Content Menu

● What is Kwikstage Scaffolding?

● Leading Kwikstage Scaffolding Manufacturers and Suppliers in Korea

>> Dong Myung Industrial Co., Ltd.

>> Steel Korea Co., Ltd.

>> Seobo Industrial Co., Ltd.

>> Hory Korea Co., Ltd.

>> KS Form

>> Viser System Co., Ltd.

● Key Product Features and Quality Standards by Korean Manufacturers and Suppliers

>> High-Quality Steel Materials

>> Corrosion-Resistant Coatings

>> Innovative and Precise Manufacturing Techniques

>> Certifications and Compliance

>> OEM Customization Expertise

>> Export Potency

● Advantages of OEM Partnerships with Korean Kwikstage Manufacturers for Foreign Brands

● Conclusion

● FAQ

>> 1. What distinguishes Korean Kwikstage scaffolding manufacturers and suppliers?

>> 2. How is the quality of Kwikstage scaffolding ensured by Korean manufacturers?

>> 3. Can Korean Kwikstage scaffolding be customized for specific international projects?

>> 4. What are the primary materials used in Korean Kwikstage scaffolding?

>> 5. How do OEM collaborations with Korean manufacturers benefit foreign brands or wholesalers?

Kwikstage scaffolding is a modular scaffolding system globally recognized for its fast assembly, excellent safety features, and remarkable adaptability across different construction and industrial environments. South Korea, a country with a strong industrial base, advanced production technologies, and growing global trade connections, has fostered a mature and innovative Kwikstage scaffolding manufacturing sector. Korean manufacturers and suppliers demonstrate high technical standards, meticulous quality management, and export-ready capabilities. This article offers an extensive overview of Korea's leading Kwikstage scaffolding manufacturers and suppliers, highlighting their product features, certifications, manufacturing strengths, and OEM service capabilities tailored specifically for foreign brands, wholesalers, and producers.

What is Kwikstage Scaffolding?

