American market:

- Customization: OEM production adapts to US standards such as ANSI and OSHA, including tailored dimensions, coatings, and branding.

- Quality Assurance: Products comply with ASTM, ISO, and EN standards frequently required by American customers.

- Cost Efficiency: Competitive pricing helps American distributors and contractors maintain profitability while meeting safety norms.

- Supply Chain Reliability: Streamlined logistics ensure just-in-time deliveries, supporting timely project execution.

This partnership strengthens the American Kwikstage scaffolding supply chain, enhances product innovation, and broadens market options.

Key Considerations When Choosing Kwikstage Scaffolding Manufacturers and Suppliers

1. Certifications and Compliance: Verify adherence to OSHA, ANSI, ASTM, ISO, and EN standards ensuring safety and proven durability.

2. Engineering and Technical Services: Availability of design consultation, on-site training, and after-sales technical support.

3. OEM/ODM Capabilities: Flexibility for customization and private labeling tailored to client needs.

4. Supply Chain and Logistics: Efficient inventory management and timely delivery to avoid project delays.

5. Industry Reputation: Preference for suppliers with solid experience, strong safety records, and positive customer feedback.

Advantages of Kwikstage Scaffolding Systems

- Fast Assembly/Disassembly: Enables time and labor savings with wedge-lock connections and modular components.

- High Load Capacity: Suitable for heavy-duty industrial and complex construction projects.

- Enhanced Safety: Provides secure locking and stable framework reducing fall and joint failure risks.

- Versatile and Modular: Flexible system easily adaptable to complex architectural and site conditions.

- Durable and Low Maintenance: Materials and coatings ensure corrosion resistance and long service life.

Conclusion

The American Kwikstage scaffolding market benefits from the presence of reputable manufacturers and suppliers such as Safway Group, Z Scaffold, Advanced Scaffold & Shoring Inc., Sunbelt Rentals Scaffolding Group, and Aluma Systems. These entities combine extensive product ranges with strict adherence to safety and quality standards, offering dependable solutions across diverse construction, industrial, and infrastructure projects.

Chinese OEM manufacturers support this ecosystem by providing customizable, certified, and competitively priced Kwikstage scaffolding components, contributing to a robust, efficient supply chain in the US market.

Together, these collaborations ensure that projects throughout America have access to safe, flexible, and efficient Kwikstage scaffolding systems that meet the highest industry standards.

FAQ

1. What certifications should American Kwikstage scaffolding manufacturers hold?

Manufacturers should comply with OSHA, ANSI, ASTM, and preferably ISO or EN standards to ensure safety and product quality.

2. Can Chinese OEM manufacturers supply Kwikstage scaffolding customized for the American market?

Yes, many reputable Chinese OEMs provide fully customized components that comply with American safety regulations, including dimensions, coatings, and branding options.

3. What technical and after-sales support do suppliers typically offer?

Support includes comprehensive project design consultation, on-site assembly training, maintenance guidance, and detailed technical documentation.

4. How does Kwikstage scaffolding improve efficiency on construction projects?

Modular design with wedge locks facilitates rapid assembly and dismantling, reducing labor requirements, shortening project durations, and minimizing downtime.

5. Is rental of Kwikstage scaffolding common in America?

Yes, many suppliers and rental companies provide flexible leasing options alongside outright sales, enabling contractors to manage costs and equipment use according to project length and budget.