Content Menu

● What is Kwikstage Scaffolding?

● Leading Kwikstage Scaffolding Manufacturers and Suppliers in Germany

>> Steeledge GmbH

>> German Distributors Partnering with Chinese OEM Manufacturers

>> Rapid Scaffold (China-Based but Global Reach)

● Product Features Emphasized by German Manufacturers and Suppliers

>> 1. High-Quality Materials

>> 2. Advanced Corrosion Protection

>> 3. Modular Design for Easy Assembly and Versatility

>> 4. Intercompatibility and Flexibility

>> 5. Stricter Compliance and Safety

● The Rise of OEM Kwikstage Scaffolding Manufacturers from China for the German Market

>> Competitive Pricing Through Direct Factory Supply

>> Customization Services

>> Robust Quality Control Systems

>> Comprehensive After-Sales and Technical Support

>> Scalable Production Capacity

● Application and Market Trends in Germany

● Conclusion

● FAQ

>> 1. What makes Kwikstage scaffolding popular among German manufacturers and suppliers?

>> 2. How is the quality of Kwikstage scaffolding ensured?

>> 3. Can Kwikstage scaffolding be customized for specific projects?

>> 4. What materials are commonly used in Kwikstage scaffolding manufacturing?

>> 5. How do Chinese OEM manufacturers serve the German market effectively?

Kwikstage scaffolding is among the most widely used modular scaffolding systems worldwide, prized for its versatility, speed of assembly, and robustness. In Germany, a country with a flourishing construction industry and stringent safety and quality standards, the demand for reliable Kwikstage scaffolding manufacturers and suppliers is substantial. This article dives deeply into the top manufacturers and suppliers of Kwikstage scaffolding in Germany, with a particular emphasis on OEM collaborations with reputable Chinese factories. We explore product features, market trends, benefits of OEM sourcing, and how these companies meet the precise needs of the German construction market.

What is Kwikstage Scaffolding?

