Content Menu

● Overview of the UK Scaffolding Tube Market

● Leading Scaffolding Tube Manufacturers and Suppliers in the UK

>> Tata Steel

>> British Steel

>> NSG Group UK

>> Acme Scaffolding Supplies Ltd.

>> Steel Tubes UK

● Types and Features of UK Scaffolding Tubes

● Manufacturing Processes and Quality Standards

● OEM Services and Customization in UK Tube Manufacturing

● Industry Trends and Innovations in the UK

● Conclusion

● FAQ

>> 1. What are the common sizes and types of scaffolding tubes produced in the UK?

>> 2. Which standards do UK scaffolding tubes comply with?

>> 3. Do UK manufacturers offer OEM services for scaffolding tubes?

>> 4. What surface treatments are typical for scaffolding tubes in the UK?

>> 5. How do UK manufacturers ensure the quality and safety of scaffolding tubes?

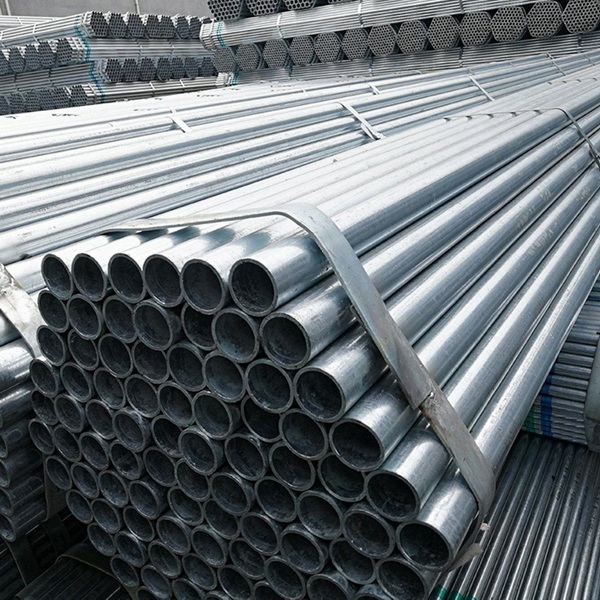

Scaffolding tubes are critical components in the construction and maintenance industries, providing the structural framework on which scaffolding is built. The UK's scaffolding sector is known for its high standards of safety and quality, supported by a network of reputable scaffolding tube manufacturers and suppliers. These companies produce tubes that meet rigorous British and European standards, offering a variety of sizes, materials, and finishes suited for all types of scaffolding projects, from residential to industrial.This article provides an in-depth look at the top scaffolding tube manufacturers and suppliers in the UK, underlining their product ranges, certifications, technological advancements, and OEM manufacturing services.

Overview of the UK Scaffolding Tube Market

The significance of scaffolding tubes in providing safe, stable structures in construction projects has driven continuous improvements in the UK market. UK manufacturers produce scaffolding tubes that comply with British Standards BS EN 39 and EN 10255, which govern the dimensions, mechanical properties, and testing requirements for steel tubes designed specifically for scaffolding applications.

UK scaffolding tubes must demonstrate high tensile strength, corrosion resistance, and dimensional consistency to guarantee structural stability and worker safety. To enhance durability, suppliers apply surface treatments such as hot-dip galvanizing and cold finish welding, which prolong tube lifespan, especially in demanding weather conditions prevalent in the UK.

Environmental sustainability is another focus area, with many manufacturers using recycled steel and implementing energy-efficient production methods to reduce their carbon footprint. Additionally, the ongoing modernization of production facilities with automation and digital process control delivers higher quality tubes with consistent performance.

The UK's strategic location and advanced industrial infrastructure allow manufacturers to stay responsive to evolving global regulations and market needs, strengthening their export capabilities and OEM partnerships. As the global construction industry increasingly demands safer and more environmentally friendly products, UK manufacturers adapt by innovating in materials, coatings, and manufacturing processes.

