Content Menu

● Overview of the German Scaffolding Market

● Why Choose Aluminum Planks for Scaffolding?

● Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in Germany

>> 1. Layher Holding GmbH & Co. KG

>> 2. Blizzard Gerüstsysteme

>> 3. WMH GROUP GERMANY

>> 4. MUNK Group

>> 5. Hünnebeck Deutschland GmbH

>> 6. Doka

>> 7. MEIN ROLLGERÜST

● Comparison: German vs. Chinese OEM Manufacturers

● Innovations and Trends in Scaffolding Aluminum Planks

>> Robotic Welding and Automated Production

>> Modular and Lightweight Systems

>> Enhanced Safety Features

>> Sustainability and Eco-Friendly Manufacturing

>> Smart Scaffolding Solutions

>> Digital Tools and Customer Support

● How to Select the Best Manufacturer or Supplier

>> Certifications and Compliance

>> Customization and OEM Services

>> Production Capacity and Delivery

>> After-Sales Support

>> Reputation and References

>> Pricing and Value

● Conclusion

● FAQ

>> 1. What are the main advantages of aluminum planks over steel or wood in scaffolding?

>> 2. Can German scaffolding manufacturers provide customized OEM solutions?

>> 3. How do Chinese OEM scaffolding aluminum planks compare to German products?

>> 4. What certifications should I look for when choosing a scaffolding aluminum plank supplier?

>> 5. Are there rental services available for scaffolding aluminum planks in Germany?

Germany stands at the forefront of construction innovation in Europe, renowned for its rigorous safety standards, advanced engineering, and a robust network of scaffolding aluminum planks manufacturers and suppliers. As the global demand for lightweight, durable, and efficient scaffolding solutions grows, German manufacturers are recognized for delivering products that meet the highest expectations of quality and reliability. This comprehensive guide explores the leading companies in Germany, compares their offerings with international OEM providers—especially from China—and provides insights into current trends, innovations, and best practices for sourcing scaffolding aluminum planks.

Overview of the German Scaffolding Market

Germany's construction industry is characterized by its adherence to strict safety regulations, cutting-edge technology, and a culture of continuous improvement. The country's central location in Europe makes it a strategic hub for both domestic projects and exports across the continent. Scaffolding aluminum planks have become a staple in German construction due to their superior strength-to-weight ratio, corrosion resistance, and compliance with DIN and EN standards.

German manufacturers are known for their precision engineering, offering a wide range of scaffolding solutions tailored to various applications—from residential renovations to large-scale infrastructure projects. Their focus on sustainability, automation, and customer service further cements Germany's reputation as a leader in the scaffolding industry.

The market's maturity has driven manufacturers to innovate continuously, integrating digital tools such as online configurators and virtual project planning to enhance customer experience. Moreover, the demand for eco-friendly construction materials has pushed companies to adopt sustainable manufacturing practices, including recycling aluminum scrap and reducing energy consumption in production.

Why Choose Aluminum Planks for Scaffolding?

Aluminum planks offer distinct advantages over traditional wood and steel alternatives:

- Lightweight: Aluminum planks weigh significantly less than steel, making transportation, handling, and assembly easier and safer. This reduces labor costs and project timelines.

- Corrosion Resistance: Unlike steel, aluminum does not rust, making it ideal for humid, coastal, or chemically aggressive environments.

- High Strength-to-Weight Ratio: Aluminum supports heavy loads while remaining light, ensuring safety without compromising ease of use.

- Long Service Life: Aluminum planks require minimal maintenance and resist environmental degradation, reducing replacement frequency and overall costs.

- Safety: Many aluminum planks come with anti-slip surfaces and are manufactured to comply with international safety standards, reducing accidents on-site.

- Sustainability: Aluminum is 100% recyclable, aligning with the growing demand for environmentally friendly construction materials.

These benefits make aluminum planks the preferred choice for modern construction, particularly in markets like Germany where efficiency, safety, and environmental responsibility are paramount.

Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in Germany

Germany is home to several leading scaffolding aluminum planks manufacturers and suppliers, each offering unique strengths and product portfolios.

1. Layher Holding GmbH & Co. KG

- Location: Güglingen-Eibensbach, Germany

- Products: Aluminum scaffolding planks, modular systems, rolling towers, and accessories

- Highlights: Layher is a global leader with over 80 years of experience, renowned for its precision-made scaffolding solutions. All products are manufactured in Germany, ensuring strict quality control and compliance with EN and DIN standards.

