Content Menu

● Understanding Scaffolding Walk Thru Frames

● Leading Scaffolding Walk Thru Frame Manufacturers and Suppliers in Europe

>> 1. Wellmade Scaffold – OEM Partner with European Standards

>> 2. Layher Group – Europe's Premier Scaffolding Manufacturer

>> 3. Plettac – Trusted European Scaffolding Supplier

>> 4. Layher-Style OEM Frames from China for European Market

>> 5. Scaffold Express Europe – Supplier of Quality Walk Thru Frames

● Key Features and Standards of European Scaffolding Walk Thru Frames

>> Material and Finish

>> Dimensions and Compatibility

>> Safety Compliance

>> Customization and OEM Options

>> Accessories

● Market Trends and Innovations in Europe

>> Lightweight and Modular Systems

>> Enhanced Safety Features

>> Sustainability Initiatives

>> Digitalization and Smart Scaffolding

● Conclusion

● FAQ

>> 1. What are the typical dimensions of scaffolding walk thru frames used in Europe?

>> 2. Are European scaffolding walk thru frames compatible with frames from other regions?

>> 3. What materials and finishes are preferred for European walk thru frames?

>> 4. Can I customize scaffolding walk thru frames for my European brand?

>> 5. What safety standards do European scaffolding walk thru frames comply with?

Scaffolding walk thru frames are vital components in the construction industry, enabling safe and efficient access for workers on various job sites. In Europe, where construction standards are stringent and safety regulations rigorous, selecting reliable scaffolding walk thru frame manufacturers and suppliers is essential for contractors, wholesalers, and brand owners. This article provides an in-depth overview of the top scaffolding walk thru frame manufacturers and suppliers in Europe, highlighting product features, compliance with European standards, customization options, and emerging market trends. As a Chinese scaffolding materials manufacturer specializing in OEM services for foreign brands, we also emphasize how international cooperation enhances product quality and availability in the European market.

Understanding Scaffolding Walk Thru Frames

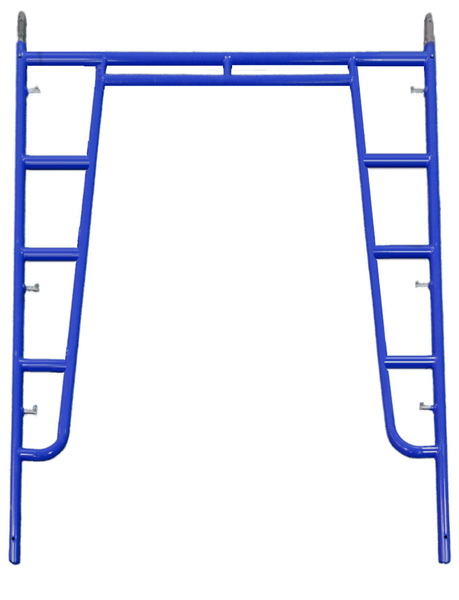

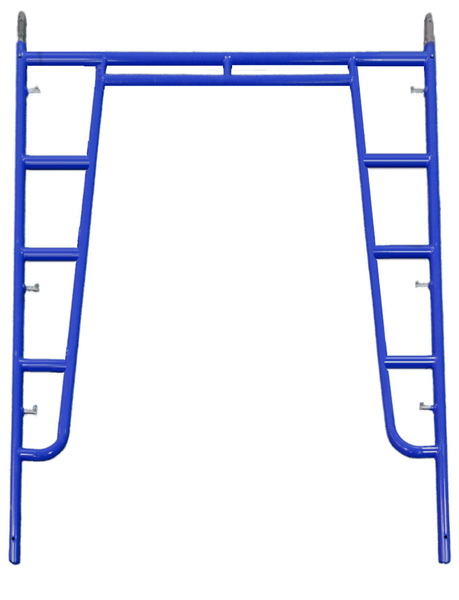

Scaffolding walk thru frames are structural scaffold components designed to create safe passageways within scaffolding systems. Typically, these frames measure around 42 inches (1.07m) to 5 feet (1.52m) in width and approximately 6 feet 4 inches (1.93m) to 6 feet 8 inches (2.03m) in height. Their primary function is to allow workers and materials to pass through scaffolding easily while maintaining structural integrity and safety.

In Europe, walk thru frames often conform to the EN 12810 and EN 12811 standards, ensuring high safety, durability, and compatibility with other scaffolding components. These frames are widely used in masonry, plastering, facade work, and general construction projects.

Leading Scaffolding Walk Thru Frame Manufacturers and Suppliers in Europe

1. Wellmade Scaffold – OEM Partner with European Standards

Wellmade Scaffold, a leading Chinese manufacturer, supplies a comprehensive range of scaffolding frames tailored for the European market. Their products include walk thru frames, mason frames, ladder frames, shoring frames, and more, all manufactured according to ISO 9001, CE certification, and conforming to EN 12810 and EN 12811 standards.

Wellmade produces walk thru frames with European-standard outer diameter scaffold tubes (O.D 48.3mm), which differ from traditional 42mm tubes used in other regions. Their frames come in various sizes such as 3'x6'8” (approx. 0.9m x 2.03m) and 5'x6'4” (1.52m x 1.93m), with powder coating or galvanization finishes for enhanced corrosion resistance.

OEM services offered by Wellmade include custom logos, color coatings, and tailored dimensions, making them a preferred partner for European brand owners and wholesalers.

2. Layher Group – Europe's Premier Scaffolding Manufacturer

Layher is a renowned German scaffolding manufacturer known for its high-quality walk thru frames and modular scaffolding systems. Their products comply with all relevant European safety standards and are widely used across Europe and beyond.