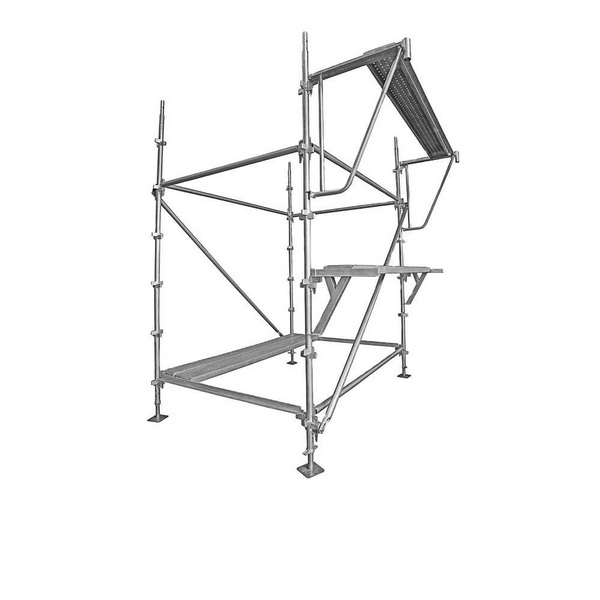

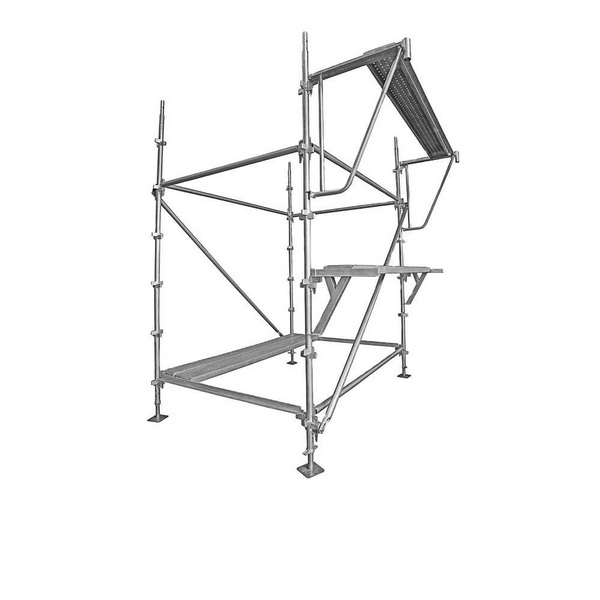

Kwikstage scaffolding is a modular system comprised mainly of vertical standards, horizontal ledgers, transoms, base jacks, and scaffold boards. Its hallmark is the wedge and pin connection mechanism that enables quick, tool-free assembly and dismantling, dramatically reducing labor and downtime on site. This system's modularity allows easy adaptation to complex structures of various heights and types, making it a favorite in commercial, residential, and industrial construction projects.

The design inherently emphasizes safety, flexibility, and load-bearing efficiency, complying with rigorous European and international safety standards. Used extensively in Germany, Kwikstage scaffolding fosters safer work environments and accelerates project timelines.

Leading Kwikstage Scaffolding Manufacturers and Suppliers in Germany

Germany's scaffolding market boasts numerous reputable manufacturers and suppliers who meet the demand for high-quality Kwikstage systems through production, rental, and distribution.

Steeledge GmbH

Steeledge GmbH is a key player recognized for producing robust Kwikstage scaffolding tailored for diverse sectors such as building construction, civil engineering, and even DIY applications. Their commitment to using premium materials and meeting stringent quality controls explains their leading role in the German and European markets.

German Distributors Partnering with Chinese OEM Manufacturers

Several German distributors collaborate closely with Chinese OEM manufacturers to provide scalable, customizable scaffold solutions. Chinese manufacturers like Shandong Zeemo Construction Technology Co., Ltd and Guangzhou AJ Building Material Co., Ltd have garnered trust due to their high-quality steel frames and protective finishes. These manufacturers produce Kwikstage scaffolding components from Q235 and Q355 grade steel with thicknesses ranging from 2.75 mm to 3.2 mm, covered by hot-dip galvanization or powder coatings to ensure durability against harsh weather elements and site chemicals.

This partnership model benefits German wholesalers and brand owners by ensuring:

- Competitive pricing due to removed middlemen.

- Tailored designs that meet specific project needs or branding demands.

- Reliable logistics for timely project deliveries.

- Strong technical and after-sales support.

Rapid Scaffold (China-Based but Global Reach)

Rapid Scaffold, a prominent Chinese scaffold supplier, services the German market with Kwikstage and other modular scaffolding solutions. Like other Chinese OEMs, Rapid Scaffold focuses on strict quality assurance, cost-effectiveness, and flexible customization, delivering excellent service combined with fast shipping and large-volume production capacity.

Product Features Emphasized by German Manufacturers and Suppliers

A close examination of German Kwikstage scaffolding suppliers reveals several quality and performance benchmarks that are highly valued:

1. High-Quality Materials

German and OEM manufacturers use premium steel grades (Q235/Q355) to ensure structural stability and weight-bearing capability. Higher grades and adequate thickness minimize deformation and extend operational lifespan.

2. Advanced Corrosion Protection

Hot-dip galvanization remains the gold standard due to its superior rust resistance, essential for outdoor scaffolding exposed to rain and chemicals. Powder coatings offer additional aesthetic options, with multiple color choices allowing companies to differentiate their products visually.

3. Modular Design for Easy Assembly and Versatility

The wedge connection system is a distinct advantage. It allows fast setup without specialized tools, reducing labor costs significantly and enabling site workers to adapt scaffolds to complex geometries effortlessly.

4. Intercompatibility and Flexibility

Components are manufactured to fit seamlessly with other types of scaffolding systems like Ringlock and Frame scaffolds, enhancing flexibility on multi-system construction sites—a feature appreciated across Germany's diverse projects.

5. Stricter Compliance and Safety

German standards require rigorous adherence to EN norms such as EN 12810 and EN 12811 governing scaffold design, load capacity, and safety requirements. Many suppliers incorporate multiple quality testing phases, including load testing, welding inspections, and dimensional accuracy checks.

