Content Menu

● What is Ringlock Scaffolding?

● Key Features of Ringlock Scaffolding

● The Growing Demand for Ringlock Scaffolding in Vietnam

● Leading Ringlock Scaffolding Manufacturers and Suppliers in Vietnam

>> 1. LIPHOCO

>> 2. Sucoot Co., Ltd.

>> 3. Vietnamese Local Manufacturers and Suppliers

>> 4. Chinese Manufacturers Serving Vietnam Market

● Advantages of Choosing Vietnamese Ringlock Scaffolding Manufacturers

● Ringlock Scaffolding Components and Their Functions

● Applications of Ringlock Scaffolding in Vietnam

● Industry Trends and Innovations

● Conclusion

● FAQ

>> 1. What materials are used in ringlock scaffolding manufacturing?

>> 2. How does the ringlock system ensure safety and stability?

>> 3. Can ringlock scaffolding be customized for specific projects?

>> 4. What are the main applications of ringlock scaffolding?

>> 5. How does Vietnamese ringlock scaffolding compare to products from other countries?

Ringlock scaffolding is a versatile, modular, and highly efficient scaffolding system widely used in construction projects worldwide. Vietnam, as a rapidly developing country with a booming construction industry, has become a significant market and manufacturing hub for ringlock scaffolding. This article explores the top ringlock scaffolding manufacturers and suppliers in Vietnam, highlighting their products, capabilities, and services.

What is Ringlock Scaffolding?

Ringlock scaffolding, also known as ring system scaffolding, is a modular scaffolding solution characterized by a unique rosette (ring) and wedge-head locking mechanism. This design allows for quick assembly and disassembly, exceptional load-bearing capacity, and adaptability to various construction needs such as shoring, facade access, and staging.

Key Features of Ringlock Scaffolding

- Modular design: Components like vertical standards, ledgers, diagonal braces, base collars, and steel planks can be assembled in multiple configurations.

- High load capacity: Suitable for heavy-duty construction projects.

- Fast and safe assembly: The wedge and rosette locking system ensures secure connections.

- Durability: Made from high-quality steel grades such as Q235 and Q345, often hot-dip galvanized for corrosion resistance.

- Versatility: Can be used on uneven terrain and in complex structures.

- Compliance with international standards: Such as EN 12810, BS 1139, and OSHA regulations, ensuring safety and reliability.

The Growing Demand for Ringlock Scaffolding in Vietnam

Vietnam's rapid urbanization, infrastructure development, and industrial expansion have driven the demand for advanced scaffolding solutions. Ringlock scaffolding, with its modularity and efficiency, has become the preferred choice for many large-scale projects including high-rise buildings, bridges, power plants, and offshore platforms.

Vietnam's strategic location in Southeast Asia also makes it an ideal manufacturing hub for scaffolding products destined for regional and global markets. The government's focus on infrastructure investment and foreign direct investment (FDI) further supports the growth of scaffolding manufacturers and suppliers in the country.

Leading Ringlock Scaffolding Manufacturers and Suppliers in Vietnam

Vietnam hosts several reputable companies specializing in manufacturing and supplying ringlock scaffolding systems. These companies serve both domestic and international markets, offering OEM services and customized solutions.

1. LIPHOCO

Established in 2014, LIPHOCO specializes in manufacturing and exporting ringlock scaffolding with 100% investment from one of Italy's largest scaffolding manufacturers. LIPHOCO has successfully partnered with major Vietnamese construction contractors such as Newtecons and Hoa Binh Group. The company also expanded into mechanical processing to serve global clients in the US, Mexico, Europe, and Japan while maintaining a strong focus on ringlock scaffolding production for Vietnam and exports to Europe.

LIPHOCO's product range includes vertical standards, ledgers, diagonal braces, base plates, steel planks, stairways, and accessories. Their manufacturing process emphasizes quality control, using advanced welding techniques and hot-dip galvanizing to ensure corrosion resistance and long service life.

2. Sucoot Co., Ltd.

Sucoot is a well-known manufacturer with nearly four decades of experience in ringlock scaffolding. With ISO 9001-certified factories in Taiwan and China, Sucoot offers high-quality ringlock scaffolding systems compliant with EN 12810-1 and ANSI/ASSE A10.8 standards. They provide robust, modular scaffolding solutions with excellent load-bearing capacity and fast installation features.

Sucoot's technical team provides comprehensive support, including design consultation, structural analysis, and onsite training. Their products are widely used in infrastructure, industrial, and commercial projects across Asia and beyond.

