Content Menu

● What is Ringlock Scaffolding?

● Key Features of Ringlock Scaffolding

● The Indian Market for Ringlock Scaffolding

● Leading Ringlock Scaffolding Manufacturers and Suppliers in India

>> 1. Jaysons Enterprises (Ludhiana, Punjab)

>> 2. Rcon Engineering (Rajkot, Gujarat)

>> 3. Scaff Engineers (Hyderabad, Telangana)

>> 4. Delite Industries (Jalandhar, Punjab)

>> 5. Acme Forgings (Jalandhar, Punjab)

>> 6. Finomax Scaffolding Pvt Ltd

>> 7. Schach Engineers Pvt Ltd

>> 8. The Fasteners House (Maharashtra)

● Manufacturing and Quality Assurance of Ringlock Scaffolding in India

● Applications of Ringlock Scaffolding in India

>> Environmental and Safety Considerations

>> Technological Innovations in Ringlock Scaffolding

● Advantages of Partnering with Experienced Ringlock Scaffolding Manufacturers and Suppliers

● Conclusion

● FAQ

>> 1. What are the main components of Ringlock scaffolding?

>> 2. How does the Ringlock locking mechanism work?

>> 3. What materials are used in manufacturing Ringlock scaffolding?

>> 4. Can Ringlock scaffolding be customized for different projects?

>> 5. Are there local Ringlock scaffolding suppliers in India?

Ringlock scaffolding has become an essential component in India's rapidly expanding construction sector. Known for its modular design, high load capacity, and ease of assembly, Ringlock scaffolding is widely used across residential, commercial, infrastructure, and industrial projects. As a Chinese scaffolding materials manufacturer providing OEM services to foreign brand owners, wholesalers, and producers, we understand the importance of partnering with reliable Ringlock scaffolding manufacturers and suppliers to meet the growing demands of the Indian market. This article offers a comprehensive overview of the top Ringlock scaffolding manufacturers and suppliers in India, highlighting their product quality, manufacturing processes, and the advantages of Ringlock scaffolding for diverse applications.

What is Ringlock Scaffolding?

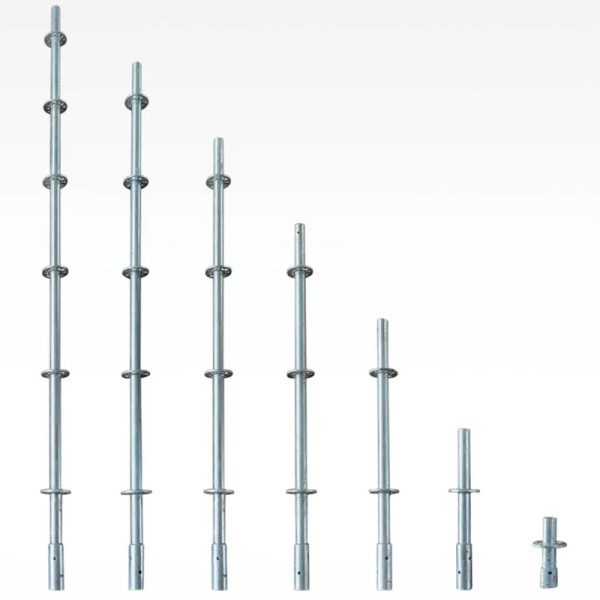

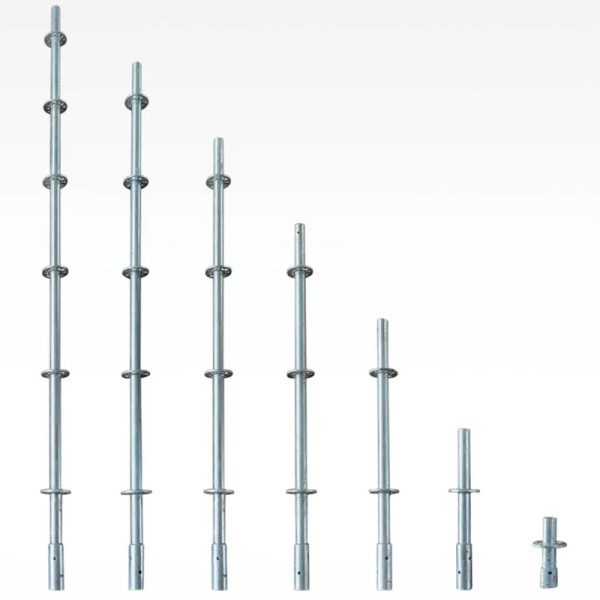

Ringlock scaffolding is a modular access scaffolding system characterized by a unique rosette (ring) and wedge-head locking mechanism. This design allows for quick, bolt-free assembly by hammering wedge-head connectors into rosette plates welded on vertical standards. The system mainly consists of vertical standards, horizontal ledgers, diagonal braces, base collars, and joint pins, typically fabricated from high-strength galvanized steel to ensure durability, corrosion resistance, and safety.

