Content Menu

● Introduction to Scaffolding Aluminum Planks Manufacturers and Suppliers in America

● Why Choose American Scaffolding Aluminum Planks Manufacturers and Suppliers?

● Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in America

>> 1. Advanced Ladders and Scaffold

>> 2. Penn Tool Co.

>> 3. Ver Sales, Inc.

>> 4. Universal Manufacturing Corp.

>> 5. Lynn Ladder & Scaffolding Co., Inc.

>> 6. MSC Industrial Supply Co.

>> 7. Associated Scaffolding Co., Inc.

>> 8. Upright Scaffold USA, LLC

>> 9. Scaffold Depot

>> 10. Layher North America

● Key Features of American Scaffolding Aluminum Planks

● Manufacturing Technologies and Quality Assurance

● Applications of Scaffolding Aluminum Planks

● OEM Services and Customization

● Logistics and Export Solutions

● Innovations in Scaffolding Aluminum Planks

● Conclusion

● FAQ

>> 1. What are the main advantages of scaffolding aluminum planks over wood or steel?

>> 2. Do American manufacturers offer OEM and private label services?

>> 3. Are American scaffolding aluminum planks compliant with global safety standards?

>> 4. Can I order custom sizes or special features for my project?

>> 5. How do American suppliers ensure product quality and safety?

America is home to some of the world's most advanced scaffolding aluminum planks manufacturers and suppliers, serving a diverse range of construction, industrial, and OEM clients. These companies are recognized for their commitment to safety, product innovation, and meeting the highest industry standards. This comprehensive article explores the leading scaffolding aluminum planks manufacturers and suppliers in America , delves into their product offerings, technologies, and OEM capabilities, and answers key questions for buyers and partners worldwide.

Introduction to Scaffolding Aluminum Planks Manufacturers and Suppliers in America

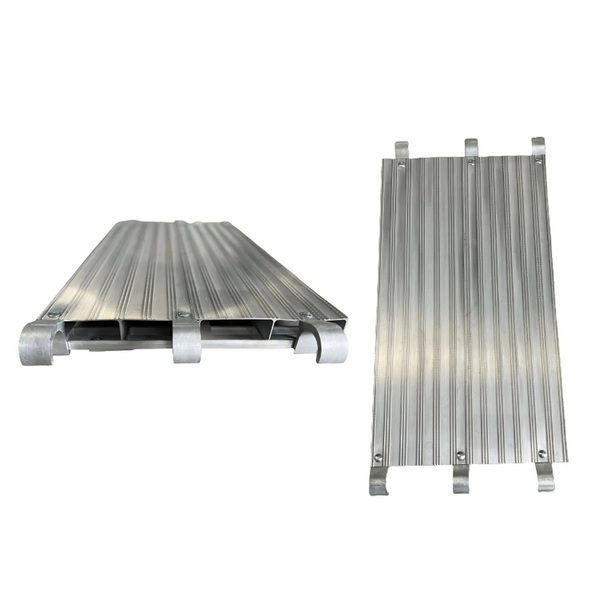

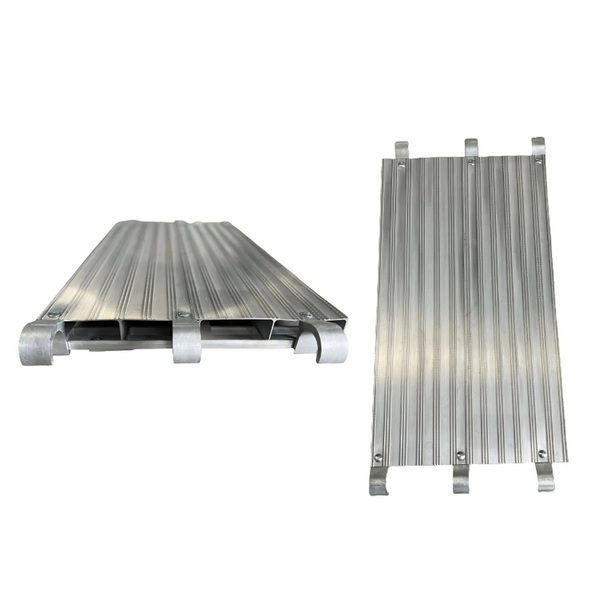

Scaffolding aluminum planks are essential components in modern construction, providing safe, lightweight, and durable platforms for workers. American manufacturers have mastered the art of producing high-performance aluminum planks that meet stringent OSHA and ANSI standards. These planks are favored for their corrosion resistance, ease of handling, and long service life, making them indispensable on job sites ranging from skyscraper construction to industrial maintenance.

