Content Menu

● What Are Scaffolding Tubes?

● Importance of Scaffolding Tubes in Canadian Construction

● Manufacturing Process of Scaffolding Tubes in Canada

● Leading Scaffolding Tube Manufacturers and Suppliers in Canada

>> Scaffold Depot

>> Layher North America

>> Canada Scaffold Supply

>> Safetech Scaffold Ltd.

>> Urban Scaffolding Ltd.

● Types of Scaffolding Tubes

● Applications of Scaffolding Tubes

● Conclusion

● FAQ

>> 1. What are the standards for scaffolding tubes in Canada?

>> 2. What materials are scaffolding tubes commonly made from?

>> 3. How is corrosion prevented in scaffolding tubes?

>> 4. Can scaffolding tubes be custom manufactured?

>> 5. What are the advantages of aluminum scaffolding tubes?

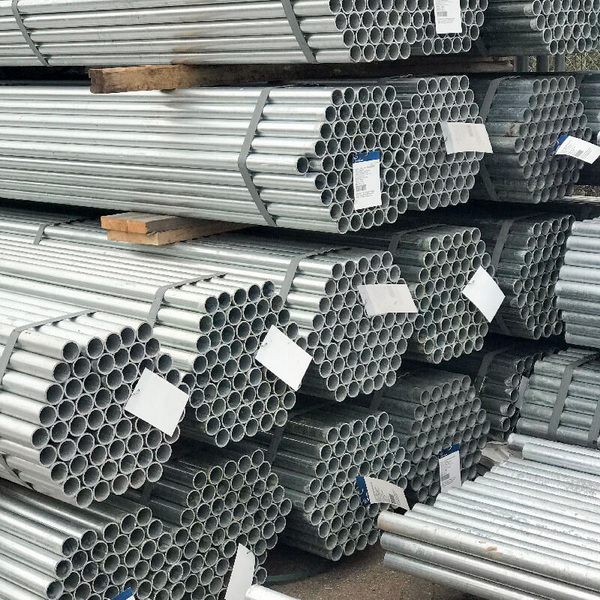

Scaffolding tubes are fundamental structural elements in the scaffolding systems used extensively across Canada's construction, industrial, and infrastructure sectors. These tubes provide the essential support framework that guarantees safety, stability, and performance for workers and materials at height. Given the rigorous safety regulations and diverse climate conditions across Canada, high-quality scaffolding tubes that comply with standards and offer durability are a necessity.This article presents an in-depth look at the top scaffolding tube manufacturers and suppliers in Canada.

What Are Scaffolding Tubes?

Scaffolding tubes are tubular steel or aluminum pipes used to build scaffolding frameworks. They provide the structure necessary to support platforms, workers, and equipment during construction, maintenance, or industrial operations. These tubes are engineered to high strength standards, providing resistance to heavy loads, impact, and environmental wear. Variations exist in material, diameter, wall thickness, and surface treatment based on application needs.

Importance of Scaffolding Tubes in Canadian Construction

Canadian construction industry demands scaffolding tubes that:

- Meet strict Canadian standards such as CSA G40.21 and ASTM A53, specifying tensile strength, mechanical properties, and chemical composition.

- Withstand severe weather elements including snow, rain, temperature fluctuations, and coastal salt corrosion.

- Offer secure fitting compatibility with standard scaffolding connectors and couplers.

- Facilitate quick assembly and disassembly to optimize labor use.

- Provide versatile options across residential, commercial, industrial, and infrastructure projects.

Manufacturing Process of Scaffolding Tubes in Canada

Canadian scaffolding tube manufacturing is a combination of traditional metallurgy and modern automated fabrication techniques:

1. Raw Material Sourcing

Steel coils or billets meeting Canadian steel specifications are procured. These could be carbon steel, galvanized steel, or aluminum.

2. Forming and Shaping

Flat steel strips undergo roll forming into tubular profiles. For seamless tubes, solid billets pass through rotary piercers and mandrels.

3. Welding

High-frequency welding seals longitudinal seams in welded tubes. Seamless tubes bypass this as they are extruded fully closed.

