Content Menu

● Overview of the Korean Scaffolding Aluminum Planks Market

● Why Choose Aluminum Planks for Scaffolding?

● Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in Korea

>> 1. Dong Myung Industrial Co., Ltd.

>> 2. Steel Korea Co., Ltd.

>> 3. Seobo Industrial Co., Ltd.

>> 4. Hory Korea Co., Ltd.

>> 5. KS Form

>> 6. Viser System

>> 7. EK Scaffolding

>> 8. Gainford

● Comparison: Korean vs. Chinese OEM Manufacturers

● Innovations and Trends in Scaffolding Aluminum Planks

>> Robotic Welding and Automated Production

>> Lightweight Modular Systems

>> Enhanced Safety Features

>> Sustainability Initiatives

>> Digital Tools and Customer Support

>> Logistics and Packaging Solutions

>> Rental and Service Expansion

● How to Select the Best Manufacturer or Supplier

● Conclusion

● FAQ

>> 1. What are the main advantages of aluminum planks over steel or wood in scaffolding?

>> 2. Can Korean scaffolding manufacturers provide customized OEM solutions?

>> 3. How do Chinese OEM scaffolding aluminum planks compare to Korean products?

>> 4. What certifications should I look for when choosing a scaffolding aluminum plank supplier?

>> 5. Are rental services available for scaffolding aluminum planks in Korea?

South Korea's construction industry is rapidly evolving, driven by urban development, infrastructure projects, and increasing safety regulations. Central to this growth is the demand for high-quality scaffolding aluminum planks, which are prized for their lightweight, durability, and safety features. Korean manufacturers and suppliers of scaffolding aluminum planks have built a strong reputation for precision engineering, compliance with international standards, and OEM capabilities that cater to global brand owners, wholesalers, and producers. This article delves into the top scaffolding aluminum planks manufacturers and suppliers in Korea, highlighting their products, innovations, and market trends, while also comparing Korean manufacturers with Chinese OEM providers. The article concludes with practical guidance for sourcing and selecting the best partners.

Overview of the Korean Scaffolding Aluminum Planks Market

South Korea's scaffolding market is characterized by rigorous quality control, advanced manufacturing technologies, and a focus on worker safety. Korean scaffolding aluminum planks are widely used in residential, commercial, and industrial construction projects, favored for their corrosion resistance, high strength-to-weight ratio, and ease of assembly. The market includes both local manufacturers with strong domestic presence and international suppliers offering OEM services.

Korean manufacturers emphasize compliance with ISO, CE, and Korean Industrial Standards, ensuring products meet stringent safety and performance criteria. The country's strategic location and efficient logistics infrastructure facilitate exports to Southeast Asia, the Middle East, and beyond. Many Korean companies also provide rental, installation, and technical support services, offering comprehensive solutions to their clients.

Moreover, the Korean construction industry is increasingly adopting digital technologies such as Building Information Modeling (BIM) and virtual reality (VR) to enhance scaffolding design and safety planning. This integration improves project efficiency and reduces risks associated with scaffold assembly and use.

Why Choose Aluminum Planks for Scaffolding?

Aluminum planks have become the preferred material for scaffolding platforms due to several advantages:

- Lightweight: Easier to transport and handle, reducing labor intensity and speeding up assembly and disassembly.

- Corrosion Resistance: Aluminum withstands harsh weather and chemical exposure, extending service life.

- High Strength-to-Weight Ratio: Supports heavy loads safely while remaining manageable.

- Durability: Minimal maintenance and long lifespan reduce replacement frequency.

- Safety: Anti-slip surfaces and compliance with international safety standards minimize accidents.

- Sustainability: Aluminum is fully recyclable, aligning with global environmental goals.

These benefits make aluminum planks indispensable in modern scaffolding systems, especially in markets like Korea where safety and efficiency are paramount.

Additionally, aluminum planks contribute to reducing the overall carbon footprint of construction projects. Their recyclability and the energy-efficient production methods adopted by many Korean manufacturers align with Korea's commitment to sustainable development. The lighter weight also means less fuel consumption during transportation, further enhancing environmental benefits.

Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in Korea

1. Dong Myung Industrial Co., Ltd.

- Location: Seoul, Korea

- Established: 1992

- Products: Steel pipe props, steel planks, scaffolding frames, scaffold couplers

- Highlights: Dong Myung is a leading Korean manufacturer known for durable, high-quality scaffolding products. Their aluminum planks are engineered for strength and ease of use. They offer OEM services to international clients and export extensively to Southeast Asia and the Middle East.

