Content Menu

● What Are Scaffolding Couplers?

● Leading Scaffolding Coupler Manufacturers and Suppliers in Russia

>> Polatl and the “Soyuz” Ringlock System

>> LLC TRUST ROSSEM and JSC AMARANT

● Chinese OEM Manufacturers Supporting the Russian Market

● Types of Scaffolding Couplers Commonly Used in Russia

>> 1. Drop Forged Double Coupler

>> 2. Swivel Coupler

>> 3. Sleeve Coupler

>> 4. Putlog Coupler

>> 5. Beam Coupler

● Materials and Surface Treatments

● Quality Standards and Certifications

● Innovations and Market Trends in Russia

● Choosing the Right Scaffolding Coupler Supplier in Russia

● Conclusion

● FAQ

>> 1. What types of scaffolding couplers are most commonly used in Russia?

>> 2. Are Russian scaffolding coupler manufacturers compliant with safety standards?

>> 3. Can scaffolding couplers be customized for specific projects?

>> 4. What materials and surface treatments are used for scaffolding couplers in Russia?

>> 5. How do Chinese OEM manufacturers support the Russian scaffolding market?

In the construction and industrial sectors, scaffolding couplers are critical components that ensure the safety, stability, and flexibility of scaffolding systems. Russia, with its vast infrastructure projects and growing construction market, demands high-quality scaffolding couplers from reliable manufacturers and suppliers. This article explores the top scaffolding coupler manufacturers and suppliers in Russia, their product offerings, certifications, innovations, and the role of international OEM partnerships, especially with Chinese manufacturers. The content integrates key terms such as Scaffolding Coupler, Manufacturers, Suppliers while maintaining a fluent and professional tone.

What Are Scaffolding Couplers?

Scaffolding couplers are mechanical fittings used to securely connect scaffolding tubes and components. They provide the structural integrity and safety necessary for scaffolding systems to support workers and materials at heights. The main types of couplers include:

- Drop Forged Double Couplers (fixed right-angle clamps)

- Swivel Couplers (allowing angular flexibility)

- Sleeve Couplers (joining tubes end-to-end)

- Putlog Couplers (connecting tubes to ledgers or transoms)

- Beam Couplers (attaching tubes to beams or structural elements)

Manufactured primarily from forged or pressed steel, scaffolding couplers often feature galvanization or other surface treatments to resist corrosion and extend service life. Russian standards align closely with European norms, requiring couplers to meet strict safety and quality benchmarks.

Leading Scaffolding Coupler Manufacturers and Suppliers in Russia

Russia hosts several prominent scaffolding coupler manufacturers and suppliers known for their robust products and extensive market reach.

| Manufacturer/Supplier | Location | Product Highlights | Certifications & Notes |

| Polatl | Moscow | Ringlock system “Soyuz”, drop forged couplers, scaffolding systems | Over 10 years experience, built Europe’s highest scaffolding (440m) |

| LLC TRUST ROSSEM | Russia | Wide range of scaffolding parts including couplers | Leading exporter, 57% market share in scaffolding parts exports |

| JSC AMARANT | Russia | Scaffolding couplers, cross braces, formwork parts | 30% market share in exports, ISO and safety compliant |

| JSC PROMSTROYKONTRAKT | Russia | Scaffolding and construction formwork components | 5% export share, quality certifications |

| TD PIONER | Moscow Region | Scaffolding dismantling, steel transformation, couplers | Professional scaffolding supplier with broad services |

Polatl and the “Soyuz” Ringlock System

Polatl is a leading Russian scaffolding manufacturer and supplier, renowned for its unique Ringlock system “Soyuz”. This system is widely used across Russia for its safety, ease of assembly, and adaptability to high-altitude projects. Polatl's scaffolding has been deployed in over 10,000 construction sites nationwide, including Europe's highest scaffolding at over 440 meters. Their couplers and fittings are engineered for durability in Russia's harsh climates and comply with international safety standards.

LLC TRUST ROSSEM and JSC AMARANT

LLC TRUST ROSSEM dominates the Russian scaffolding parts export market, accounting for over half of the shipments globally. Their product range includes high-quality scaffolding couplers designed for various construction needs. JSC AMARANT follows closely, providing a broad portfolio of scaffolding components with strict adherence to quality and safety standards, making them trusted suppliers both domestically and internationally.