The Rise of OEM Kwikstage Scaffolding Manufacturers from China for the German Market

OEM partnerships with Chinese manufacturers fuel a significant portion of the German scaffold supply chain. Several advantages make these collaborations valuable:

Competitive Pricing Through Direct Factory Supply

By cutting out intermediaries, German wholesalers and brands obtain competitive prices for high-quality Kwikstage scaffolding. Chinese manufacturers operate at large scales with efficient production techniques, lowering per-unit costs.

Customization Services

OEM factories accommodate specific project or brand demands, including customized dimensions, unique finish colors, logo branding, and packaging styles. This flexibility allows German clients to meet niche market or project requirements beyond standard catalog offerings.

Robust Quality Control Systems

Top Chinese OEMs implement rigorous quality monitoring throughout the production cycle: from raw material sourcing to final inspection. This ensures consistent product safety, reliability, and compliance with European standards.

Comprehensive After-Sales and Technical Support

Chinese OEMs often provide extensive support packages, including installation guidance, defect management, and onsite training. This collaborative customer approach builds trust with German partners.

Scalable Production Capacity

German market dynamics require quick adaptation to fluctuating demand levels, especially amid large infrastructure projects. Chinese manufacturers adeptly scale production volumes up or down, ensuring steady supply without sacrificing quality.

Application and Market Trends in Germany

Germany's construction industry is heavily investing in infrastructure modernization, commercial redevelopment, and urban housing projects—segments where Kwikstage scaffolding excels. Growing safety awareness and regulatory pressures elevate the demand for compliant and reliable scaffolding systems. Furthermore, Germany's rental market for scaffolding is expanding, emphasizing modular systems like Kwikstage for their reusability and ease of transport.

German manufacturers and suppliers also face increasing interest in eco-friendly and sustainable manufacturing. Some OEMs are exploring environmentally safer coatings and efficient material usage to align with Germany's green building standards.

Conclusion

Germany's robust construction sector relies on dependable, efficient scaffolding systems, with Kwikstage scaffolding standing out due to its modularity, safety, and speed of assembly. Leading German manufacturers like Steeledge GmbH maintain high-quality standards within the country, while considerable sourcing from top Chinese OEM scaffolding factories ensures competitive pricing, customization, and reliable supply chains. The combination of local expertise and international manufacturing capacity allows German wholesalers, brand owners, and producers to access premium Kwikstage scaffolding that aligns perfectly with their project requirements and market demands.

By understanding product features, manufacturer capabilities, and cooperative global supply dynamics, businesses can make informed decisions to leverage Kwikstage scaffolding's benefits fully in Germany's construction and industrial landscapes.

FAQ

1. What makes Kwikstage scaffolding popular among German manufacturers and suppliers?

Kwikstage scaffolding is highly favored due to its modular, quick-assembly design, enhancing site safety and reducing labor time. The system's adaptability to various heights and configurations suits Germany's wide-ranging construction projects, from residential buildings to industrial complexes.

2. How is the quality of Kwikstage scaffolding ensured?

Manufacturers uphold strict quality control protocols including the use of premium-grade steel, precise welding, and protective coatings such as hot-dip galvanization or powder paint. Compliance with European construction standards and frequent inspections safeguard product durability and user safety.

3. Can Kwikstage scaffolding be customized for specific projects?

Absolutely. Most OEM manufacturers offer tailored sizes, finishes, proprietary branding, and packaging solutions. This customization capability enables German clients to receive scaffolds suited exactly to project, branding, and operational needs.

4. What materials are commonly used in Kwikstage scaffolding manufacturing?

Generally, Q235 and Q355 steel brands are employed for frame strength, accompanied by corrosion-resistant coatings like zinc galvanization or powder coatings to protect scaffolds from rust and damage.

5. How do Chinese OEM manufacturers serve the German market effectively?

Chinese factories provide cost-effective, high-quality Kwikstage scaffolding with strong production flexibility and customization options. Through partnerships with German distributors, they offer comprehensive technical and after-sales support, ensuring timely delivery and satisfaction.