Content Menu

● What Are Scaffolding Couplers?

● Importance of Quality in Scaffolding Coupler Manufacturing

● Top Scaffolding Coupler Manufacturers and Suppliers in Australia

>> 1. Aussie Scaffolding Components

>> 2. SteelLink Couplers Pty Ltd

>> 3. IronGrid Engineering

>> 4. TrueBuild Supplies

>> 5. NextGen Scaffold Solutions

● Manufacturing Process of Scaffolding Couplers in Australia

● Industry Standards and Certifications

● Applications of Scaffolding Couplers

● Export and OEM Services

● Conclusion

● FAQ

>> 1. What materials are commonly used by Australian scaffolding coupler manufacturers?

>> 2. How do Australian manufacturers ensure the reliability of their scaffolding couplers?

>> 3. Do Australian scaffolding coupler manufacturers provide OEM services?

>> 4. What surface treatments protect scaffolding couplers from corrosion in Australia?

>> 5. Are Australian scaffolding couplers suitable for export to global markets?

Scaffolding is the backbone of safe and efficient construction projects, and scaffolding couplers play a crucial role in ensuring the strength and reliability of these temporary structures. Australia has established itself as home to some of the leading scaffolding coupler manufacturers and suppliers, offering high-quality products that meet stringent local and international standards.This article offers an in-depth overview of the top scaffolding coupler manufacturers and suppliers in Australia, their manufacturing processes, product types, industry certifications, and their abilities to provide OEM services to international clients such as brand owners, wholesalers, and producers. By understanding the Australian market's strengths and key players, businesses can make informed decisions when sourcing scaffolding couplers for diverse construction applications.

What Are Scaffolding Couplers?

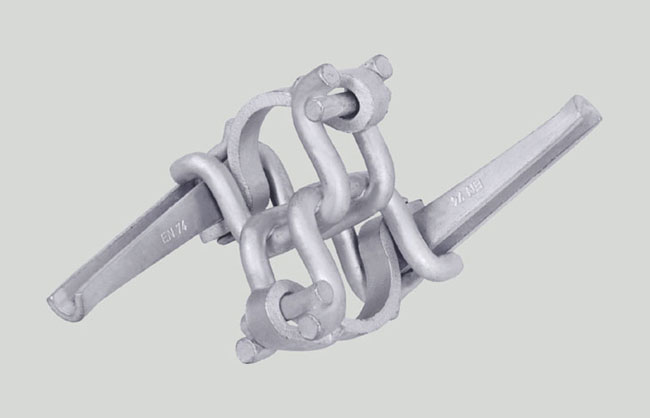

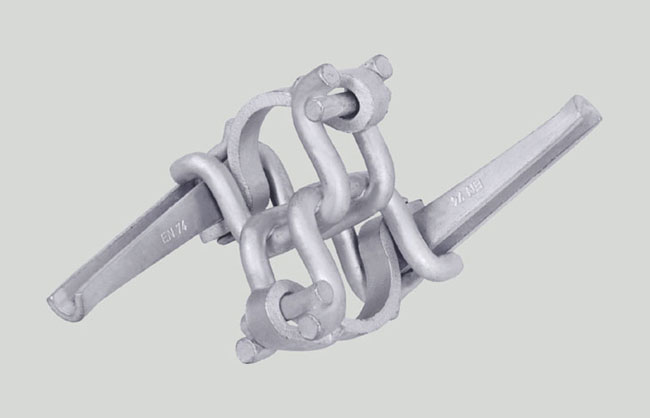

Scaffolding couplers are mechanical devices designed to join scaffolding tubes securely and safely. They are the essential connectors that maintain the structural integrity of scaffolding systems, allowing them to bear loads while ensuring workers' safety.

There are mainly three types of scaffolding couplers popular in Australia:

- Right-angle couplers: Join two tubes at 90 degrees, commonly used to connect ledgers and standards.

- Swivel couplers: Allow tubes to join at any angle, providing flexibility when erecting complex scaffolding.

- Sleeve couplers: Join two tubes end to end to extend the scaffold length.

Each type is engineered and manufactured to withstand significant mechanical loads and environmental conditions typical of construction sites across Australia.

Pressed couplers and forged couplers are two important manufacturing types. Pressed couplers are created by stamping steel sheets and welding; forged couplers are produced by forging solid steel billets at high temperatures, resulting in higher strength. Australian manufacturers are experienced in producing both types to cater to different load requirements and project specifications.

