Content Menu

● What is Kwikstage Scaffolding?

● Leading Kwikstage Scaffolding Manufacturers and Suppliers in Japan

>> 1. Shinwa Co., Ltd.

>> 2. SANKYO Corporation

>> 3. DAISAN Co., Ltd.

>> 4. SUGIKO Group

>> 5. Additional Noteworthy Manufacturers and Suppliers

● Product Features and Quality Standards Emphasized by Japanese Manufacturers

>> High-Grade Materials and Fabrication

>> Corrosion Resistance and Durability

>> Strict Compliance with Regulations

>> Safety Innovations and Accessories

>> Customization and OEM Flexibility

>> Sustainable Production Practices

● The Role of Chinese OEM Manufacturers in Japan's Kwikstage Market

>> Competitive Pricing

>> Customization to Local Needs

>> Rigorous Quality Assurance

>> Technical and After-Sales Support

>> Scalable Supply Capabilities

● Conclusion

● FAQ

>> 1. What makes Kwikstage scaffolding popular among Japanese manufacturers and suppliers?

>> 2. How do Japanese manufacturers ensure quality of Kwikstage scaffolding?

>> 3. Can Kwikstage scaffolding be customized for Japanese projects?

>> 4. What materials are typically used in Japanese Kwikstage scaffolding?

>> 5. How do Chinese OEM manufacturers support Japanese scaffolding suppliers?

Kwikstage scaffolding is a modular system highly valued worldwide for its rapid assembly, safety, and outstanding adaptability. Japan, renowned for its precision engineering, strong construction regulations, and technological innovation, has a well-established sector of Kwikstage scaffolding manufacturers and suppliers. These companies combine traditional craftsmanship with state-of-the-art production processes to meet strict Japanese Industrial Standards (JIS) and international safety regulations such as EN 12810 and EN 12811.

What is Kwikstage Scaffolding?

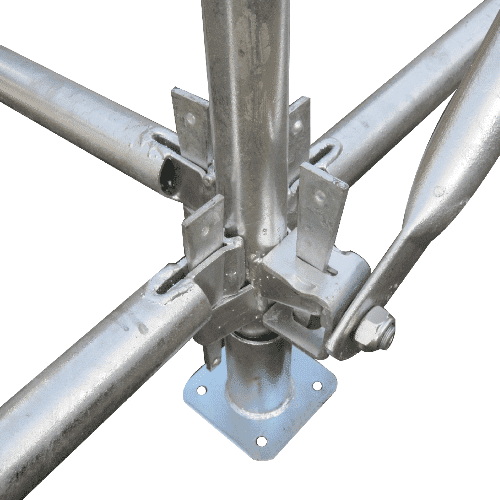

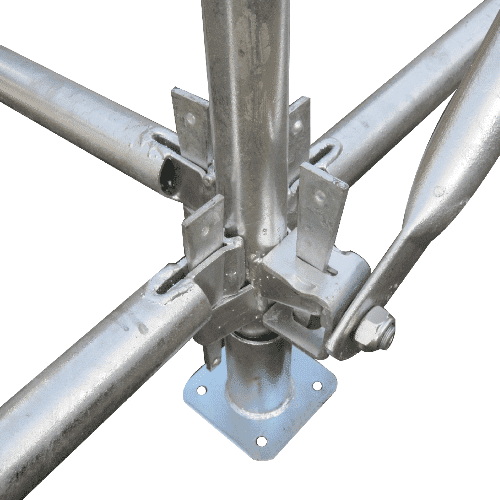

Kwikstage scaffolding consists of several modular components, primarily vertical standards, horizontal ledgers, transoms, base jacks, and scaffold boards. These parts are joined using wedge-pin connections, facilitating quick, tool-free assembly and dismantling. This modularity enables rapid setup and flexibility to accommodate various building heights and layouts — a key factor driving its widespread use in construction, industrial maintenance, and event staging projects across Japan.

The system is designed to be robust and versatile while ensuring safety for workers at height. Japanese manufacturers frequently incorporate innovations driven by automation and material science to tailor Kwikstage scaffolding to meeting Japan's rigorous safety codes and site conditions.