Leading Scaffolding Tube Manufacturers and Suppliers in the UK

Tata Steel

Tata Steel is one of the UK's leading producers of steel scaffolding tubes, known for manufacturing products that strictly meet BS EN 39 and EN 10255 standards. Their tubes are made with advanced hot-rolled steel processing and undergo stringent quality assurance at UK-based facilities. Tata Steel offers various tube sizes and surface finishes, including zinc and polyester coatings, to match different environmental and structural requirements.

Tata supports OEM collaborations by advising customers on suitable tube specifications and application-specific customizations, fostering partnerships with major scaffold manufacturers and suppliers.

British Steel

British Steel manufactures a broad selection of scaffolding tubes that are renowned for their strength, quality, and compliance with UK and European standards. Their portfolio includes both seamless and welded steel tubes, ensuring uncompromised structural integrity for a wide range of scaffolding uses.

They also provide customized solutions varying in diameter, wall gauge, and finishes such as hot-dip galvanizing and powder coating. British Steel's capacity to provide large volumes suits the needs of wholesalers, rental companies, and scaffold fabricators.

NSG Group UK

NSG Group excels in the production of high-performance scaffolding tubes, integrating material science advancements to enhance corrosion resistance and durability, particularly for applications in corrosive or harsh environments such as coastal developments and chemical plants.

Certified to ISO 9001, NSG employs automated manufacturing and rigorous testing ensuring consistently high product quality. They offer OEM production and private label tubing solutions tailored for international clients and scaffold system integrators.

Acme Scaffolding Supplies Ltd.

Acme Scaffolding Supplies focuses on standard 48.3mm diameter scaffolding tubes conforming to BS EN 39. Their product range includes galvanized, black steel, and specialized heavy-duty tubes suited for various scaffold roles.

Acme provides scalable supply solutions, supporting both small-scale contractors and larger service providers with flexible order quantities and reliable delivery schedules within the UK.

Steel Tubes UK

Steel Tubes UK is a comprehensive supplier of steel scaffolding tubes, serving modular and traditional scaffolding markets throughout the UK. Their tubes meet all relevant British and European standards, offering resistance to corrosion suitable for long-term outdoor use.

With a strong emphasis on customer service, Steel Tubes UK provides tailored consultancy on tube specification and OEM options, ensuring clients receive products that align perfectly with their scaffolding system requirements.

Types and Features of UK Scaffolding Tubes

UK scaffolding tube manufacturers typically produce a diverse array of tube types to suit different applications:

- Standard Scaffolding Tubes: These have a 48.3mm outer diameter and wall thickness ranging from 3.2mm to 5.0mm, produced through hot-rolled or cold-formed steel processing. They fulfill the general structural needs of most scaffolding systems.

- Galvanized Tubes: Featuring either hot-dip or electro-galvanized coatings, these tubes provide essential protection against rust and deterioration, crucial for outdoor scaffolds exposed to moisture and chemical exposure.

- Black Steel Tubes: These untreated tubes are often used for short-term scaffolds in dry or indoor environments where corrosion is less of a concern.

- Heavy-Duty Tubes: With thicker walls and increased tensile strength, these tubes are designed for scaffolding structures bearing heavier loads such as bridges, power plants, and industrial facilities.

- Specialty Tubes: These include tubes manufactured from high-tensile steel alloys or with added chemical resistance, suitable for specialized scaffolding systems that require optimum strength-to-weight ratios.

Lengths are commonly standardized at 6 or 7 meters but can be customized based on project requirements. Tubes may also be supplied in cut-to-length orders for OEM clients working on pre-engineered scaffolding solutions.

Manufacturing Processes and Quality Standards

Scaffolding tube production in the UK follows several rigorous steps to ensure top quality and safety compliance:

- Material Selection: Manufacturers start with steel billets or coils meeting chemical composition and mechanical specifications.

- Tube Forming: Steel is shaped into tubes by either continuous welding of cold-formed steel strip or by seamless extrusion. Welded tubes undergo automated welding, followed by surface finishing.

- Heat Treatment: Tubes are heat treated to achieve the required tensile strength and ductility, typically over 415 N/mm² tensile strength.

