Content Menu

● The Japanese Advantage in Scaffolding Tube Manufacturing

● Leading Scaffolding Tube Manufacturers and Suppliers in Japan

>> Sugiko Group: Pioneer Since 1953 with Extensive Offerings

>> SANKYO Corporation: Innovators of Kwikstage and Frame Systems

>> KYC Machine Industry Co., Ltd.: Precision and Lightweight Solutions

>> IWATA Co., Ltd.: Quality Subsidiary of Takamiya Group

>> Nisso Industries Co., Ltd.: Safety and Durability Experts

>> Shinwa Co., Ltd.: Large Scale Manufacturer with Sustainable Practices

● Why Choose Japanese Scaffolding Tube Manufacturers and Suppliers?

● Conclusion

● FAQ

>> 1. What certifications should I look for when sourcing scaffolding tubes from Japan?

>> 2. Do Japanese manufacturers offer customization for scaffolding tubes?

>> 3. What are the common types of scaffolding tubes and systems produced in Japan?

>> 4. Are Japanese scaffolding products mainly intended for domestic use or export?

>> 5. How is quality ensured by Japanese scaffolding tube manufacturers?

Japan's manufacturing sector is globally renowned for its precision, high-quality materials, and cutting-edge technology, making it a powerhouse in producing reliable and innovative scaffolding systems. Among these, scaffolding tube manufacturers and suppliers in Japan have carved a niche by offering sturdy, customizable, and certified products tailored to domestic and international construction needs.This article delves into the top Japanese scaffolding tube manufacturers and suppliers, exploring their product lines, quality control practices, technological innovations, and why they are trusted partners for OEM services by foreign brands, wholesalers, and manufacturers worldwide.

The Japanese Advantage in Scaffolding Tube Manufacturing

Japanese manufacturers achieve excellence in producing scaffolding tubes through rigorous adherence to national and international quality standards such as JIS G3444 and JIS G3445, which govern mechanical strength, dimensional accuracy, and corrosion resistance.

Typical manufacturing processes include:

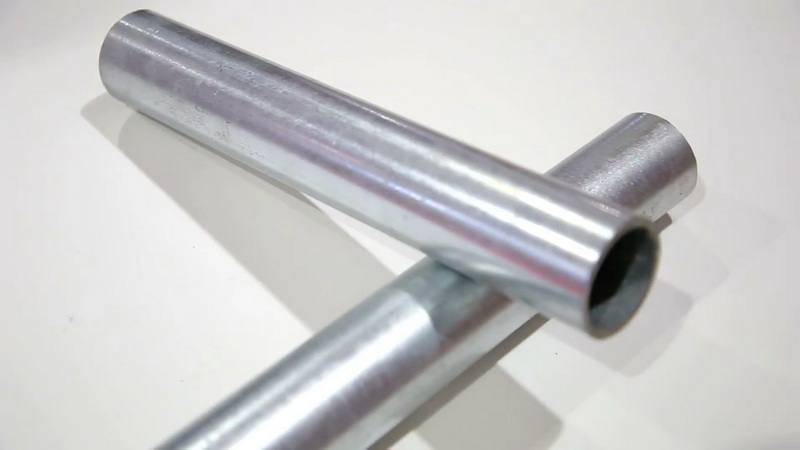

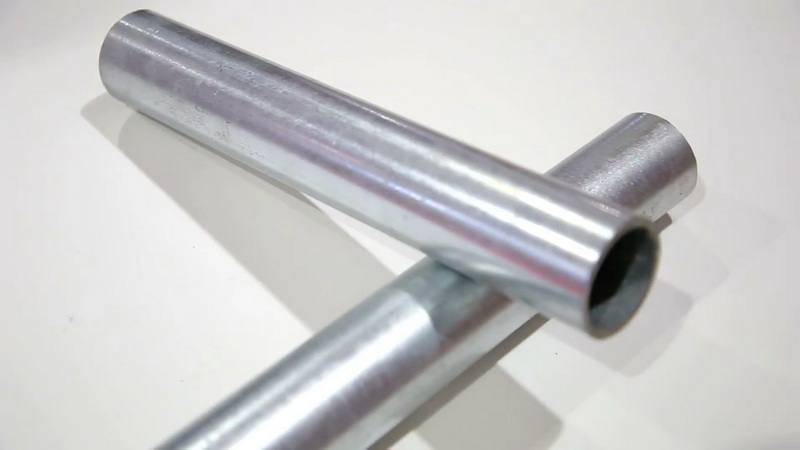

- Cold-forming and Electric Resistance Welding (ERW): For shaping carbon steel tubes with precision.

- Hot-dip Galvanizing: Applied extensively to ensure long-lasting corrosion protection.

- Strict Dimensional Control: To maintain tight tolerances required for safety and interoperability.

Many manufacturers also produce aluminum tubing alternatives to offer lighter scaffolding solutions suitable for temporary or mobile projects requiring ease of assembly.

In addition to producing high-quality scaffolding tubes, Japanese suppliers emphasize comprehensive product ranges that include couplers, clamps, adjustable bases, platform accessories, and safety systems such as netting and guardrails, enabling integrated scaffolding solutions.

With a strong focus on sustainability, Japanese companies have introduced eco-friendly galvanizing technologies and longer-lasting protective coatings, helping projects reduce maintenance costs and minimize environmental impacts.