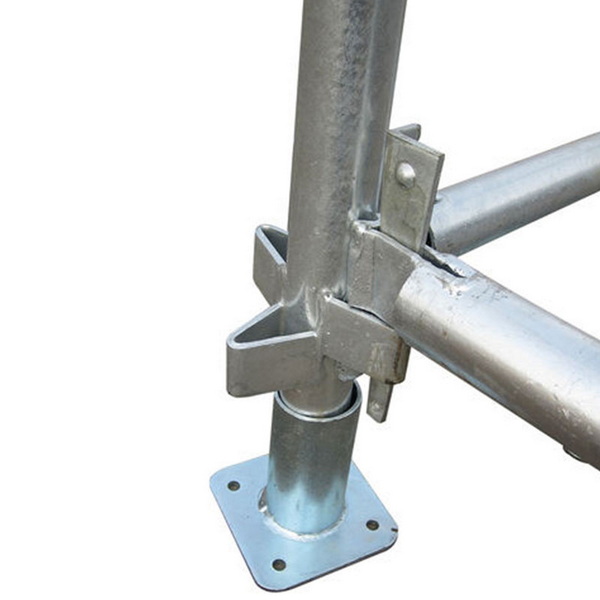

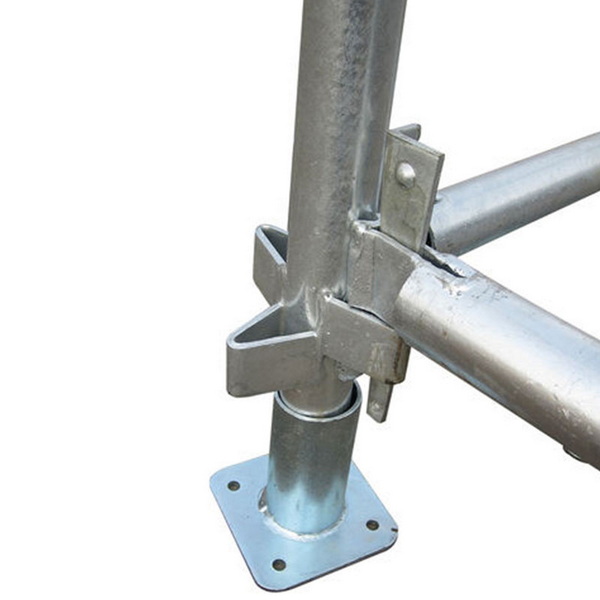

Kwikstage scaffolding is composed of modular components primarily including vertical standards, horizontal ledgers, transoms, base jacks, and scaffold boards. These parts are connected via wedge-pin and clasp systems allowing rapid, tool-free assembly and dismantling. The modular design makes it ideal for flexible height adjustment and spatial configurations, fitting a wide range of construction, maintenance, and event staging projects.

South Korean manufacturers incorporate advanced materials such as high-strength cold-formed steel, combined with corrosion-resistant coatings, to guarantee durable and compliant scaffolding frameworks. The system's structural strength and safety compliance make it popular domestically and internationally.

Leading Kwikstage Scaffolding Manufacturers and Suppliers in Korea

South Korea is home to several well-established and reputable Kwikstage scaffolding manufacturers and suppliers, many of whom actively provide OEM services to foreign brands and wholesalers.

Dong Myung Industrial Co., Ltd.

Founded in 1992 and located in Seocho-gu, Seoul, Dong Myung Industrial is a prominent Korean scaffolding manufacturer. Its product range encompasses steel pipe props, steel planks, versatile frame scaffolding components, and aluminum planks. With a robust quality control system and R&D focus, Dong Myung serves both domestic and international customers, exporting primarily to Southeast Asia and the Middle East. Their emphasis on durability and certification ensures products meet diverse international standards.

Steel Korea Co., Ltd.

Operating out of Hwaseong-si, Gyeonggi-do, Steel Korea is a major supplier specializing in scaffold pipes, steel planks, mobile scaffold towers, and formwork materials. Their products enjoy strong market recognition for excellent corrosion resistance, thanks to their advanced galvanization processes and stringent production controls. Steel Korea also actively exports worldwide, providing full quality certification for international clients.

Seobo Industrial Co., Ltd.

Headquartered in Chungcheongbuk-do and founded in 1998, Seobo Industrial produces a wide array of scaffolding accessories, aluminum planks, bridge formwork, and scaffold props. Certified under ISO 9001 for quality management and ISO 14001 for environmental compliance, Seobo is committed to sustainable manufacturing practices. Their network includes sales offices in Seoul and global partners.

Hory Korea Co., Ltd.

Based in Gimhae, Gyeongsangnam-do, Hory Korea specializes in steel pipe fabrication, ringlock scaffolding systems, Euro forms, ledgers, clamps, and scaffolding accessories. With initial capital investment from Japan's SRG Group, Hory Korea benefits from international joint venture expertise. The company exports extensively to Japan, Southeast Asia, and East Asia, maintaining high standards for quality assurance and customer service.

KS Form

A Seoul-based company focusing predominantly on domestic scaffolding materials, KS Form manufactures scaffold standards, jack bases, and ringlock ledgers. Their local production enables rapid delivery and cost-effective pricing, particularly catering to Korea's booming construction projects.

Viser System Co., Ltd.

Located in Gimhae, Viser System partners with major industrial players such as Samsung Heavy Industries and Japanese OEM manufacturers. Viser produces ringlock scaffolding, jack bases, and scaffold pipes, focusing on large infrastructure and industrial applications requiring stringent safety and quality standards.

Key Product Features and Quality Standards by Korean Manufacturers and Suppliers

Korean Kwikstage scaffolding manufacturers emphasize a comprehensive set of features and certifications to maintain product quality and market competitiveness:

High-Quality Steel Materials

Most manufacturers use cold-formed premium-grade steel tubes to ensure superlative mechanical strength and load capacity. Precision machining and strict metallurgical controls guarantee consistent dimensional and durability attributes essential for safe scaffolding.

Corrosion-Resistant Coatings

Resistance to rust and environmental damage is critical. Korean scaffolding components typically undergo advanced hot-dip galvanization processes; powder coatings or painted finishes are often applied as secondary protections to extend lifespan, especially in coastal or industrial environments prone to corrosion.