2. Blizzard Gerüstsysteme

- Location: Germany

- Products: Aluminum scaffolding planks, decks, frames, and complete scaffolding systems

- Highlights: Blizzard specializes in high-performance aluminum scaffolding with DIBt approval (Z-8.1-974), ensuring products meet German Institute for Building Technology standards. Their robust decks are widely used for façade and industrial scaffolding.

3. WMH GROUP GERMANY

- Location: Germany

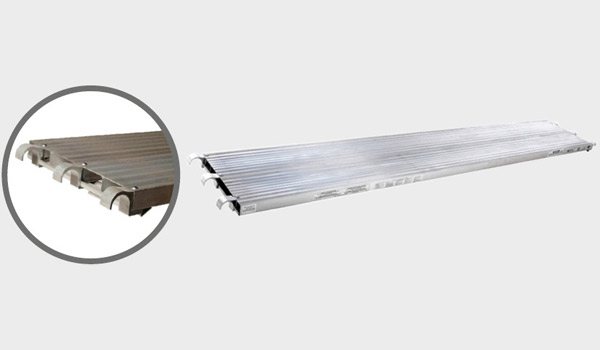

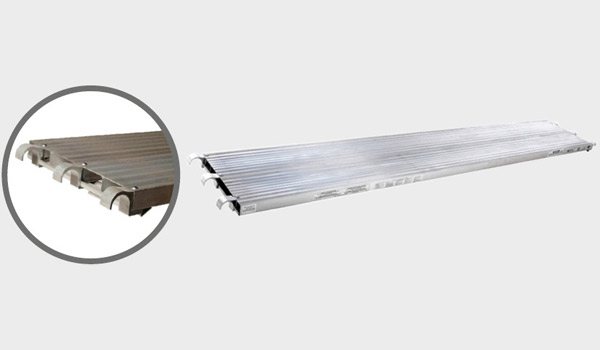

- Products: Design planks, grating planks, industrial planks, and custom aluminum solutions

- Highlights: WMH offers a diverse range of aluminum planks for industrial and construction applications, focusing on innovative designs and attachment solutions for various scaffolding systems.

4. MUNK Group

- Location: Günzburg, Germany

- Products: Certified aluminum scaffolding planks, ladders, and modular systems

- Highlights: MUNK Group is known for its certified manufacturing processes, offering a complete range of services from installation to maintenance. Their online configurators and training seminars support clients throughout the project lifecycle.

5. Hünnebeck Deutschland GmbH

- Location: Ratingen, Germany

- Products: Scaffolding boards, aluminum planks, formwork systems

- Highlights: Hünnebeck is a major supplier of scaffolding components, with a focus on innovative solutions and fast delivery across Germany and Europe.

6. Doka

- Location: Leverkusen, Germany

- Products: Aluminum scaffold planking, infill planks, stacking pallets

- Highlights: Doka is a global brand offering a wide range of scaffolding and formwork solutions, including lightweight aluminum planks designed for easy integration with various systems.

7. MEIN ROLLGERÜST

- Location: Leverkusen, Germany

- Products: Rolling scaffolds, aluminum planks, ladders, and accessories

- Highlights: Specializing in mobile scaffolding, MEIN ROLLGERÜST provides high-quality aluminum planks compatible with leading modular systems.

Comparison: German vs. Chinese OEM Manufacturers

Many international buyers compare German manufacturers with Chinese OEM suppliers when sourcing scaffolding aluminum planks. Here's how they compare:

| Feature | German Manufacturers | Chinese OEM Manufacturers |

| Quality Standards | EN, DIN, DIBt, TÜV | ISO, CE, EN, OSHA |

| Customization | High, project-specific | High, flexible MOQ, private labeling |

| Production Technology | Advanced automation, robotics | Advanced automation, robotic welding |

| Pricing | Higher (European labor costs) | Competitive, cost-effective |

| Delivery Time | Fast within Europe | 20-30 days after order confirmation |

| Export Markets | Europe, global | Global (Europe, America, Asia, Africa) |

| Certifications | DIBt, EN12810, EN12811, CE | ISO9001, EN1090, CE, OSHA |

Chinese OEM manufacturers, such as Bythai and Wellmade, offer factory-direct pricing, large-scale production, and a wide range of certifications. German manufacturers, however, provide superior local support, faster logistics within Europe, and products tailored to meet the strictest EU regulations.