Importance of Quality in Scaffolding Coupler Manufacturing

The quality of scaffolding couplers directly affects the safety and durability of scaffolding systems. Inferior couplers can lead to structural failures, posing risks to workers and causing costly project delays.

Leading Australian manufacturers invest heavily in:

- Premium raw materials: Typically high-tensile steel or alloy steel, ensuring durability and strength.

- Advanced manufacturing technology: Sophisticated forging, pressing, and machining equipment to maintain tight tolerances.

- Surface treatments: Hot-dip galvanization or powder coating to prevent corrosion, prolonging product lifespan.

- Rigorous quality control: Testing welded joints, dimensional accuracy, load-bearing capacity, and corrosion resistance in line with Australian standards.

Emerging technology in manufacturing, such as robotic welding and 3D scanning for dimensional control, has improved the consistency and safety of couplers. Manufacturers are also innovating to reduce the environmental impact by adopting greener energy sources and recycling steel waste.

Top Scaffolding Coupler Manufacturers and Suppliers in Australia

1. Aussie Scaffolding Components

Aussie Scaffolding Components is a leading Australian manufacturer specializing in high-grade scaffolding couplers with a comprehensive product range, including right-angle, swivel, and sleeve couplers.

Key Features:

- Uses premium steel sourced locally and overseas.

- Advanced forging and CNC machining capabilities.

- Fully compliant with Australian and international standards including AS/NZS 1576.

- Offers flexible OEM services for international brand owners.

- Environmentally friendly galvanizing process.

This company's investment in research and development makes it a pioneer in introducing lightweight couplers with comparable strength to traditional models, significantly reducing the labor strain during assembly.

2. SteelLink Couplers Pty Ltd

SteelLink Couplers has a reputation as one of Australia's reliable suppliers and manufacturers of scaffolding components. They focus on precision-manufactured couplers suitable for commercial and industrial construction.

Key Features:

- Wide spectrum of coupler designs with custom engineering options.

- ISO 9001 certified production facilities.

- Fast turnaround for OEM bulk orders with branded packaging.

- Strong export presence to Asia-Pacific markets.

SteelLink is known for partnering closely with customers for tailor-made couplers designed for specific safety or load-bearing requirements, which is essential in highly regulated industrial environments.

3. IronGrid Engineering

IronGrid Engineering combines traditional forging methods with modern automated finishing processes to produce durable, top-quality scaffolding couplers. Their focus is on strength, safety, and innovation.

Key Features:

- Certified to meet Australian standards AS/NZS 1576 and ISO 9001.

- Offers tailored OEM manufacturing solutions.

- Comprehensive in-house testing including tensile and fatigue tests.

- Proven track record supplying large construction projects nationally.

IronGrid has recently developed a new corrosion-resistant alloy coupler, aimed at mining and coastal constructions, where harsh environmental conditions usually accelerate rust and degradation.

4. TrueBuild Supplies

With a customer-centric approach, TrueBuild Supplies acts both as a manufacturer and a distributor of scaffolding couplers in Australia. Their product line balances quality with affordability to serve a broad market from residential builders to large contractors.

Key Features:

- Extensive stock of right-angle and swivel couplers.

- OEM packaging options with private labeling.

- Compliance with Australian safety regulations.

- Dedicated technical support for installation best practices.

TrueBuild is also noted for its customer education programs, providing on-site training and webinars, which helps clients improve on-site safety and reduces the risk of scaffolding failure linked to improper coupler use.

5. NextGen Scaffold Solutions

NextGen Scaffold Solutions prides itself on innovation and sustainable manufacturing. They produce scaffolding couplers with advanced corrosion-resistant coatings and offer custom design services for clients with specific project needs.

Key Features:

- Use of eco-friendly galvanizing techniques.

- Custom OEM services including bespoke packaging.

- Active R&D to improve coupler strength-to-weight ratio.

- Strong presence in export markets including the Middle East and Southeast Asia.

NextGen's sustainability initiatives include using recycled steel and minimizing VOC emissions during surface treatment processes, making them a leader in green manufacturing in the scaffolding coupler industry.

Manufacturing Process of Scaffolding Couplers in Australia

Australian scaffolding coupler manufacturers typically follow these detailed procedures to ensure superior quality and consistency:

1. Raw Material Selection

High-grade carbon or alloy steel is sourced from trusted suppliers, ensuring materials meet Australian standards for strength and toughness.