Chinese OEM Manufacturers Supporting the Russian Market

Chinese OEM manufacturers play a significant role in the Russian scaffolding coupler market by offering cost-effective, high-quality products that meet Russian and international standards. Wellmade Group, for example, is a certified manufacturer supplying galvanized scaffolding couplers compatible with Russian systems.

Key benefits of Chinese OEM partnerships include:

- Competitive Pricing: Lower production costs without compromising quality.

- Customization: Tailored couplers with specific dimensions, coatings, and branding.

- Certifications: Compliance with ISO9001, CE, and other relevant standards.

- High Production Capacity: Ability to fulfill large orders with consistent quality.

- Technological Advancements: Automated manufacturing and quality control.

These partnerships enable Russian suppliers and wholesalers to diversify their offerings and maintain competitive pricing while ensuring product reliability.

Types of Scaffolding Couplers Commonly Used in Russia

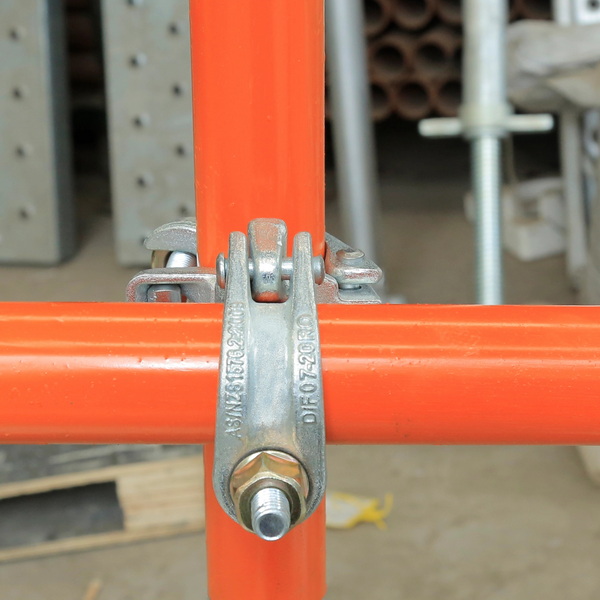

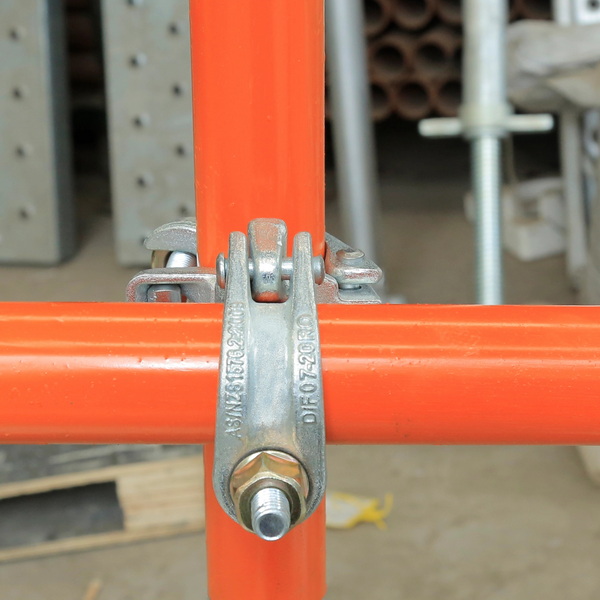

1. Drop Forged Double Coupler

This is the most common coupler type, connecting two tubes at a fixed 90-degree angle. Russian manufacturers produce these couplers with hot-dip galvanization for corrosion resistance, suitable for harsh weather conditions.

2. Swivel Coupler

Swivel couplers allow tubes to be connected at any angle, providing flexibility for complex scaffolding geometries. They are essential for adapting scaffolding to irregular structures.

3. Sleeve Coupler

Used to join two tubes end-to-end, sleeve couplers enable scaffold extensions or repairs without dismantling the entire system.

4. Putlog Coupler

Putlog couplers connect scaffold tubes to ledgers or transoms, supporting working platforms and ensuring stability.