The demand for scaffolding aluminum planks has grown steadily due to their superior strength-to-weight ratio compared to traditional wood or steel planks. This growth has driven American manufacturers to continuously innovate, improving safety features and manufacturing processes to meet evolving industry needs.

Why Choose American Scaffolding Aluminum Planks Manufacturers and Suppliers?

- Strict Compliance: Products adhere to rigorous OSHA and ANSI safety regulations, ensuring worker safety and legal compliance on job sites.

- Advanced Manufacturing: Use of state-of-the-art automated welding, extrusion, and anodizing processes results in consistent, high-quality products.

- Customization: OEM services allow for private labeling, custom sizing, and branding to meet specific project requirements.

- Global Reach: Many American suppliers export worldwide, supporting international brands, wholesalers, and producers with tailored solutions.

- Sustainability: Commitment to eco-friendly manufacturing processes, including the use of recycled aluminum and energy-efficient production techniques.

Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in America

1. Advanced Ladders and Scaffold

- Location: Pacific Northwest, USA

- Product Range: Aluminum planks and stages, widths from 14" to 24", lengths from 12' to 32', load capacities from 250 lbs. (single-person) to 750 lbs. (three-person)

- Features: OSHA and ANSI compliant, custom lengths available, one-year warranty, guard rail systems for enhanced safety

- Applications: Supported and suspended scaffolding systems, gangways, construction platforms

- OEM Services: Custom manufacturing for private label and specific project requirements

- Support: Fully trained staff for technical support and project consultation

2. Penn Tool Co.

- Established: 1968

- Location: USA

- Product Range: Wide and narrow span scaffolding made from aluminum, lengths from 6 to 10 ft., heights from 6 to 10 ft.

- Strengths: Made in the USA, suitable for various industries including construction, aerospace, and automotive

- OEM Capabilities: Custom manufacturing and distribution for private brands

3. Ver Sales, Inc.

- Founded: 1972

- Location: USA

- Product Range: Aluminum scaffolds for aerospace, automotive, marine, and industrial use

- Compliance: ANSI and OSHA standards

- OEM Services: Custom manufacturing and design, distribution partnerships

4. Universal Manufacturing Corp.

- Established: 1934

- Product Range: Frame scaffold, system scaffold, tube & clamp, shoring, hydraulic mast climbers, planking, custom fabricated access equipment

- Strengths: American-made, engineering support, detailed layouts, shipment scheduling

- OEM Services: Custom fabrication for OEM and private label clients

5. Lynn Ladder & Scaffolding Co., Inc.

- Founded: 1900

- Location: USA

- Product Range: Aluminum, folding, and modular scaffolding; standard and custom aluminum planks

- Features: Load capacity up to 50 lbs. per square foot, various sizes, modular frames

- OEM Services: Custom manufacturing, private labeling, and distribution

6. MSC Industrial Supply Co.

- Established: 1941

- Product Range: Aluminum and steel scaffolding, rolling and work platform systems, load capacities up to 1,000 lbs.

- Industries Served: Education, automotive, aerospace, medical, government

- OEM Services: Vendor-managed inventory, next-day delivery, custom solutions

7. Associated Scaffolding Co., Inc.

- Founded: 1947

- Product Range: Telescoping aluminum ladders and scaffold planks, lengths from 13 ft. to 26 ft., 300 lbs. capacity

- Features: Double riveted steps, push knobs, flared bottoms, same-day shipping

- OEM Services: Customization and branding for distributors

8. Upright Scaffold USA, LLC

- Established: 1947

- Product Range: Aluminum scaffolding, stairwell scaffolds, modular systems, aviation maintenance systems, walkway and bridging systems

- Features: Lightweight construction, cold-formed joints, locking brace hooks, adjustable legs

- OEM Services: Full-service design and engineering for custom solutions

9. Scaffold Depot

- Location: North America (serving USA and Canada)

- Product Range: Aluminum and plywood planks, steel planks, system scaffolding

- OEM Capabilities: Custom sizes, private labeling, export services

10. Layher North America

- Location: USA and Canada

- Product Range: Industrial and commercial scaffolding systems, including aluminum planks

- Strengths: Global brand, advanced engineering, comprehensive OEM services

Key Features of American Scaffolding Aluminum Planks

- Lightweight Construction: Aluminum planks are significantly lighter than steel or wood, reducing worker fatigue and transportation costs.