Key Features of Ringlock Scaffolding

- Modular and Flexible Design: The rosette connection allows up to eight connections per node, enabling flexible configurations for complex and irregular structures.

- High Load Capacity: Constructed from high tensile steel such as Q345 or Q355, Ringlock scaffolding supports heavy loads and complies with international safety standards.

- Rapid Assembly and Disassembly: The wedge-head locking system enables quick and secure connections, reducing labor time and costs.

- Durability and Reusability: Hot-dip galvanization protects components from corrosion, extending service life beyond 15 years and allowing multiple reuse cycles.

- Wide Application Range: Suitable for residential, commercial, infrastructure, industrial, and event staging projects.

The Indian Market for Ringlock Scaffolding

India's construction industry is among the fastest-growing sectors worldwide, driven by urbanization, infrastructure development, and industrial expansion. This growth has significantly increased the demand for high-quality scaffolding systems that ensure safety, efficiency, and adaptability. Ringlock scaffolding has emerged as a preferred solution due to its modularity, strength, and ease of use.

Indian contractors and developers rely heavily on Ringlock scaffolding for projects ranging from high-rise buildings in metropolitan cities like Mumbai and Delhi to large infrastructure projects such as highways, bridges, and power plants. The system's versatility allows it to adapt to India's diverse climatic conditions and architectural requirements.

Leading Ringlock Scaffolding Manufacturers and Suppliers in India

India is home to numerous reputable Ringlock scaffolding manufacturers and suppliers. Many collaborate with Chinese OEM manufacturers to maintain high product quality and competitive pricing.

1. Jaysons Enterprises (Ludhiana, Punjab)

Jaysons Enterprises is a trusted manufacturer and supplier of Ringlock scaffolding components, including rosettes, diagonal braces, and standards. They specialize in hot-dip galvanized mild steel products that meet stringent quality standards. Their products are widely used in building and construction projects across India.

2. Rcon Engineering (Rajkot, Gujarat)

Rcon Engineering is a verified exporter and manufacturer of Ringlock scaffolding systems. They offer a comprehensive range of components fabricated from mild steel with galvanized finishes, catering to both domestic and international markets.

3. Scaff Engineers (Hyderabad, Telangana)

Scaff Engineers provides hot-dip galvanized iron braces and other scaffolding components. Their products are known for durability and compliance with safety standards, serving the construction industry extensively.

4. Delite Industries (Jalandhar, Punjab)

Delite Industries manufactures stainless steel and mild steel Ringlock scaffolding components, including silver rosettes and braces. Their products are widely used in industrial and commercial construction projects.

5. Acme Forgings (Jalandhar, Punjab)

Acme Forgings specializes in stainless steel rosettes and other precision components essential for Ringlock scaffolding systems. Their products emphasize strength and reliability.

6. Finomax Scaffolding Pvt Ltd

Finomax is renowned for producing high-quality Ringlock scaffolding systems in India. They operate their own steel tube rolling mill, enabling customized tube lengths and timely delivery. Finomax products are widely used in infrastructure, renovation, and maintenance projects.

7. Schach Engineers Pvt Ltd

Schach Engineers is a leading manufacturer, supplier, and exporter of Ringlock scaffolding systems across India. They focus on delivering products made with premium materials and adhering to international standards.

8. The Fasteners House (Maharashtra)

The Fasteners House is a well-known supplier and exporter of Ringlock scaffolding systems across multiple Indian cities. They offer a wide range of components to meet diverse project demands.

Manufacturing and Quality Assurance of Ringlock Scaffolding in India

Manufacturing Ringlock scaffolding involves stringent processes to ensure safety, durability, and compliance:

- Material Selection: High tensile steel pipes (Q345 or Q355) with an outer diameter of 48.3mm and wall thickness ranging from 3.0mm to 4.0mm are standard.

- Welding: Automated welding machines attach rosette plates to vertical standards with high precision and strength.

- Galvanization: Hot-dip galvanization applies a zinc coating of at least 60µm, protecting against rust and corrosion, essential for India's varied climatic conditions.