Innovative and Precise Manufacturing Techniques

Many Korean factories integrate automated welding robots, CNC cutting machines, and computerized quality inspection systems, producing scaffolding components with tight tolerances and reliable dimensional accuracy—supporting quick, secure assembly on-site.

Certifications and Compliance

Korean manufacturers maintain adherence to international standards and certifications including:

- ISO 9001 Quality Management System certification, ensuring consistent manufacturing quality.

- ISO 14001 Environmental Management certification promoting sustainable production.

- Compliance with related regional and international scaffolding safety norms commonly required for export markets.

OEM Customization Expertise

Manufacturers boast the capacity to provide fully customized Kwikstage scaffolding solutions tailored to client specifications. These include modifications to scaffold dimensions, steel thickness, surface treatments, company branding (logos and colors), and packaging formats, ensuring clients' requirements are met precisely.

Export Potency

Korean manufacturers prepare products with comprehensive certifications, technical documentation, and traceability, facilitating smooth customs clearance and compliance in various overseas markets.

Advantages of OEM Partnerships with Korean Kwikstage Manufacturers for Foreign Brands

OEM collaborations offer multiple competitive advantages:

- Cost Efficiency: Direct cooperation with Korean factories often avoids unnecessary intermediaries, providing better price-quility ratios.

- Tailored Product Solutions: Flexibility in design, finish, branding, and packaging allows foreign brands to cater specifically to target market needs.

- Quality Assurance: Korean factories implement rigorous quality management, with consistent supervision over raw materials, fabrication, and final inspection.

- Technical and After-Sales Support: OEM partners benefit from installation guidance, defect management, and ongoing customer service ensuring smooth project execution.

- Timely Delivery and Scalability: Korean manufacturers' production systems can scale quickly to handle large or rapid orders, fulfilling urgent or large infrastructure project demands.

Conclusion

South Korea's Kwikstage scaffolding manufacturers and suppliers represent a technologically advanced, quality-focused industry with strong export capabilities and flexible OEM services. Pioneering companies such as Dong Myung Industrial, Steel Korea, Seobo Industrial, and Hory Korea exemplify the industry's commitment to producing robust, corrosion-resistant, and customizable Kwikstage scaffolding systems meeting international safety standards.

Their competitive pricing, scalable production, and dedication to technical support make them ideal partners for foreign brands, wholesalers, and producers seeking reliable OEM suppliers. By combining Korea's manufacturing excellence with OEM service flexibility, these companies ensure access to top-tier scaffold systems that meet stringent safety and performance requirements globally, supporting projects from small renovations to large-scale infrastructure developments.

FAQ

1. What distinguishes Korean Kwikstage scaffolding manufacturers and suppliers?

Korean manufacturers integrate cutting-edge production technologies, strict quality control, and a customer-centric OEM approach. They focus on premium materials, rigorous corrosion resistance, product customization, and full compliance with global safety and quality standards.

2. How is the quality of Kwikstage scaffolding ensured by Korean manufacturers?

Quality is monitored through comprehensive systems that include premium steel sourcing, automated precision welding, standardized hot-dip galvanization, adherence to ISO certifications, and multiple inspection checkpoints during production.

3. Can Korean Kwikstage scaffolding be customized for specific international projects?

Yes. OEM manufacturers in Korea provide extensive customization including length and diameter adjustments, finishing options such as galvanization or powder coating, company-specific branding, and specialized packaging tailored to client or regional needs.

4. What are the primary materials used in Korean Kwikstage scaffolding?

The main materials are high-grade, cold-formed steel pipes treated with hot-dip galvanization for corrosion resistance. Additional powder coatings or paint finishes are applied in some cases for aesthetics and extended durability.

5. How do OEM collaborations with Korean manufacturers benefit foreign brands or wholesalers?

Such partnerships offer competitively priced, high-quality scaffolding systems customized to meet specific market demands backed by reliable Korean manufacturing standards and robust after-sales support, facilitating cost-effective and compliant supply.