3. Vietnamese Local Manufacturers and Suppliers

Vietnam has a variety of local scaffolding manufacturers and suppliers, including:

- Vietnam Cuong Hung Scaffolding: Located in Ho Chi Minh City, they produce scaffolding and accessories, including concrete mixers. Their product line is tailored to meet the needs of local construction companies with competitive pricing and reliable quality.

- Peri Formwork & Scaffolding Vietnam: A branch of the global Peri Group, offering full construction process solutions including formwork, scaffolding systems, and panels. Peri's presence in Vietnam brings international standards and innovative technologies to the local market.

- Nguyen Khang Co. Ltd: Specializes in frame scaffolding, standards, braces, and steel boards. They focus on providing durable and safe scaffolding products for various construction applications.

- Saki Corp: Established in 2003, Saki Corp produces scaffolding products meeting BS 1339, OSHA, and EN standards and offers leasing services for smaller projects. Their flexible rental options make them a popular choice for contractors with short-term needs.

4. Chinese Manufacturers Serving Vietnam Market

Many Chinese manufacturers provide high-quality ringlock scaffolding to the Vietnamese market, offering OEM and ODM services. For example, Tuopeng Scaffold manufactures ringlock scaffolding components with steel grades Q235 and Q345, featuring hot-dip galvanization and powder coating. Their product range includes verticals, ledgers, diagonal braces, base collars, steel planks, stairways, and more. These manufacturers emphasize reliability, durability, and compatibility with existing systems.

Chinese suppliers often collaborate with Vietnamese distributors to ensure timely delivery, competitive pricing, and after-sales service. This cooperation strengthens the supply chain and supports Vietnam's growing construction demands.

Advantages of Choosing Vietnamese Ringlock Scaffolding Manufacturers

- Cost-effectiveness: Competitive pricing due to local production and reduced shipping costs.

- Customization: Ability to provide OEM services tailored to client requirements.

- Quality assurance: Compliance with international standards and certifications.

- Technical support: Many suppliers offer engineering and after-sales support.

- Proximity to Southeast Asian markets: Facilitates faster delivery and better logistics.

- Sustainability initiatives: Some manufacturers have adopted environmentally friendly processes such as recycling steel and reducing emissions during production.

Ringlock Scaffolding Components and Their Functions

Understanding the main components of ringlock scaffolding helps appreciate its modularity and strength:

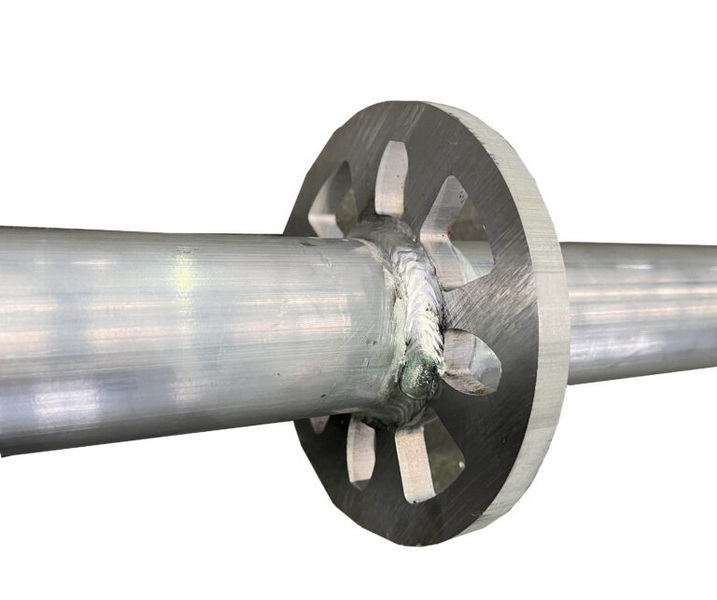

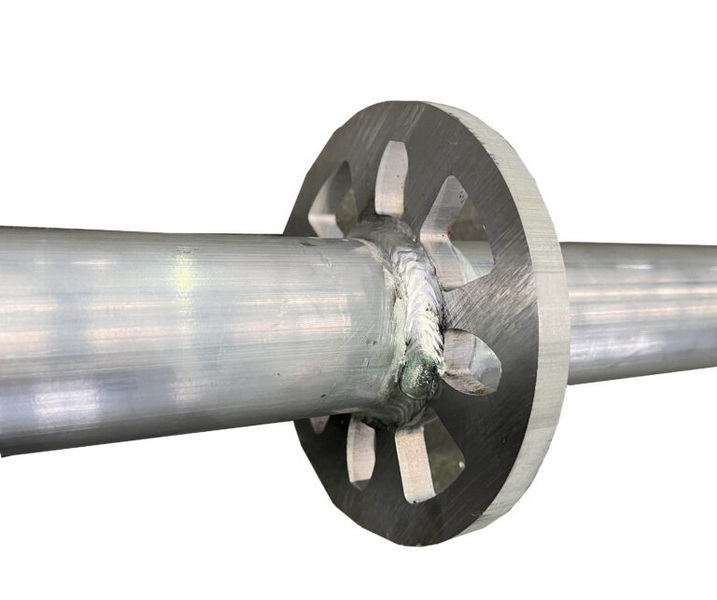

- Vertical Standards: The main vertical pipes with rosettes welded at regular intervals for connecting ledgers and braces.

- Ledgers: Horizontal pipes that connect between vertical standards, providing lateral support.

- Diagonal Braces: Pipes installed diagonally to increase the rigidity and stability of the scaffolding structure.

- Base Plates and Base Collars: Provide a stable foundation and distribute the load evenly on the ground.

- Steel Planks/Decking: Platforms where workers stand and place equipment.

- Rosettes (Rings): Circular discs with multiple slots welded on vertical standards to connect ledgers and braces using wedges.

- Wedges: Locking elements that secure ledgers and braces into the rosette slots.

This design allows for quick assembly and disassembly without the need for nuts or bolts, reducing labor costs and improving safety.

Applications of Ringlock Scaffolding in Vietnam

Ringlock scaffolding is widely used across various sectors in Vietnam:

- High-rise building construction: Provides safe access and support for workers and materials.

- Bridge and infrastructure projects: Offers strong shoring and formwork support.

- Industrial plants and factories: Used for maintenance, repair, and new installations.

- Offshore platforms and shipbuilding: Adaptable to complex shapes and uneven surfaces.

- Event staging and temporary structures: Modular design allows for flexible configurations.

The adaptability and strength of ringlock scaffolding make it indispensable in Vietnam's diverse construction landscape.

Industry Trends and Innovations

Vietnamese ringlock scaffolding manufacturers are increasingly adopting innovations to improve product quality and meet evolving market demands:

- Automation in manufacturing: Use of CNC machines and robotic welding to enhance precision and efficiency.

- Advanced coatings: Development of eco-friendly galvanizing and powder coatings to extend product lifespan.

- Digital design and BIM integration: Incorporating Building Information Modeling (BIM) to optimize scaffolding design and project management.

- Lightweight alloys and composites: Research into alternative materials to reduce weight without compromising strength.

- Rental and leasing services: Growing trend of scaffolding rental to reduce upfront costs for contractors.

These trends position Vietnam's scaffolding industry for sustainable growth and global competitiveness.

Conclusion

Vietnam has emerged as a key player in the ringlock scaffolding manufacturing and supply industry. With a mix of local expertise and international collaboration, Vietnamese manufacturers and suppliers offer high-quality, versatile, and cost-effective ringlock scaffolding solutions. Whether for domestic construction projects or export, these companies provide comprehensive services including OEM manufacturing, technical support, and compliance with global standards. Choosing Vietnamese ringlock scaffolding suppliers ensures reliability, efficiency, and excellent value for construction needs. The continued adoption of innovative manufacturing techniques and sustainable practices further enhances Vietnam's position as a trusted source for ringlock scaffolding in Southeast Asia and beyond.

FAQ

1. What materials are used in ringlock scaffolding manufacturing?

Ringlock scaffolding is primarily made from carbon steel grades Q235 and Q345, often treated with hot-dip galvanization or powder coating to enhance corrosion resistance and durability.

2. How does the ringlock system ensure safety and stability?

The system uses a rosette (ring) with multiple slots and a wedge that locks into these slots, creating secure connections that distribute loads evenly and prevent accidental disassembly.

3. Can ringlock scaffolding be customized for specific projects?

Yes, many manufacturers offer OEM services, allowing clients to specify dimensions, surface treatments, and component types to suit their project needs.

4. What are the main applications of ringlock scaffolding?

Ringlock scaffolding is used for heavy-duty shoring, facade access, staging, bridge construction, and maintenance work due to its high load capacity and modularity.

5. How does Vietnamese ringlock scaffolding compare to products from other countries?

Vietnamese manufacturers provide competitive pricing and quality comparable to international standards, supported by local expertise and proximity to regional markets, making them a preferred choice for many construction companies.