4. Heat Treatment

Tubes may be heat treated to improve strength and relieve manufacturing stresses.

5. Surface Treatment

Tubes are hot-dip galvanized or powder coated to boost corrosion resistance, especially vital for Canadian climates.

6. Cutting and Finishing

Tubes are precision cut to specified lengths, chamfered or beveled as required, and inspected for dimensional consistency.

7. Quality Control

Non-destructive testing methods including ultrasonic and eddy current inspections detect defects. Mechanical tests verify tensile strength and durability against standards.

8. Packaging and Distribution

Tubes are bundled and labeled per buyer specifications, ready for prompt delivery across Canada and export.

Leading Scaffolding Tube Manufacturers and Suppliers in Canada

Scaffold Depot

Based in Surrey, British Columbia, Scaffold Depot operates a state-of-the-art automated manufacturing facility capable of producing galvanized steel and aluminum scaffolding tubes. Their tubes comply fully with CSA and ASTM standards, and they are well-known for fast turnaround and customization services.

Layher North America

Layher NA supplies premium steel and aluminum scaffolding tubes teamed with advanced modular system technology. Their products meet Canadian structural requirements and have earned a reputation in industrial and commercial projects nationwide.

Canada Scaffold Supply

Canada Scaffold Supply specializes in high-strength galvanized steel tubes tailored to Canadian construction needs. Their extensive stock and distribution network ensures consistent supply for small to large scale projects.

Safetech Scaffold Ltd.

Safetech delivers durable scaffolding tubes optimized for the Canadian safety context, offering maintenance, rentals, and custom-built scaffold systems supported by quality tube components.

Urban Scaffolding Ltd.

Serving Edmonton and beyond, Urban Scaffolding provides lightweight aluminum tubes and galvanized steel tubes engineered for robustness and ease of handling, catering to Alberta's construction markets.

Types of Scaffolding Tubes

- Steel Tubes: Carbon steel, generally hot-dip galvanized for longevity.

- Aluminum Tubes: Lightweight and corrosion-resistant, ideal for rapid mobilization.

- Stainless Steel Tubes: High corrosion resistance, used in chemical or coastal environments.

- Galvanized Tubes: Zinc-coated tubes for additional environmental protection.

Applications of Scaffolding Tubes

- Construction scaffolds for residential, commercial, and industrial projects.

- Temporary event platforms and stages.

- Bridge and infrastructure support scaffolding.

- Maintenance and repair access in various industries.

Conclusion

Manufacturers and suppliers of scaffolding tubes in Canada provide durable, high-quality tubing essential for safe and efficient scaffolding structures. Top companies like Scaffold Depot, Layher North America, Canada Scaffold Supply, Safetech Scaffold Ltd., and Urban Scaffolding Ltd. employ state-of-the-art manufacturing processes that meet strict Canadian standards and environmental conditions. Through rigorous quality control, innovative surface treatment, and a variety of material choices, these manufacturers ensure their scaffolding tubes perform reliably across a broad range of applications.

For international OEM partners, wholesalers, and brand owners looking for trustworthy and quality scaffolding tube suppliers in Canada, these manufacturers offer expert solutions with customization capabilities and timely delivery, supporting the construction industry's growth and safety demands nationwide.

FAQ

1. What are the standards for scaffolding tubes in Canada?

CSA G40.21 and ASTM A53 set specifications for steel and aluminum scaffolding tubes, including strength, dimension, and coating requirements.

2. What materials are scaffolding tubes commonly made from?

High-tensile carbon steel, galvanized steel, aluminum, and stainless steel.

3. How is corrosion prevented in scaffolding tubes?

Through hot-dip galvanizing, powder coating, or using inherently corrosion-resistant materials like aluminum or stainless steel.

4. Can scaffolding tubes be custom manufactured?

Yes, manufacturers offer custom sizes, coatings, and lengths to meet specific project specifications.

5. What are the advantages of aluminum scaffolding tubes?

They're lightweight, easy to transport and assemble, and resistant to corrosion without additional coatings.