2. Steel Korea Co., Ltd.

- Location: Hwasung City, Gyeonggi-do

- Products: Scaffolding pipes, steel planks, mobile scaffold towers

- Highlights: Steel Korea has a strong export presence and offers ISO-certified products. Their galvanized steel and aluminum planks are widely used domestically and abroad. The company provides OEM services and detailed product information online.

3. Seobo Industrial Co., Ltd.

- Location: Chungcheongbuk-do

- Products: Aluminum formwork, scaffold accessories, bridge systems

- Highlights: Specializes in scaffold accessories and aluminum planks with ISO 9001 and ISO 14001 certifications. Seobo offers OEM services and has expanded internationally with branches in Seoul and New Delhi.

4. Hory Korea Co., Ltd.

- Location: Gimhae-si, Gyeongsangnam-Do

- Established: 2000

- Products: Steel pipes, ringlock scaffolding, euro forms, scaffolding ledgers

- Highlights: Hory Korea exports extensively to East and Southeast Asia, including Japan and Russia. Their aluminum planks are competitively priced and meet international standards.

5. KS Form

- Location: Seoul, Gangnam-gu

- Products: Scaffold standards, jack bases, ringlock ledgers

- Highlights: KS Form is committed to 100% domestic manufacturing (except timber beams). Their products reduce shipping costs and are tailored to local construction needs. OEM and customization services are available.

6. Viser System

- Location: Gimhae-si

- Established: 2004

- Products: Ringlock scaffolding, jack bases, scaffold pipes

- Highlights: Viser System partners with Japanese manufacturers and Samsung Heavy Industries. They focus on innovation, quality assurance, and OEM partnerships.

7. EK Scaffolding

- Location: Korea

- Products: Walk-thru frames, mason frames, ladder frames, H frames

- Highlights: EK Scaffolding's walk-thru frames feature ergonomic, lightweight designs for fast assembly. OEM services are offered for international clients.

8. Gainford

- Location: Korea

- Products: Galvanized frame scaffolding, walk-thru frames

- Highlights: Known for high compressive strength and environmentally friendly galvanizing, Gainford's aluminum planks serve residential, commercial, and industrial projects.

Comparison: Korean vs. Chinese OEM Manufacturers

| Feature | Korean Manufacturers | Chinese OEM Manufacturers |

| Quality Standards | ISO, CE, Korean Industrial Standards | ISO, CE, EN, OSHA |

| Customization | High, project-specific | High, flexible MOQ, private labeling |

| Production Technology | Robotic welding, automated lines | Advanced automation, robotic welding |

| Pricing | Higher (due to labor and quality) | Competitive, cost-effective |

| Delivery Time | Fast within Asia | 20-30 days post order confirmation |

| Export Markets | Asia, Middle East, global | Global (Europe, America, Asia, Africa) |

| Certifications | ISO9001, CE | ISO9001, EN1090, CE, OSHA |

Korean manufacturers emphasize quality, local support, and compliance with safety standards. Chinese OEM suppliers offer cost advantages and flexible OEM services, making them attractive for brands and wholesalers expanding product lines.

Innovations and Trends in Scaffolding Aluminum Planks

Robotic Welding and Automated Production

Korean manufacturers use robotic welding and CNC machining to produce high-strength, uniform aluminum planks, reducing defects and enhancing safety.

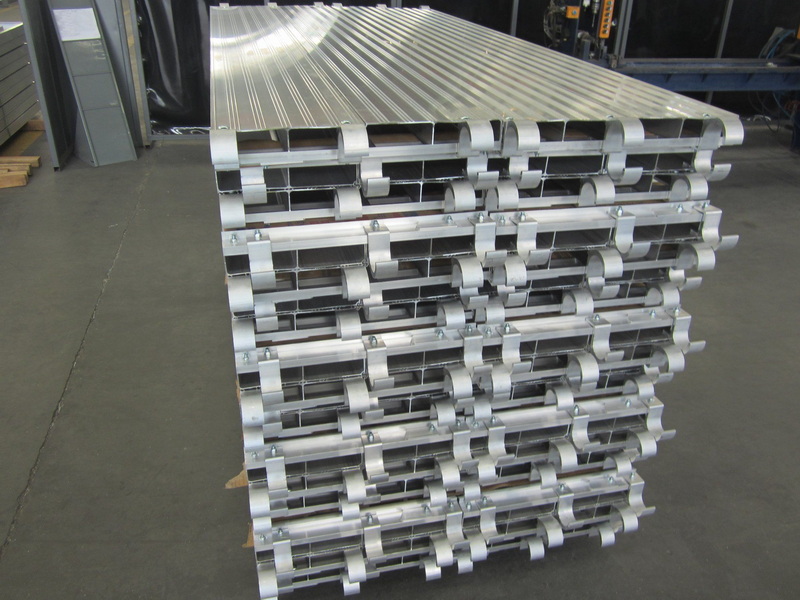

Lightweight Modular Systems

Modular scaffolding with lightweight aluminum planks enables rapid assembly and disassembly, reducing labor costs and improving site safety.