Leading Kwikstage Scaffolding Manufacturers and Suppliers in Japan

Japan's Kwikstage scaffolding market features some distinguished companies known for quality, innovation, and compliance with demanding safety standards.

1. Shinwa Co., Ltd.

Founded in 1979, Shinwa Co., Ltd. is a major player headquartered in Gifu Prefecture. With a workforce exceeding 160 employees and sales over 17 billion JPY in 2019, Shinwa produces a wide range of scaffolding systems including Kwikstage, ringlock, and tubular scaffolds. The company is highly regarded for its focus on sustainability, reliability, and safety. Its Kwikstage products are tailored for dense urban construction projects, infrastructure maintenance, and large-scale development sites. Shinwa also provides a variety of scaffolding accessories such as steel pallets and safety nets to enhance onsite efficiency and protection.

2. SANKYO Corporation

Established in Osaka in 1972, SANKYO Corporation sells Kwikstage scaffolding with an emphasis on walk-through frame types that promote worker mobility and safety. Beyond sales, SANKYO offers rental and installation services along with high-quality safety nets customized for scaffolding applications. Their products are frequently used in commercial, civil engineering, and industrial construction projects all across Japan.

3. DAISAN Co., Ltd.

Based in Osaka and founded in 1975, DAISAN specializes exclusively in Kwikstage scaffolding, diagonal braces, and steel planks. The company is ISO 9001 certified, highlighting its commitment to quality management. DAISAN invests heavily in employee training and professional development to ensure safe scaffolding use and compliance with Japanese regulations. Their products are known for durability, precision, and ease of installation, earning trust among Japanese builders and contractors.

4. SUGIKO Group

With roots dating back to 1953, the SUGIKO Group operates multiple sales offices nationwide including Tokyo, Aichi, Osaka, and Shinchi. While prominently known for ringlock scaffolding, SUGIKO also supplies Kwikstage scaffolding systems, staircases, toe boards, and braces — addressing the full scaffolding needs of complex construction sites.

5. Additional Noteworthy Manufacturers and Suppliers

- HEIWA GIKEN Co., Ltd: Specialized in producing cross braces, couplers, and joint components compatible with Kwikstage and many other scaffolding types.

- KESARA LLC: Offers quality-assured second-hand frame scaffolding tailored for cost-conscious buyers and SMEs.

- KYC Machine Industry Co., Ltd: Known for manufacturing precision ringlock scaffolding and galvanized steel planks, serving a nationwide customer base.

- Nisso Industries Co., Ltd: Supplies scaffolding frames, toe boards, and related accessories widely used in civil engineering and maintenance projects.

Product Features and Quality Standards Emphasized by Japanese Manufacturers

Japanese manufacturers and suppliers highlight several crucial attributes to ensure their Kwikstage scaffolding meets customer needs:

High-Grade Materials and Fabrication

Steel raw materials used are of premium grade, cold-formed and heat-treated to achieve excellent mechanical strength and load capacity. Automated robotic welding and CNC machining guarantee dimensional accuracy and consistent quality across components.

Corrosion Resistance and Durability

Due to Japan's varied climate, high corrosion protection is essential. Most components undergo hot-dip galvanization, which offers robust resistance to rust even under harsh environmental conditions. Powder coating is another common protective finish, providing an additional layer of protection and aesthetic appeal.

Strict Compliance with Regulations

Japanese manufacturers ensure full compliance with:

- Japanese Industrial Standards (JIS) specific to scaffolding steel tubes and components.

- ISO 9001 and other relevant certifications ensuring quality management frameworks.

- EN 12810 & EN 12811 European standards widely referenced for scaffold equipment safety and performance.

Rigorous product testing, including load-bearing capacity, welding integrity, and dimensional inspections, ensures onsite safety and reliability.

Safety Innovations and Accessories

Beyond the standard components, many manufacturers offer integrated safety features, such as staircases, toe boards, guardrails, and safety netting systems. These provide enhanced fall protection and facilitate safe movement for construction workers.