5. Beam Coupler

Beam couplers attach scaffolding tubes to steel beams or other structural elements, integrating scaffolding with permanent structures.

Materials and Surface Treatments

Russian scaffolding couplers are primarily made from high-strength forged steel or pressed steel, treated with:

- Hot-Dip Galvanizing: Provides thick, durable corrosion protection.

- Electro-Galvanizing: Offers a thinner zinc coating for less aggressive environments.

- Powder Coating: Some couplers feature colored coatings for branding or additional protection.

These treatments ensure couplers withstand Russia's diverse climates and maintain long service lives.

Quality Standards and Certifications

Russian scaffolding coupler manufacturers and suppliers adhere to strict quality and safety standards, including:

- GOST Standards: Russian national standards for construction materials.

- ISO 9001: International quality management certification.

- CE Marking: Confirms compliance with European safety directives.

- EN 74: European standard for scaffolding couplers and fittings (often referenced).

- BS 1139: British standard frequently applied in Russian projects.

Compliance guarantees that couplers meet mechanical strength, durability, and safety requirements necessary for construction in Russia.

Innovations and Market Trends in Russia

The Russian scaffolding market is evolving with several notable trends:

- Modular Systems: Increased use of ringlock and frame scaffolding systems for faster assembly.

- Sustainability: Adoption of eco-friendly galvanizing and recycling practices.

- Digitalization: Use of BIM (Building Information Modeling) and 3D modeling for scaffold design and safety planning.

- Smart Scaffolding: Integration of sensors to monitor load and structural integrity in real time.

- Ergonomic Designs: Improved coupler designs to reduce installation time and enhance worker safety.

- Training Programs: Enhanced safety and installation training provided by manufacturers and suppliers.

These trends reflect Russia's commitment to modernizing construction safety and efficiency.

Choosing the Right Scaffolding Coupler Supplier in Russia

When selecting a scaffolding coupler supplier, consider:

- Certification and Compliance: Verify adherence to GOST, ISO, CE, and other standards.

- Product Range: Availability of various coupler types for different scaffolding needs.

- Customization and OEM Services: Ability to provide tailored solutions and branding.

- Quality Assurance: Robust quality control and testing processes.

- Customer Support: Technical assistance, training, and after-sales service.

- Delivery and Logistics: Reliable supply chain and timely delivery.

- Reputation: Established track record and positive customer feedback.

Russian manufacturers and suppliers, often collaborating with Chinese OEMs, offer comprehensive solutions that meet these criteria.

Conclusion

Russia's scaffolding industry is supported by a strong network of scaffolding coupler manufacturers and suppliers delivering certified, high-quality, and innovative products. Leading companies such as Polatl with its “Soyuz” Ringlock system, LLC TRUST ROSSEM, JSC AMARANT, and JSC PROMSTROYKONTRAKT dominate the market with reliable scaffolding couplers designed for Russia's demanding environments. Complementing these are Chinese OEM manufacturers, who provide cost-effective, customizable scaffolding couplers that meet Russian and international standards. Together, these manufacturers and suppliers ensure that Russian contractors, wholesalers, and brand owners have access to safe, compliant, and efficient scaffolding solutions. Selecting the right couplers and trusted partners is key to project success and worker safety.

FAQ

1. What types of scaffolding couplers are most commonly used in Russia?

The most common types include drop forged double couplers, swivel couplers, sleeve couplers, putlog couplers, and beam couplers, each serving specific structural functions.

2. Are Russian scaffolding coupler manufacturers compliant with safety standards?

Yes, leading manufacturers comply with GOST, ISO 9001, CE marking, and often reference EN 74 and BS 1139 standards to ensure product safety and quality.

3. Can scaffolding couplers be customized for specific projects?

Yes, many manufacturers and OEM suppliers offer customization in size, finish, branding, and packaging to meet unique project or client requirements.

4. What materials and surface treatments are used for scaffolding couplers in Russia?

Couplers are primarily made from forged or pressed steel with hot-dip galvanizing or electro-galvanizing finishes to withstand harsh climates.

5. How do Chinese OEM manufacturers support the Russian scaffolding market?

Chinese OEM manufacturers provide high-quality, certified scaffolding couplers at competitive prices, offering customization and helping Russian brands expand product offerings efficiently.