Leading Scaffolding Tube Manufacturers and Suppliers in Japan

The following companies stand out for their innovation, quality, and reliability in the Japanese scaffolding tube market:

Sugiko Group: Pioneer Since 1953 with Extensive Offerings

Founded in 1953 and headquartered in Yokohama, Sugiko Group is a stalwart of Japan's scaffolding industry. Their expansive distribution network spans Tokyo, Osaka, Aichi, and beyond.

Sugiko's product portfolio includes:

- Ringlock Scaffolding

- Frame Scaffolding

- Modular Staircases

- Toe Boards and Diagonal Braces

Their scaffolding tubes are fabricated with premium steel, meeting rigorous JIS standards and ensuring superior durability and load-bearing performance. Sugiko also provides engineering consultation and on-site technical support to OEM clients and contractors.

SANKYO Corporation: Innovators of Kwikstage and Frame Systems

Established in 1972 in Osaka, SANKYO Corporation specializes in Kwikstage and frame scaffolding, with a reputation for safety-focused walk-through systems and efficient modular designs.

Their business extends to:

- Scaffolding tube sales

- Safety netting supply

- Accessory and clamp manufacturing

- Rental and installation services

SANKYO's commitment to safety and compliance makes them popular for both commercial and infrastructure projects.

KYC Machine Industry Co., Ltd.: Precision and Lightweight Solutions

Based in Osaka and founded in 1971, KYC Machine Industry produces ringlock scaffolding, steel pipes, and aluminum planks emphasizing mechanical robustness alongside lighter scaffolding options.

They serve major cities such as Tokyo and Hiroshima, providing nationwide distribution and technical services.

IWATA Co., Ltd.: Quality Subsidiary of Takamiya Group

Operating out of Wakayama, IWATA Co., Ltd. focuses on ringlock, frame, and ladder scaffolding. As part of the Takamiya Group, IWATA offers stringent quality controls ensuring compliance with Japanese standards.

Their products serve a wide range of construction and maintenance applications.

Nisso Industries Co., Ltd.: Safety and Durability Experts

With 50 years of experience headquartered in Tokyo, Nisso Industries supplies:

- Facade frame scaffolding

- Toe boards

- Ringlock and frame scaffolding systems

Their comprehensive testing standards assure strong load capacity and long product lifespan, supporting civil engineering and commercial infrastructure projects.

Shinwa Co., Ltd.: Large Scale Manufacturer with Sustainable Practices

Shinwa Co., Ltd., based in Gifu, employs over 160 staff and specializes in ringlock, kwikstage, and tubular scaffolding systems alongside accessories like couplers and steel pallets.

They prioritize sustainable manufacturing methods increasing the lifespan of scaffolding materials and promoting environmental stewardship.

Why Choose Japanese Scaffolding Tube Manufacturers and Suppliers?

Collaborating with Japanese scaffolding tube manufacturers and suppliers offers the following benefits for international partners:

- Certified Quality: Products meet rigorous JIS standards (G3444 & G3445), with many also conforming to relevant EN certifications.

- Customization & OEM Flexibility: Many suppliers tailor tube sizes, wall thicknesses, galvanizing, and fittings to precise OEM specifications.

- Innovative Solutions and Sustainability: Advanced galvanizing and coating technologies extend product life and reduce maintenance.

- Comprehensive Product Lines: Offerings include tubes, couplers, stairs, walkways, guardrails, and safety accessories.

- Technical Support and After-Sales Service: Manufacturers provide engineering consulting, training, installation services, and spare parts logistics.

- Global Reach: While serving a strong domestic market, many Japanese companies export globally, supporting diverse international construction needs.

Conclusion

Japan's scaffolding tube manufacturers and suppliers possess decades of expertise, world-class technology, and strong quality control to create scaffolding tubes and systems renowned for durability, safety, and versatility. Leaders such as Sugiko Group, SANKYO Corporation, KYC Machine Industry, IWATA Co., Ltd., Nisso Industries, and Shinwa Co., Ltd. offer foreign brands and wholesalers reliable OEM partnerships backed by innovation and compliance with Japan's strict standards.

Choosing Japanese manufacturers means securing scaffolding tubes and systems that meet the highest global safety and environmental standards — essential for managing rigorous construction projects efficiently and safely worldwide.

FAQ

1. What certifications should I look for when sourcing scaffolding tubes from Japan?

Ensure compliance with JIS G3444 and JIS G3445 standards for mechanical strength, dimensional accuracy, and corrosion resistance. Many manufacturers also comply with EN 39 and other international standards. Certificates like ISO 9001 for quality management may also be provided.

2. Do Japanese manufacturers offer customization for scaffolding tubes?

Yes, Japanese suppliers typically provide customization regarding tube diameters, thickness, galvanizing grades, and fittings tailored to customer and OEM requirements. Custom engineering support is often available.

3. What are the common types of scaffolding tubes and systems produced in Japan?

Key systems include:

- Ringlock scaffolding

- Kwikstage scaffolding

- Frame scaffolding

- Tubular scaffolding with clamp fittings

Additionally, accessories such as modular stairs, toe boards, and safety nets are also produced.

4. Are Japanese scaffolding products mainly intended for domestic use or export?

Japanese products cater to both domestic and international markets. The high standards and certifications ensure suitability for global construction projects.

5. How is quality ensured by Japanese scaffolding tube manufacturers?

Quality is ensured using premium-grade steel compliant with JIS standards, advanced ERW welding processes, hot-dip galvanizing for corrosion protection, in-house testing, and quality inspections, alongside experienced technical staff managing production.