Content Menu

● Introduction to Ringlock Scaffolding

● Leading Ringlock Scaffolding Manufacturers in Russia

>> 1. SOYUZ

>> 2. POLATL

>> 3. BAUMAK

>> 4. NOVAYA VYSOTA

>> 5. PROMSTROIKONTRAKT and TD PIONER

● Ringlock Scaffolding Manufacturing Process and Quality Assurance

● Advantages of Ringlock Scaffolding Systems

● Applications of Ringlock Scaffolding in Russia

● OEM Services for Ringlock Scaffolding

● Conclusion

● FAQ

>> 1. What is Ringlock scaffolding, and why is it popular in Russia?

>> 2. Who are the leading Ringlock scaffolding manufacturers in Russia?

>> 3. What manufacturing technologies are used for Ringlock scaffolding in Russia?

>> 4. How does the Ringlock system improve construction safety?

>> 5. Can foreign companies source Ringlock scaffolding through OEM services?

Ringlock scaffolding is a modular, versatile, and highly efficient system widely used in construction projects worldwide. In Russia, the demand for reliable Ringlock scaffolding manufacturers and suppliers has grown significantly due to the country's expanding infrastructure and industrial development. This article explores the top Ringlock scaffolding manufacturers and suppliers in Russia, highlighting their products, manufacturing capabilities, and services.

Introduction to Ringlock Scaffolding

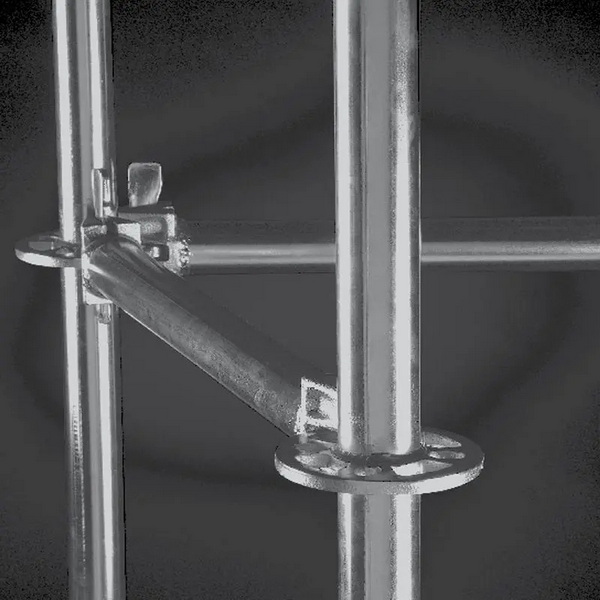

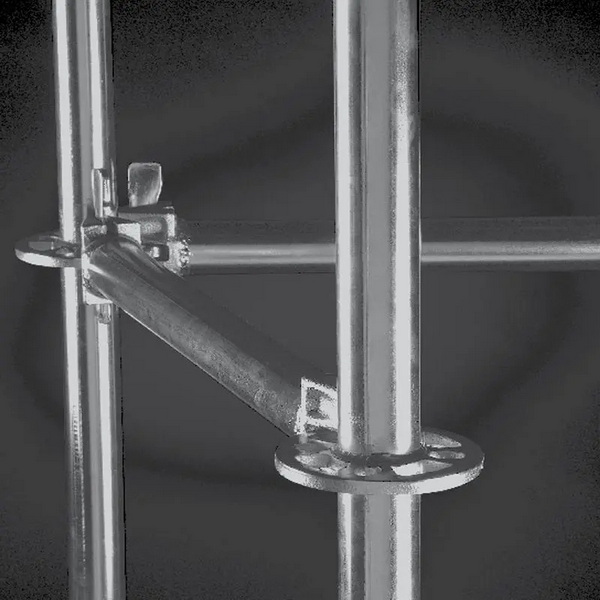

Ringlock scaffolding is a modular system characterized by a rosette (ring) and wedge-head locking mechanism, which allows for quick assembly and disassembly. It is favored for its flexibility, load capacity, and safety features, making it suitable for various construction applications, including industrial platforms, circular scaffolding, and facade support.