- Surface Treatment: Hot-dip galvanizing coats the tube with a thick, corrosion-resistant zinc layer. Electro-galvanizing and powder coating options provide alternative protective finishes.

- Cutting and Inspection: Tubes are cut to length, then undergo dimensional verification and mechanical testing, including tensile strength, elongation, and bend tests.

UK scaffolding tubes comply with:

- BS EN 39: The primary European standard governing tubes for scaffolding, covering dimensional and mechanical requirements.

- BS EN 10255: Establishes mechanical properties for tubes intended for mechanical and structural uses.

- ISO 9001: Ensures a stringent quality management system governs all production stages.

- NASC and Constructionline Registration: Many manufacturers maintain these accreditations to affirm their commitment to industry best practices and safety standards.

OEM Services and Customization in UK Tube Manufacturing

OEM manufacturing is a vital component of the UK scaffolding tube market. Services commonly provided include:

- Customized diameters, wall thicknesses, and tube lengths to suit bespoke scaffolding design needs.

- Tailored surface coatings including specific galvanizing thickness, powder coating colors, and specialized corrosion protections.

- Private labeling, customized packaging, and brand embossing options to match client marketing requirements.

- Flexible production runs accommodating both prototype developments and mass production orders.

UK manufacturers also offer expert technical support, assisting OEM clients with product design advice, compliance verification, and post-sale support including testing and certification documents.

Efficient logistics services ensure prompt delivery to assembly facilities, rental companies, and distributors within the UK and internationally.

Industry Trends and Innovations in the UK

The UK scaffolding tube industry has seen several recent developments:

- Use of advanced high-strength steel alloys allowing lighter but stronger scaffolding tubes, reducing overall scaffold weight without compromising safety.

- Enhanced galvanizing and coating processes that improve corrosion resistance and extend product lifetimes particularly in coastal or industrial environments.

- Automation and robotics in tube production improving manufacturing precision, consistency, and throughput.

- Greater emphasis on environmentally sustainable practices including steel recycling programs and energy-efficient production lines.

- Increased integration of digital tracking through QR codes and RFID tagging to improve supply chain transparency and product authentication.

Manufacturers are also innovating regarding tube compatibility with modular scaffold systems, enabling faster erection with fewer components while maintaining flexibility across diverse construction projects.

Conclusion

The UK is home to world-class scaffolding tube manufacturers and suppliers who combine advanced production technologies with rigorous quality standards such as BS EN 39 and EN 10255. Companies like Tata Steel, British Steel, and NSG Group offer a wide range of tubes that meet diverse construction needs, backed by comprehensive OEM services and supply chain reliability.

Continuous innovation in material science, coating technologies, and sustainable manufacturing cements the UK's position as a global leader in scaffolding tube production. Whether for residential, commercial, or industrial scaffolding, UK-made scaffolding tubes provide trusted strength, durability, and compliance for safe, efficient construction worldwide.

FAQ

1. What are the common sizes and types of scaffolding tubes produced in the UK?

Commonly produced tubing includes 48.3mm diameter tubes with wall thicknesses from 3.2mm to 5mm, available in galvanized, black steel, heavy-duty, and specialty grades.

2. Which standards do UK scaffolding tubes comply with?

UK tubes generally comply with BS EN 39, BS EN 10255, ISO 9001, and many suppliers also have NASC registration for industry safety compliance.

3. Do UK manufacturers offer OEM services for scaffolding tubes?

Yes, OEM services including custom sizing, surface treatments, packaging, and branding are offered to accommodate both small and large-scale orders.

4. What surface treatments are typical for scaffolding tubes in the UK?

Hot-dip galvanizing is most common for corrosion resistance, followed by electro-galvanizing, zinc plating, and powder coatings for specific applications.

5. How do UK manufacturers ensure the quality and safety of scaffolding tubes?

Quality is ensured through strict raw material controls, automated manufacture, rigorous mechanical testing, certification by UKAS-approved labs, and adherence to UK and European standards.