2. Forging or Pressing

Depending on coupler type, parts may be forged — shaping hot steel billets under high pressure — or pressed and welded from steel sheets for lighter couplers.

3. Precision Machining and Finishing

CNC machining fine-tunes dimensions and creates bolt holes, while deburring and polishing improve safety by eliminating sharp edges.

4. Advanced Surface Treatment

Hot-dip galvanization remains the gold standard for corrosion protection. Powder coating supplements it in some cases, especially when color coding or branding is required.

5. Stringent Quality Control and Testing

Each batch undergoes dimensional checks with laser measurement tools, weld inspections via X-ray or ultrasonic scans, tensile and fatigue testing in certified laboratories, and corrosion resistance verification through salt spray chambers.

6. Packaging and OEM Customization

Finished products are packaged with protective materials tailored to client specifications. Many manufacturers offer customized labeling, pack sizes, and brochures as part of their OEM service.

Industry Standards and Certifications

Australian scaffolding coupler manufacturers rigorously comply with:

- AS/NZS 1576: The benchmark Australian/New Zealand standard covering scaffolding components.

- ISO 9001: A globally recognized quality management system standard certifying manufacturing processes.

- AS/NZS 4725: Specific requirements covering metallic scaffolding components including couplers.

- UKCA and CE Marking: For products exported to the United Kingdom and European Union, confirming compliance with their safety directives.

Strict adherence to these certifications ensures products are fit for purpose not only within Australia but on global construction sites, meeting diverse regulatory requirements.

Applications of Scaffolding Couplers

Manufactured and supplied scaffolding couplers in Australia are used in a wide variety of sectors:

- Commercial Construction: Skyscrapers, office blocks, and other large projects where scaffolding systems must support heavy loads and adverse weather conditions.

- Residential Building: Smaller scaffolding used in housing developments and renovation work.

- Industrial Facilities: Power plants, mining sites, and factories where specialized couplers are needed for unique operational stresses.

- Maintenance and Repair: Temporary access scaffolding for painting, cleaning, or repairs on existing infrastructure.

- Events and Temporary Structures: Concerts, exhibitions, and public events requiring quick assembly/disassembly scaffolding solutions.

Export and OEM Services

Many Australian scaffolding coupler manufacturers have a broad offering of OEM services for international clients, including:

- Tailored product designs to meet exact client specifications and project needs.

- Private labeling, customized packaging, and promotional materials.

- Strict quality control per client contracts.

- Logistics and export documentation handling to facilitate smooth international shipping.

- Scalable production from small prototype batches to large-volume contracts.

Australia's reputation for consistency, quality, and compliance has led to increased demand for scaffolding couplers in key export regions including Asia-Pacific, the Middle East, Africa, and Europe.

Conclusion

Australia's scaffolding coupler manufacturers and suppliers stand at the forefront of safety, quality, and innovation in the global construction industry. Their commitment to using premium materials, advanced manufacturing technology, and robust quality assurance ensures scaffolding couplers that perform reliably in diverse conditions.

For international brand owners, wholesalers, and producers looking for dependable OEM partners, Australian manufacturers offer not only durable, compliant products but also tailored services designed to meet the demands of competitive global markets. Partnering with Australia's top scaffolding coupler manufacturers guarantees access to world-class products that contribute to safer and more efficient construction operations worldwide.

FAQ

1. What materials are commonly used by Australian scaffolding coupler manufacturers?

High-strength carbon steel and alloy steel with excellent mechanical properties and weldability are the main materials used to ensure durability and safety.

2. How do Australian manufacturers ensure the reliability of their scaffolding couplers?

By adhering to standards such as AS/NZS 1576 and ISO 9001 and conducting rigorous tests including load, fatigue, weld integrity, and corrosion resistance.

3. Do Australian scaffolding coupler manufacturers provide OEM services?

Yes, comprehensive OEM services including product customization, private labeling, packaging, and custom documentation are offered.

4. What surface treatments protect scaffolding couplers from corrosion in Australia?

Hot-dip galvanization is standard, often supplemented with powder coating for enhanced protection and customization.

5. Are Australian scaffolding couplers suitable for export to global markets?

Absolutely. With certifications such as AS/NZS standards and CE/UKCA markings for exports, Australian couplers meet international safety and compliance requirements.