The system's modularity enables it to adapt to complex structures, providing safe access and work areas at heights. It is cost-effective by optimizing material usage according to load requirements and is widely used in Russia's construction and industrial sectors.

Leading Ringlock Scaffolding Manufacturers in Russia

1. SOYUZ

SOYUZ is recognized as the number one scaffolding manufacturer in Russia, specializing in wedge-shaped and Ringlock scaffolding systems. The company boasts advanced manufacturing facilities, including high-precision foundry manufacturing, automatic welding stations, roller forming lines, and laser cutting shops, ensuring high-quality products with tight tolerances.

SOYUZ's scaffolding is praised for safety and reliability, with significant projects completed for major clients like Gazpromneft-MNPZ. The company also operates training centers in key industrial cities such as Mytishchi, Yekaterinburg, Blagoveshchensk, and St. Petersburg, providing skilled scaffolders for installation worldwide.

Their Ringlock system is known for fast assembly, high safety standards, and adaptability to various structural needs, including heavy circular scaffolding and self-supporting facades. SOYUZ supplies well-labeled, lightweight components (under 25kg) that are palletized for easy site delivery and use.

2. POLATL

POLATL is a major professional scaffolding manufacturer and supplier based in the Moscow region. With over 10 years of experience and more than 1500 employees, POLATL has participated in over 10,000 construction projects across Russia and Europe.

POLATL collaborates closely with SOYUZ, offering the unique Ringlock system "Soyuz," which provides safe and comfortable working environments at extreme heights, including the highest scaffolding in Europe at over 440 meters tall.

Their services include sales, rental, assembly, and worker training, emphasizing site safety and efficiency. POLATL also offers scaffolding building guidance and safety assessments for European clients.

3. BAUMAK

Located in Stavropol, BAUMAK specializes in props, cuplock scaffolding, clamps, and jack bases. While their focus is broader than just Ringlock scaffolding, they contribute to the Russian scaffolding market by providing essential accessories and components compatible with modular systems.

4. NOVAYA VYSOTA

NOVAYA VYSOTA, based in Gatchina, supplies ladders, scaffold towers, scaffolding systems, and accessories. Their products support the construction of Ringlock scaffolding structures by providing complementary equipment needed for safe and efficient work at heights.

5. PROMSTROIKONTRAKT and TD PIONER

These companies focus on the production and delivery of construction materials and equipment, including scaffolding components. PROMSTROIKONTRAKT operates in Moscow, while TD PIONER also supplies steel and metal transformation services, supporting the scaffolding industry with raw materials and dismantling services.

Ringlock Scaffolding Manufacturing Process and Quality Assurance

Modern Ringlock scaffolding manufacturers in Russia utilize advanced production technologies to ensure product quality and safety:

- High-precision laser cutting for components with 0.1 mm tolerance.

- Automatic welding stations to improve weld quality and consistency.

- Roller forming lines for stable steel deck production.

- Load and bearing capacity tests to ensure compliance with safety standards.

- Material certification and mock-up inspections before shipment.

These measures guarantee that Russian Ringlock scaffolding meets international standards and client expectations for durability and safety.

Furthermore, many manufacturers use hot-dip galvanizing to protect steel components from corrosion, significantly extending the scaffolding's service life, especially in harsh Russian climates. This process involves immersing the steel parts in molten zinc, creating a robust protective coating.

Manufacturers also emphasize the importance of traceability and documentation, providing clients with full certification packages, including material test reports and compliance certificates with standards such as EN 12810 and EN 12811, which are widely recognized in Europe and Russia.

Advantages of Ringlock Scaffolding Systems

- Modularity and Flexibility: Easily adapts to complex shapes and different load requirements. The rosette design allows connection at multiple angles, making it ideal for curved and irregular structures.

- Fast Assembly: The wedge and rosette locking mechanism allows quick and secure connections without the need for nuts or bolts, reducing labor time and costs.

- High Load Capacity: Suitable for heavy-duty industrial applications, including oil refineries, power plants, and large construction projects.

- Safety: Provides stable platforms with additional safety accessories such as guardrails, toe boards, and access ladders, ensuring worker protection.

