Content Menu

● What is Ringlock Scaffolding?

● Leading Ringlock Scaffolding Manufacturers and Suppliers in Thailand

>> 1. Youfa Steel Pipe Manufacturer

>> 2. Bythai Scaffolding

>> 3. Coffral Thailand

>> 4. Gainford Construction Materials (Dongguan) Ltd.

>> 5. Wellmade Group

● Advantages of Ringlock Scaffolding Systems

● Applications of Ringlock Scaffolding in Thailand

● Quality Control and Certification

● OEM Services and Customization

● Logistics and After-Sales Support

● Conclusion

● FAQ

>> 1. What materials are used in ringlock scaffolding manufacturing?

>> 2. How does ringlock scaffolding compare to traditional tube and clamp scaffolding?

>> 3. Can ringlock scaffolding be customized for specific projects?

>> 4. What certifications should I look for when purchasing ringlock scaffolding?

>> 5. Are there rental options available for ringlock scaffolding in Thailand?

Ringlock scaffolding has become an essential modular scaffolding system widely used in construction, industrial, and maintenance projects across the globe. Known for its strength, flexibility, and rapid assembly, ringlock scaffolding is favored by contractors and engineers for projects requiring safe and efficient access solutions. Thailand, with its booming infrastructure and industrial sectors, has seen a growing demand for high quality ringlock scaffolding systems. This article explores the top ringlock scaffolding manufacturers and suppliers in Thailand, highlighting their products, services, and unique advantages for international buyers seeking OEM partnerships.

What is Ringlock Scaffolding?

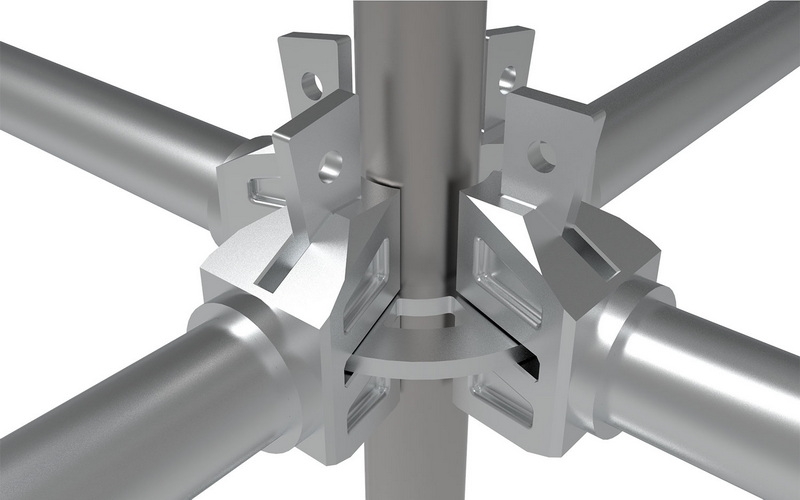

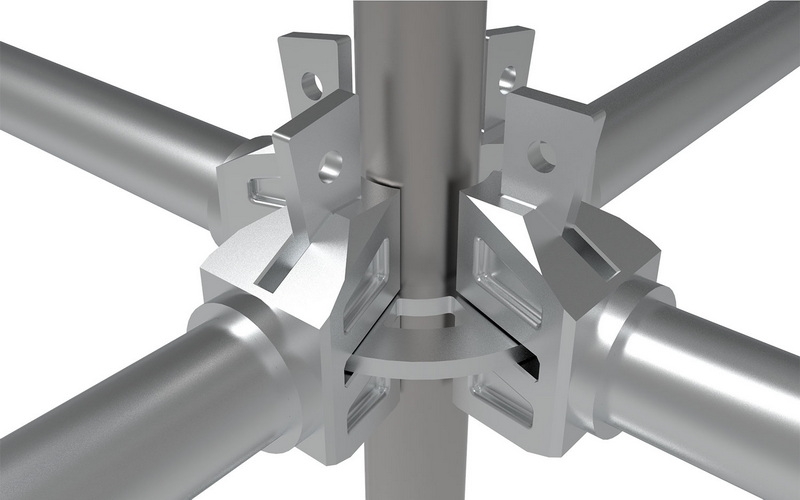

Ringlock scaffolding is a modular system characterized by vertical standards with rosettes (rings) and horizontal ledgers that connect via wedge pins. This design allows quick assembly and disassembly, making it highly adaptable to complex structures and various load requirements. The system is widely used in civil engineering, petrochemical plants, energy sectors, and large-scale infrastructure projects due to its robustness and safety features.