- High Load Capacity: Planks support loads ranging from 250 lbs. (single-person) to 750 lbs. (multi-person), depending on design.

- Corrosion Resistance: Anodized or powder-coated surfaces ensure long-lasting protection against rust and environmental damage.

- Versatile Applications: Suitable for supported and suspended scaffolding, gangways, and industrial platforms across various industries.

- Safety Compliance: All major manufacturers meet or exceed OSHA and ANSI standards, ensuring worker safety and regulatory compliance.

Manufacturing Technologies and Quality Assurance

American manufacturers utilize cutting-edge technologies and stringent quality control to produce top-tier scaffolding aluminum planks:

- Automated Welding: Robotic welding systems produce consistent, high-strength joints, minimizing defects and enhancing durability.

- Extrusion and Anodizing: Aluminum planks are extruded with precise dimensions and anodized to improve corrosion resistance and surface hardness.

- Rigorous Testing: Load capacity, fatigue resistance, and slip-resistance tests are routinely conducted to ensure safety and reliability.

- Custom Engineering: OEM partners benefit from tailored manufacturing processes that accommodate unique size, strength, and branding requirements.

Applications of Scaffolding Aluminum Planks

- Construction Sites: Used extensively for building construction, renovation, and maintenance, providing safe and stable working platforms.

- Industrial Plants: Facilitate equipment installation, inspection, and repair in factories and manufacturing facilities.

- Shipbuilding: Durable platforms for hull maintenance, painting, and repairs in marine environments.

- Event Staging: Temporary platforms for concerts, sports events, and exhibitions requiring quick assembly and disassembly.

- Rental Services: Many suppliers offer rental options with technical support, ideal for short-term or fluctuating project demands.

OEM Services and Customization

American manufacturers and suppliers are leaders in providing comprehensive OEM services for international brands, wholesalers, and producers:

- Private Labeling: Products can be branded with client logos and custom packaging to enhance market presence.

- Custom Sizing: Planks manufactured to precise dimensions and load ratings to meet project-specific needs.

- Technical Support: Engineering consultation, installation training, and after-sales service ensure optimal product use.

- Bulk Pricing: Competitive pricing models for large orders and long-term partnerships without compromising quality.

Logistics and Export Solutions

To facilitate global trade, American scaffolding aluminum plank suppliers offer:

- Durable Packaging: Use of reinforced crates, corrosion-resistant wraps, and waterproof materials to safeguard products during shipment.

- Efficient Shipping: Coordination with international freight forwarders to ensure timely delivery and smooth customs clearance.

- Comprehensive Documentation: Compliance with international trade regulations, including certificates of origin and safety compliance documents.

Innovations in Scaffolding Aluminum Planks

American manufacturers continuously innovate to enhance safety, efficiency, and environmental sustainability:

- Smart Safety Features: Anti-slip surfaces, integrated guard rails, and sensor technology to monitor plank stability and worker safety.

- Modular Designs: Quick-lock mechanisms and adjustable heights allow flexible configurations to suit diverse project requirements.

- Eco-Friendly Manufacturing: Use of recycled aluminum and energy-efficient production processes reduce environmental impact.

- Digital Asset Management: RFID tagging and digital tracking for inventory control and maintenance scheduling.

Conclusion

America's scaffolding aluminum planks manufacturers and suppliers are global leaders in quality, safety, and innovation. With a focus on advanced manufacturing, strict compliance, and comprehensive OEM services, these companies deliver lightweight, durable, and customizable solutions for construction and industrial clients worldwide. Whether you are a foreign brand, wholesaler, or producer seeking reliable OEM partners, American suppliers offer unmatched expertise, technical support, and global logistics to meet your needs.

FAQ

1. What are the main advantages of scaffolding aluminum planks over wood or steel?

Aluminum planks are lighter, easier to handle, and more resistant to corrosion. They require less maintenance and have a longer service life, making them cost-effective over time.

2. Do American manufacturers offer OEM and private label services?

Yes, most leading American scaffolding aluminum plank manufacturers provide comprehensive OEM services, including custom sizing, branding, and packaging.

3. Are American scaffolding aluminum planks compliant with global safety standards?

Yes, these products meet or exceed OSHA and ANSI standards and often comply with international regulations for export markets.

4. Can I order custom sizes or special features for my project?

Absolutely. Custom lengths, widths, load capacities, and safety features like anti-slip surfaces or guard rails can be specified.

5. How do American suppliers ensure product quality and safety?

Through automated manufacturing, rigorous testing protocols, and strict quality control measures, ensuring reliable and safe products.