- Cost Efficiency: Optimizes material usage and reduces labor costs due to faster erection and dismantling processes.

- Durability: Made from high-quality steel with protective coatings to resist corrosion, ensuring long-term usability even in demanding environments.

- Versatility: Can be used for facade scaffolding, suspended scaffolding, circular scaffolding, and heavy-duty industrial scaffolding.

- Ease of Transportation and Storage: Components are lightweight and standardized, allowing for efficient packing, shipping, and storage.

The Ringlock system's versatility makes it the preferred choice for many Russian construction companies, especially for projects requiring rapid setup and dismantling, such as bridge construction, stadiums, and industrial maintenance.

Applications of Ringlock Scaffolding in Russia

Ringlock scaffolding is extensively used across various sectors in Russia:

- Industrial Plants: For maintenance and construction of oil refineries, chemical plants, and power stations, where complex and heavy-duty scaffolding is essential.

- Infrastructure Projects: Bridges, tunnels, and highways benefit from the system's adaptability and load capacity.

- Residential and Commercial Buildings: Facade scaffolding and temporary platforms for construction and renovation.

- Event Staging: Temporary stages and platforms for concerts and public events.

- Shipbuilding and Offshore Platforms: The system's corrosion resistance and modularity are advantageous in marine environments.

The ability to create self-supporting structures and circular scaffolding is particularly valuable in Russia's industrial sectors, where large tanks and vessels require safe and stable access.

OEM Services for Ringlock Scaffolding

As a Chinese manufacturer specializing in scaffolding materials, we provide OEM services to foreign brands, wholesalers, and manufacturers. Our expertise includes:

- Customizing Ringlock scaffolding components to meet specific project requirements.

- Ensuring compliance with European and international standards such as BS EN12810 and BS EN12811.

- Offering competitive pricing without compromising quality.

- Providing timely delivery with door-to-door service.

- Supporting clients with technical guidance and after-sales service.

Our manufacturing process includes strict quality control from raw materials to final product testing, ensuring reliable and safe scaffolding systems for global markets.

We work closely with clients to develop tailored solutions, including special coatings, component sizes, and packaging methods. Our ability to integrate client branding and labeling into the products helps foreign companies maintain brand consistency while benefiting from cost-effective manufacturing.

Conclusion

Russia's scaffolding market is well-served by top manufacturers like SOYUZ and POLATL, who provide high-quality Ringlock scaffolding systems tailored to meet the demanding needs of construction and industrial projects. Their advanced manufacturing technologies, comprehensive training programs, and commitment to safety and quality make them leaders in the field. For international buyers, partnering with experienced OEM manufacturers ensures access to customizable, compliant, and cost-effective Ringlock scaffolding solutions. As infrastructure development continues in Russia, the demand for reliable Ringlock scaffolding manufacturers and suppliers remains strong, promising growth and innovation in this sector.

FAQ

1. What is Ringlock scaffolding, and why is it popular in Russia?

Ringlock scaffolding is a modular system featuring a rosette and wedge-head locking mechanism, allowing fast assembly and high load capacity. It is popular in Russia due to its flexibility, safety, and adaptability to complex construction projects.

2. Who are the leading Ringlock scaffolding manufacturers in Russia?

The leading manufacturers include SOYUZ, POLATL, BAUMAK, NOVAYA VYSOTA, and PROMSTROIKONTRAKT, with SOYUZ recognized as the number one scaffolding manufacturer in Russia.

3. What manufacturing technologies are used for Ringlock scaffolding in Russia?

Technologies include high-precision laser cutting, automatic welding stations, roller forming lines, and rigorous load and bearing capacity tests to ensure product quality and safety.

4. How does the Ringlock system improve construction safety?

Ringlock scaffolding provides stable platforms with safety accessories, quick and secure locking mechanisms, and is designed to meet international safety standards, reducing risks during assembly and use.

5. Can foreign companies source Ringlock scaffolding through OEM services?

Yes, many Chinese manufacturers offer OEM services for Ringlock scaffolding, providing customized solutions, compliance with international standards, competitive pricing, and reliable delivery for global clients.