Layher walk thru frames feature robust steel construction with precision engineering, designed for quick assembly and disassembly. Their frames typically use 48.3mm diameter tubes and come with proprietary locking mechanisms ensuring maximum safety and reliability.

3. Plettac – Trusted European Scaffolding Supplier

Plettac, a subsidiary of Altrad Group, is another key player in the European scaffolding market. Their walk thru frames are designed to meet the demands of heavy-duty construction projects, offering excellent load-bearing capacity and compliance with EN standards.

Plettac frames typically feature hot-dip galvanized finishes and innovative locking pins for enhanced safety. Their walk thru frames are compatible with various scaffold systems, making them versatile for different construction needs.

4. Layher-Style OEM Frames from China for European Market

Many European suppliers source OEM scaffolding walk thru frames from Chinese manufacturers like Wellmade, who produce Layher-style frames with exact specifications. These frames meet CE certification and EN standards and are offered at competitive prices.

OEM cooperation allows European wholesalers and brand owners to offer cost-effective, high-quality scaffolding frames with custom branding and finishes. This synergy supports the growing demand for scaffolding walk thru frames in Europe's bustling construction sector.

5. Scaffold Express Europe – Supplier of Quality Walk Thru Frames

Scaffold Express Europe supplies a broad range of scaffolding components, including walk thru frames designed for European construction projects. Their products emphasize compliance with safety standards and ease of use.

They offer frames in various sizes, finishes, and locking mechanisms, catering to contractors' diverse needs. Scaffold Express Europe is known for fast delivery and excellent customer support.

Key Features and Standards of European Scaffolding Walk Thru Frames

Material and Finish

European scaffolding walk thru frames are typically manufactured from high-strength steel tubes with an outer diameter of 48.3mm, providing superior strength and stability. Finishes include hot-dip galvanization for long-term corrosion resistance and powder coating for aesthetic appeal and protection.

Dimensions and Compatibility

Standard European walk thru frames measure approximately 0.73m to 1.52m in width and 1.93m to 2.03m in height. The frames are designed to be compatible with modular scaffolding systems, allowing seamless integration with braces, planks, and accessories.

Safety Compliance

Frames conform to EN 12810 and EN 12811 standards, which regulate load capacity, structural integrity, and safety features such as locking pins and anti-slip cross braces. This compliance ensures worker safety and legal adherence on European construction sites.

Customization and OEM Options

European suppliers often collaborate with OEM manufacturers to provide customized scaffolding walk thru frames. Options include:

- Custom colors and branding

- Specific dimensions tailored to project requirements

- Different locking pin styles (flip lock, drop lock, fast lock)

- Lightweight aluminum alternatives for interior or mobile scaffolding

Accessories

Common accessories include scaffold lock pins, roll pins, gravity lock pins, spring pins, rivet pins, and span pins, all designed to enhance safety and ease of assembly.

Market Trends and Innovations in Europe

Lightweight and Modular Systems

The European construction industry increasingly favors lightweight, modular scaffolding systems that reduce labor costs and improve efficiency. Aluminum frames and foldable designs are gaining popularity for interior and mobile scaffolding applications. These innovations allow faster setup and breakdown, reducing downtime and labor expenses.

Enhanced Safety Features

Manufacturers are integrating safety enhancements such as anti-slip coatings, ergonomic locking mechanisms, and integrated guardrails to reduce accidents and improve compliance with stringent European safety laws. The development of quick-locking pins and self-locking mechanisms has made assembly safer and more efficient.

Sustainability Initiatives

Environmental concerns drive the adoption of eco-friendly coatings and recycling initiatives in scaffolding production. Hot-dip galvanization processes are optimized to minimize waste, and manufacturers emphasize sustainable sourcing of raw materials. Some companies are exploring the use of recycled steel and environmentally friendly powder coatings to reduce their carbon footprint.

Digitalization and Smart Scaffolding

Emerging trends in digitalization are influencing scaffolding manufacturing and supply. Some manufacturers are incorporating RFID tags and QR codes on scaffolding components, including walk thru frames, to enable better inventory management, tracking, and safety inspections. This smart scaffolding approach enhances project management and reduces errors on site.

Conclusion

The European scaffolding market is supported by a combination of established domestic manufacturers such as Layher and Plettac, alongside trusted OEM suppliers like Wellmade from China. These manufacturers and suppliers provide high-quality, compliant, and customizable scaffolding walk thru frames that meet the rigorous demands of European construction projects. With a focus on safety, durability, and innovation, European contractors and wholesalers can rely on these manufacturers for efficient and reliable scaffolding solutions. OEM partnerships further enhance product availability and customization, allowing foreign brands to compete effectively in the European market. By understanding the features, standards, and trends, stakeholders can make informed decisions to optimize scaffolding procurement and project safety.

FAQ

1. What are the typical dimensions of scaffolding walk thru frames used in Europe?

European walk thru frames generally measure between 0.73m to 1.52m in width and 1.93m to 2.03m in height, designed to fit modular scaffolding systems.

2. Are European scaffolding walk thru frames compatible with frames from other regions?

Many European frames use 48.3mm diameter tubes, which differ from the 42mm tubes common in other regions. However, OEM manufacturers produce compatible frames to meet European standards, enabling cross-regional compatibility.

3. What materials and finishes are preferred for European walk thru frames?

High-strength steel with hot-dip galvanization or powder coating is standard to ensure durability, corrosion resistance, and compliance with European safety standards.

4. Can I customize scaffolding walk thru frames for my European brand?

Yes, many manufacturers and suppliers offer OEM services that include custom logos, colors, dimensions, and locking pin types to suit specific brand and project requirements.

5. What safety standards do European scaffolding walk thru frames comply with?

European walk thru frames comply with EN 12810 and EN 12811 standards, which regulate load capacity, structural integrity, and safety features to ensure worker protection.