Enhanced Safety Features

Anti-slip coatings, integrated guardrails, and locking mechanisms comply with Korea's strict workplace safety regulations.

Sustainability Initiatives

Recycling aluminum and energy-efficient manufacturing processes align with Korea's environmental policies and green building certifications.

Digital Tools and Customer Support

Online configurators, virtual scaffolding design tools, and after-sales support improve customer experience and project efficiency.

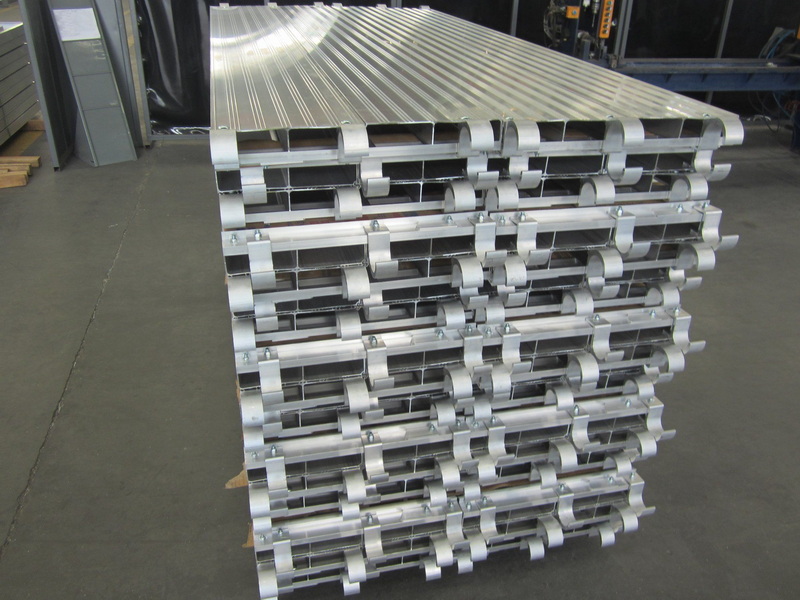

Logistics and Packaging Solutions

Korean suppliers use steel pallets, crates, and protective coatings to ensure product integrity during shipping. OEM clients benefit from customized packaging and branding options.

Rental and Service Expansion

Many Korean manufacturers have expanded their offerings to include scaffolding rental, installation, and maintenance services. This full-service approach helps clients reduce upfront investment and ensures scaffolding systems are managed safely and efficiently throughout project lifecycles.

How to Select the Best Manufacturer or Supplier

- Certifications and Compliance: Verify ISO, CE, Korean Industrial Standards.

- Customization and OEM Services: Look for flexible OEM options including branding and packaging.

- Production Capacity and Delivery: Ensure timely order fulfillment.

- After-Sales Support: Consider warranty, technical assistance, and training.

- Reputation and References: Check testimonials and industry reputation.

- Pricing and Value: Balance cost with durability and service quality.

Conclusion

South Korea boasts a strong network of reputable scaffolding aluminum planks manufacturers and suppliers such as Dong Myung Industrial, Steel Korea, and Seobo Industrial. Their products combine quality, safety, and innovation, serving domestic and international markets. Chinese OEM manufacturers provide competitive pricing and customization options, complementing the Korean market. Selecting the right supplier depends on your project needs, budget, and service expectations. Partnering with trusted Korean manufacturers ensures reliable, safe, and efficient scaffolding solutions for successful construction projects worldwide.

FAQ

1. What are the main advantages of aluminum planks over steel or wood in scaffolding?

Aluminum planks are lighter, corrosion-resistant, and have a higher strength-to-weight ratio, making them easier to handle and longer-lasting than steel or wood.

2. Can Korean scaffolding manufacturers provide customized OEM solutions?

Yes, many Korean manufacturers offer OEM services, including size customization, surface treatments, branding, and packaging.

3. How do Chinese OEM scaffolding aluminum planks compare to Korean products?

Chinese OEM manufacturers offer competitive pricing and flexible customization, while Korean products emphasize superior quality and local support.

4. What certifications should I look for when choosing a scaffolding aluminum plank supplier?

Look for ISO, CE, and Korean Industrial Standards certifications to ensure compliance with safety and quality standards.

5. Are rental services available for scaffolding aluminum planks in Korea?

Yes, many Korean suppliers offer rental and installation services for scaffolding aluminum planks.