- Quality Inspection: Components undergo dimensional checks, weld integrity tests, and coating thickness measurements.

- Packaging and Delivery: Components are securely packed to prevent damage during transit and delivered promptly to meet project timelines.

Indian manufacturers often comply with international standards such as EN 12810 and EN 12811 and maintain ISO 9001 quality management certification.

Applications of Ringlock Scaffolding in India

Ringlock scaffolding's modularity and strength make it suitable for a wide range of applications in India:

- Building Construction: Used extensively for façade works, plastering, painting, and structural support in residential and commercial buildings.

- Infrastructure Projects: Ideal for bridges, tunnels, highways, and large-scale civil engineering projects.

- Industrial Maintenance: Supports equipment installation, inspection, and repair in factories, refineries, and power plants.

- Event Staging: Provides safe, quick-to-assemble platforms for concerts, exhibitions, and other temporary structures.

- Temporary Shoring: Used for excavation support and temporary load-bearing structures.

Environmental and Safety Considerations

India's diverse climate, ranging from humid tropical to arid desert conditions, poses challenges for scaffolding durability. Ringlock scaffolding's hot-dip galvanized coating is critical in providing corrosion resistance, especially in coastal and industrial areas. The modular design also facilitates easy inspection and maintenance, ensuring ongoing compliance with safety standards.

Safety regulations enforced by Indian authorities, including the Bureau of Indian Standards (BIS) and the Directorate General of Mines Safety (DGMS), require scaffolding systems to meet stringent quality and safety norms. Ringlock scaffolding systems manufactured and supplied by certified companies comply with these regulations, providing secure and reliable working platforms.

Technological Innovations in Ringlock Scaffolding

Recent technological advancements have enhanced the efficiency and safety of Ringlock scaffolding systems. Innovations include the use of higher-strength steel alloys, improved galvanization techniques, and digital scaffold management software that assists contractors in planning, tracking, and maintaining scaffolding structures on-site.

Leading manufacturers and suppliers in India are increasingly adopting these technologies to offer clients not only superior physical products but also integrated solutions that optimize scaffold usage, safety monitoring, and project management.

Advantages of Partnering with Experienced Ringlock Scaffolding Manufacturers and Suppliers

Choosing the right manufacturer or supplier is vital for project success. Experienced partners provide:

- Customization: Tailored scaffolding solutions to meet unique project specifications.

- Technical Support: Engineering design, on-site consultation, and after-sales service.

- Compliance: Products that meet local and international safety and quality standards.

- Competitive Pricing: Cost-effective solutions without compromising quality.

- Reliable Delivery: Efficient logistics to ensure timely supply and project continuity.

Our OEM services emphasize close collaboration with clients to develop scaffolding systems that integrate seamlessly into their supply chains and branding.

Conclusion

Ringlock scaffolding is a versatile, safe, and cost-effective solution for India's expanding construction industry. Whether sourced from local manufacturers or trusted Chinese OEM suppliers, its modular design and robust steel components offer unmatched adaptability and durability. For foreign brand owners, wholesalers, and producers aiming to serve the Indian market, partnering with experienced Ringlock scaffolding manufacturers and suppliers ensures high-quality products tailored to diverse project needs. Investing in Ringlock scaffolding enhances worker safety, optimizes project efficiency, and reduces overall costs, making it the ideal choice for modern construction projects in India.

FAQ

1. What are the main components of Ringlock scaffolding?

Ringlock scaffolding consists of vertical standards with rosettes, horizontal ledgers, diagonal braces, base collars, and joint pins. Accessories include staircases, catwalks, and guardrails.

2. How does the Ringlock locking mechanism work?

The rosette plate welded onto the standards features multiple holes. Ledgers and braces lock into these holes using wedge-head connectors, hammered into place for secure, bolt-free connections.

3. What materials are used in manufacturing Ringlock scaffolding?

High tensile steel pipes (Q345 or Q355) are used, with hot-dip galvanization applied to prevent corrosion and extend product lifespan, typically up to 15 years.

4. Can Ringlock scaffolding be customized for different projects?

Yes, the modular design allows flexible configurations and the addition of various accessories to meet specific height, load, and shape requirements.

5. Are there local Ringlock scaffolding suppliers in India?

Yes, India has numerous local manufacturers and suppliers such as Jaysons Enterprises, Finomax Scaffolding, and Schach Engineers, many of which collaborate with Chinese OEM manufacturers to ensure quality and supply.