Innovations and Trends in Scaffolding Aluminum Planks

Robotic Welding and Automated Production

German manufacturers leverage robotic welding and automated production lines to ensure consistent quality and high output. This technology minimizes human error and enhances the structural integrity of scaffolding aluminum planks.

Modular and Lightweight Systems

The trend toward modular scaffolding systems allows for rapid assembly and disassembly, reducing labor costs and increasing site safety. Lightweight aluminum planks are integral to these systems, enabling quick adaptation to changing project requirements.

Enhanced Safety Features

Anti-slip coatings, integrated guardrails, and locking mechanisms are now standard on many aluminum planks. These features are designed to prevent workplace accidents and comply with stringent safety regulations.

Sustainability and Eco-Friendly Manufacturing

German manufacturers are increasingly adopting sustainable practices, such as using recycled aluminum, energy-efficient production methods, and eco-friendly packaging. These initiatives support green building certifications and corporate social responsibility goals.

Smart Scaffolding Solutions

Emerging technologies include sensors embedded in aluminum planks to monitor load, stress, and environmental conditions in real time. These smart systems enhance safety by providing early warnings of potential hazards.

Digital Tools and Customer Support

Many German suppliers now offer online configurators and virtual planning tools, enabling customers to design scaffolding setups tailored to their projects. Combined with comprehensive training seminars and after-sales support, these digital tools improve project efficiency and safety.

How to Select the Best Manufacturer or Supplier

Choosing the right scaffolding aluminum planks manufacturer or supplier is crucial for project success. Consider the following factors:

Certifications and Compliance

Ensure the manufacturer complies with relevant standards such as EN12810, EN12811, DIN, DIBt, CE, ISO9001, and OSHA. These certifications guarantee product safety and quality.

Customization and OEM Services

Look for suppliers that offer OEM and customization options, including plank dimensions, surface finishes, and branding. This is particularly important for international brands, wholesalers, and project-specific requirements.

Production Capacity and Delivery

Assess the supplier's ability to meet your order volume and delivery timelines. Reliable manufacturers maintain sufficient stock or scalable production lines to avoid project delays.

After-Sales Support

Strong technical support, warranty policies, and responsive customer service are essential for resolving issues quickly and minimizing downtime.

Reputation and References

Research the supplier's reputation through client testimonials, case studies, and industry reviews. Established companies with a proven track record are more likely to deliver consistent quality.

Pricing and Value

While price is important, consider the total value—including durability, maintenance, and long-term performance—when selecting a supplier.

Conclusion

Germany is home to some of the world's most reputable scaffolding aluminum planks manufacturers and suppliers, known for their dedication to quality, safety, and innovation. Companies like Layher, Blizzard Gerüstsysteme, WMH Group, and MUNK Group set the benchmark for precision engineering and customer service. For international buyers, especially those seeking OEM solutions, Chinese manufacturers offer competitive alternatives with flexible customization and global certifications. Ultimately, the best choice depends on your project's requirements, budget, and desired level of support. By partnering with trusted suppliers, you can ensure the safety, efficiency, and success of your construction projects.

FAQ

1. What are the main advantages of aluminum planks over steel or wood in scaffolding?

Aluminum planks are lighter, corrosion-resistant, and have a higher strength-to-weight ratio, making them easier to handle and longer-lasting than steel or wood alternatives.

2. Can German scaffolding manufacturers provide customized OEM solutions?

Yes, most leading German manufacturers offer OEM services, allowing clients to customize plank sizes, surface treatments, and accessories to meet specific project needs.

3. How do Chinese OEM scaffolding aluminum planks compare to German products?

Chinese OEM manufacturers offer similar quality with competitive pricing, large-scale production, and international certifications. German products may offer faster delivery within Europe and a focus on local standards.

4. What certifications should I look for when choosing a scaffolding aluminum plank supplier?

Look for EN12810, EN12811, DIN, DIBt, CE, ISO9001, and OSHA certifications to ensure compliance with international safety and quality standards.

5. Are there rental services available for scaffolding aluminum planks in Germany?

Yes, many suppliers and distributors in Germany offer rental services for scaffolding aluminum planks, supporting both short-term and long-term construction projects.