Customization and OEM Flexibility

Japanese manufacturers commonly provide tailored solutions regarding:

- Tube dimensions and thickness

- Coating options (galvanized, painted, powder-coated)

- Branding (colored finishes, logos, serial markings)

- Packaging and logistics

This flexibility supports domestic brands and international OEM clients wanting scaffolding customized for Japanese or regional project specifications.

Sustainable Production Practices

Several companies prioritize recycling steel scrap, minimizing emissions during galvanizing, and using energy-efficient machinery as part of Japan's drive for sustainable manufacturing processes within the construction sector.

The Role of Chinese OEM Manufacturers in Japan's Kwikstage Market

While Japan has strong local manufacturing capacities, partnerships with Chinese OEM scaffolding manufacturers offer compelling advantages for Japanese wholesalers and construction brands:

Competitive Pricing

Chinese factories benefit from economies of scale and lower labor costs, enabling them to produce cost-effective Kwikstage scaffolding components without compromising quality. Direct shipping reduces intermediaries, resulting in attractive pricing for Japanese clients.

Customization to Local Needs

Chinese OEM suppliers tailor products to meet Japan's structural, dimension, and aesthetic requirements, including JIS conformity and client-specific branding.

Rigorous Quality Assurance

Top-tier Chinese factories adopt comprehensive quality management systems, including raw material validation, welding inspections, corrosion resistance testing, and third-party certifications to meet international standards closely aligned with those in Japan.

Technical and After-Sales Support

OEM manufacturers often provide training, installation manuals, on-site assistance, and prompt defect resolution to ensure successful deployments in Japan's demanding construction environments.

Scalable Supply Capabilities

Large infrastructure or seasonal projects occasion surges in scaffolding demand where Chinese OEMs can rapidly scale production volumes while maintaining consistent delivery schedules.

Conclusion

Japan's Kwikstage scaffolding manufacturers and suppliers represent a fusion of decades of engineering expertise, cutting-edge manufacturing technology, and uncompromising safety standards. Renowned companies such as Shinwa Co., Ltd., SANKYO Corporation, and DAISAN Co., Ltd. deliver modular scaffolding solutions characterized by high durability, rapid assembly, and customization suited to diverse construction and industrial applications throughout Japan.

In parallel, expanding collaborations with Chinese OEM manufacturers provide Japanese wholesalers and brands with competitively priced, customizable, and quality-compliant scaffolding components. This synergy of local precision and scalable international manufacturing ensures continued access to premium Kwikstage scaffolding systems fulfilling Japan's strict safety requirements and evolving project needs.

Understanding these manufacturers' capabilities, product innovations, and supply chain dynamics enables Japanese construction professionals, wholesalers, and brand owners to make more informed procurement decisions, ensuring scaffold safety, operational efficiency, and cost-effectiveness.

FAQ

1. What makes Kwikstage scaffolding popular among Japanese manufacturers and suppliers?

Kwikstage scaffolding's modular design and wedge-pin tool-free assembly ensure rapid erection and dismantling with high safety. Its adaptability to different project scopes and compliance with stringent Japanese safety regulations make it an ideal choice across construction, industrial, and event sectors.

2. How do Japanese manufacturers ensure quality of Kwikstage scaffolding?

Through strict adherence to Japanese Industrial Standards (JIS), ISO quality systems, automated production, use of premium steel material, hot-dip galvanization for corrosion protection, and multiple inspection phases, manufacturers guarantee durable, reliable, and compliant scaffolding products.

3. Can Kwikstage scaffolding be customized for Japanese projects?

Yes. Manufacturers and Chinese OEM partners provide customized scaffold dimensions, coatings (such as galvanizing or colors), branding logos, and packaging tailored to client and project needs.

4. What materials are typically used in Japanese Kwikstage scaffolding?

High-quality carbon steel, cold-formed and heat-treated, is standard for frame components. Hot-dip galvanization is most common for corrosion resistance, with optional powder coating or painting for additional protection and visual requirements.

5. How do Chinese OEM manufacturers support Japanese scaffolding suppliers?

They offer competitive, quality-assured Kwikstage components with flexibility for customization, strong production scalability, and technical support services, helping Japanese suppliers manage costs and meet complex market demands efficiently.