The ringlock system's core component is the rosette, a circular disc with multiple slots welded onto the vertical standard. This rosette enables the horizontal and diagonal components to connect securely at various angles, providing unmatched flexibility compared to traditional scaffolding systems. The wedge pins lock the components firmly in place, ensuring stability and safety on-site.

Leading Ringlock Scaffolding Manufacturers and Suppliers in Thailand

1. Youfa Steel Pipe Manufacturer

Youfa Steel Pipe Manufacturer is a professional Chinese company providing ringlock scaffolding products customized for the Thai market. They offer OEM services, wholesale options, and private label manufacturing, ensuring tailored solutions for foreign brands, wholesalers, and producers. Their product range includes galvanized steel pipes, pipe fittings, and stainless steel pipes, all integral to ringlock scaffolding systems. Youfa emphasizes quality service and timely responses, catering to clients who prioritize reliability over the lowest price.

Youfa's manufacturing process incorporates advanced welding techniques and strict quality control measures. Their hot-dip galvanizing process ensures corrosion resistance, which is vital for scaffolding used in Thailand's humid climate. Additionally, Youfa offers flexible packaging and shipping options, including FOB and CIF, to accommodate international buyers' logistics requirements.

2. Bythai Scaffolding

Bythai Scaffolding is a Thai-based manufacturer and exporter specializing in ringlock scaffolding, frame systems, shoring props, and accessories. With over 10 years of experience, they provide comprehensive scaffolding solutions compliant with EN12811 and BS standards, trusted in over 50 countries. Their products feature high-strength steel with corrosion-resistant coatings, ensuring durability for industrial and commercial projects. Bythai offers cost-efficient sourcing and a one-stop procurement service, making them a preferred supplier for large-scale construction projects in Thailand.

Bythai's commitment to innovation is evident in their continuous product development and customization capabilities. They provide engineering support to help clients design scaffolding solutions tailored to specific project requirements. Their after-sales service includes on-site technical assistance and training, which is crucial for ensuring safe scaffold erection and dismantling.

3. Coffral Thailand

Coffral Thailand focuses on industrial ringlock scaffold systems, offering full packages including engineering services and skilled scaffolders. Their industrial scaffolding solutions cater to heavy-duty applications, providing superior safety and performance. Coffral is known for delivering turnkey scaffold systems that support complex industrial environments, such as petrochemical and manufacturing plants.

Coffral's expertise extends beyond manufacturing to project management, helping clients optimize scaffold design for efficiency and cost savings. Their team of engineers uses 3D modeling software to simulate scaffold structures, ensuring compliance with safety regulations and minimizing material waste.

4. Gainford Construction Materials (Dongguan) Ltd.

Gainford Construction Materials, based in China but serving the Thai market, supplies ringlock scaffolding systems made from hot-dipped galvanized steel pipes and modular components assembled with wedge connectors. Their ringlock system is modular, designed to reduce labor costs while meeting safety and maintenance standards. Gainford offers rental services in Thailand, providing flexible options for contractors needing temporary scaffolding solutions.

Gainford's rental service is particularly attractive for short-term projects or companies looking to reduce capital expenditure. They maintain a large inventory of scaffolding components, allowing quick delivery and setup. Their maintenance team regularly inspects and refurbishes rental equipment to meet safety standards.

5. Wellmade Group

Wellmade Group is a renowned Chinese manufacturer exporting ringlock scaffolding to over 60 countries, including Thailand. They are ISO9001 certified and CE certified, ensuring high-quality manufacturing standards. Wellmade's ringlock scaffolding is tested for tensile strength, welding quality, and load capacity, making it suitable for demanding projects such as bridges, tunnels, and oil and gas facilities. They provide tailored OEM services, on-time delivery, and door-to-door shipping, supporting foreign brand owners and wholesalers with competitive pricing and technical expertise.

Wellmade's extensive R&D capabilities enable them to innovate new scaffolding components that improve ease of use and safety. Their global logistics network ensures smooth export processes, reducing lead times for clients in Thailand and beyond.

Advantages of Ringlock Scaffolding Systems

- Speed and Efficiency: Modular design allows quick assembly and dismantling, saving labor time. The wedge locking mechanism eliminates the need for bolts and nuts, speeding up construction.

- Flexibility: Adjustable components fit various structural shapes and load requirements. The rosette design enables connections at multiple angles, accommodating complex architectural forms.

- Safety: Robust steel materials and tested connections ensure high load-bearing capacity. The system meets international safety standards, reducing accident risks.

- Durability: Galvanized coatings resist corrosion, extending service life in harsh environments. This is especially important in Thailand's tropical climate.

- Cost-Effectiveness: Reduced labor and maintenance costs compared to traditional scaffolding. The modular nature allows reuse across multiple projects, maximizing ROI.

Applications of Ringlock Scaffolding in Thailand

Ringlock scaffolding is widely used in various sectors across Thailand, including:

- Construction: High-rise buildings, residential complexes, and commercial centers utilize ringlock scaffolding for facade access, formwork support, and temporary structures.

- Industrial Maintenance: Petrochemical plants, refineries, and power stations require safe scaffolding for inspection, repair, and upgrades.

- Infrastructure Projects: Bridges, tunnels, and highways benefit from the system's adaptability and load capacity.

- Events and Stages: Temporary platforms and stages for concerts and exhibitions often use ringlock scaffolding due to its quick setup and dismantling.

- Shipbuilding and Offshore: The marine industry uses ringlock scaffolding for ship repairs and offshore platform maintenance, where safety and corrosion resistance are critical.

Quality Control and Certification

When sourcing ringlock scaffolding from manufacturers and suppliers in Thailand or abroad, it is essential to verify quality and certification. Reliable manufacturers adhere to international standards such as:

- ISO9001: Quality management system certification ensuring consistent product quality.

- CE Marking: Compliance with European safety standards.

- EN12810 and EN12811: European standards specific to scaffolding design and performance.

- ASTM and BS: American and British standards for material strength and safety.

Manufacturers often provide test reports on tensile strength, weld quality, and load capacity. These certifications and tests guarantee that the scaffolding components meet rigorous safety and performance requirements.

OEM Services and Customization

Many ringlock scaffolding manufacturers and suppliers in Thailand offer OEM (Original Equipment Manufacturer) services, allowing foreign brands and wholesalers to customize products under their own brand names. Customization options include:

- Dimensions: Adjusting pipe diameters, thicknesses, and lengths to suit specific project needs.

- Coatings: Options such as hot-dip galvanizing, powder coating, or painting for enhanced corrosion resistance and aesthetics.

- Branding: Custom logos, packaging, and labeling for brand recognition.

- Accessories: Tailored components like base plates, couplers, and safety fittings.

OEM partnerships enable companies to differentiate their product offerings and meet local market demands effectively.

Logistics and After-Sales Support

Efficient logistics and after-sales support are critical when dealing with ringlock scaffolding manufacturers and suppliers, especially for international buyers. Key considerations include:

- Shipping Options: FOB, CIF, and door-to-door delivery services to streamline import processes.

- Inventory Management: Suppliers with large stockpiles can fulfill urgent orders quickly.

- Technical Support: On-site training, installation guidance, and safety consultations help clients maximize scaffold performance.

- Warranty and Maintenance: Reliable manufacturers offer warranties and maintenance services to ensure product longevity and safety.

Conclusion

Thailand's growing construction and industrial sectors demand reliable and high-performance scaffolding solutions. Ringlock scaffolding, with its modular design, safety features, and efficiency, is an ideal choice for these applications. Leading manufacturers and suppliers such as Youfa Steel Pipe Manufacturer, Bythai Scaffolding, Coffral Thailand, Gainford Construction Materials, and Wellmade Group offer comprehensive products and services tailored to meet the needs of foreign brands, wholesalers, and producers. Their commitment to quality, customization, and timely delivery makes them trusted partners in the Thai market. By choosing reputable ringlock scaffolding manufacturers and suppliers, businesses can ensure project success with safe, durable, and cost-effective scaffolding systems.

FAQ

1. What materials are used in ringlock scaffolding manufacturing?

Ringlock scaffolding is typically made from high-strength steel, often galvanized to resist corrosion. Some components may also be made from aluminum for lighter applications.

2. How does ringlock scaffolding compare to traditional tube and clamp scaffolding?

Ringlock scaffolding offers faster assembly, greater flexibility, and higher load capacity due to its modular rosette and wedge locking system, making it more efficient and safer for large projects.

3. Can ringlock scaffolding be customized for specific projects?

Yes, many manufacturers, including those serving Thailand, provide OEM services allowing customization of dimensions, coatings, and branding to meet client requirements.

4. What certifications should I look for when purchasing ringlock scaffolding?

Look for ISO9001 factory certification, CE marking, and compliance with standards such as EN12810, ASTM, and BS to ensure quality and safety.

5. Are there rental options available for ringlock scaffolding in Thailand?

Yes, companies like Gainford offer rental services in Thailand, providing flexible and cost-effective solutions for temporary scaffolding needs.