Content Menu

● What is Shoring Frame Scaffolding?

● Leading Shoring Frame Scaffolding Manufacturers and Suppliers in America

>> 1. Layher North America

>> 2. Vanguard Manufacturing

>> 3. ScaffoldMart

>> 4. American Scaffold

>> 5. AAIT Scaffold

>> 6. Wellmade Group (China OEM Supplier)

● Market Trends and Innovations

● Applications of Shoring Frame Scaffolding in America

● Why Choose OEM Shoring Frame Scaffolding Manufacturers and Suppliers?

● How to Select the Right Shoring Frame Scaffolding Manufacturer or Supplier

● Enhancing Safety and Efficiency with Shoring Frame Scaffolding

● Environmental Considerations in Shoring Frame Scaffolding

● The Future of Shoring Frame Scaffolding in America

● Conclusion

● FAQ

>> 1. What are the advantages of shoring frame scaffolding compared to other systems?

>> 2. What certifications should I look for in shoring frame scaffolding manufacturers?

>> 3. Can OEM suppliers from China provide shoring frame scaffolding that meets American standards?

>> 4. How do digital tools benefit shoring frame scaffolding projects?

>> 5. What types of shoring frame scaffolding are commonly used in America?

Shoring frame scaffolding is a cornerstone of the American construction industry, providing essential temporary support for structures during building, renovation, and repair. As the demand for safe, efficient, and cost-effective solutions grows, the role of shoring frame scaffolding manufacturers and suppliers becomes increasingly vital. This article explores the leading shoring frame scaffolding manufacturers and suppliers in America, highlights the latest industry trends, and provides a comprehensive guide for contractors, wholesalers, and OEM partners seeking reliable solutions.

What is Shoring Frame Scaffolding?

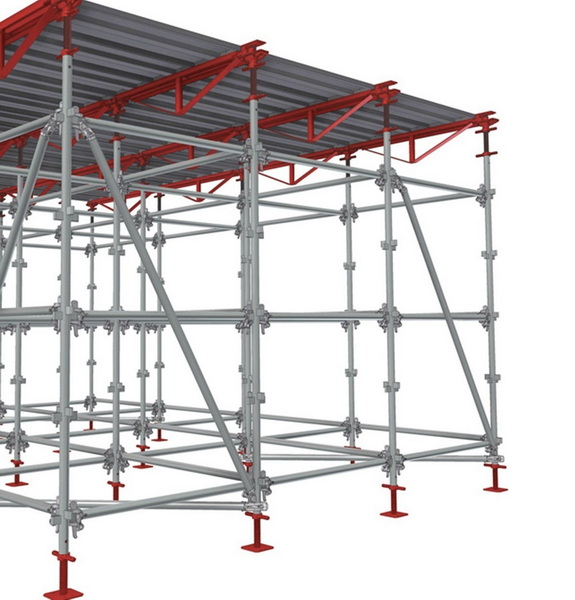

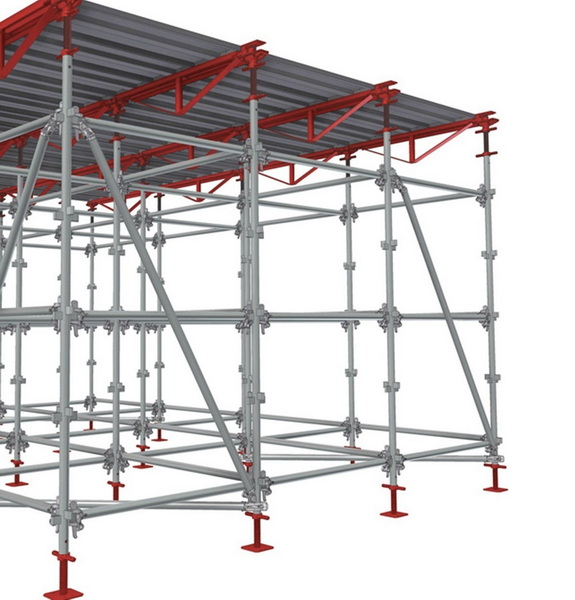

Shoring frame scaffolding is a modular system designed to support heavy loads and stabilize structures during construction or repair. It consists of prefabricated steel or aluminum frames, cross braces, and accessories that can be quickly assembled and dismantled. Shoring frames are engineered to meet stringent safety standards, making them indispensable for projects ranging from high-rise buildings to bridges and industrial plants.

Key Features:

- High Load Capacity: Supports slabs, beams, and walls during construction.

- Modular Design: Allows for rapid assembly and adaptability to various project requirements.

- Safety Compliance: Meets OSHA, ANSI, and ASTM standards for worker safety.

- Versatility: Suitable for commercial, residential, industrial, and infrastructure projects.

Leading Shoring Frame Scaffolding Manufacturers and Suppliers in America

1. Layher North America

Layher is a global leader in shoring frame scaffolding manufacturing, known for its innovative designs and robust quality control. Their systems are widely used across the USA and Canada, offering lightweight aluminum and steel frames, shoring towers, and protective scaffolding.

- Certifications: OSHA, ANSI, ASTM, ISO 9001

- Innovations: Digital design support, 3D modeling, and pre-planning services

- Distribution: Multiple warehouses for fast delivery

2. Vanguard Manufacturing

Vanguard specializes in high-quality steel scaffold frames and accessories, including shoring frames. Their products are recognized for precision welding, robust construction, and long-term reliability. Vanguard offers both sales and rental options, with responsive customer support.

3. ScaffoldMart

ScaffoldMart manufactures and supplies premium-grade alloy shoring frames, focusing on quality, durability, and fast delivery. Their frames are crafted using high-strength alloy and undergo rigorous quality control to ensure perfect fit and easy assembly.

4. American Scaffold

American Scaffold is a premier supplier specializing in industrial and shipyard scaffolding solutions. They offer comprehensive shoring and containment systems tailored for maritime, industrial, and commercial projects, with a large inventory and nationwide presence.

5. AAIT Scaffold

AAIT Scaffold is a global supplier with a strong presence in the USA, offering a wide selection of shoring frame scaffolding components and accessories. Their strategic warehousing ensures fast delivery, and their products are known for reliability and compliance with safety standards.

6. Wellmade Group (China OEM Supplier)

Wellmade Group is a prominent Chinese OEM manufacturer supplying shoring frame scaffolding to the American market. They offer a comprehensive range of frames, including walk-through, mason, ladder, and shoring frames, all compliant with ISO 9001, CE, OSHA, ANSI, and CSA standards. Wellmade provides OEM branding, packaging, and tailored solutions for American brands and wholesalers.

Market Trends and Innovations

- Material Innovation: Increasing use of lightweight aluminum frames for easier handling and transport.

- Digital Integration: Adoption of BIM (Building Information Modeling), 3D modeling, and augmented reality for scaffold design and planning.

- Safety Enhancements: Improved locking mechanisms, ergonomic frame designs, and comprehensive training programs.

- Sustainability: Eco-friendly galvanizing processes and recycling initiatives.

- Modular Flexibility: Systems designed for rapid assembly and adaptability to complex project requirements.

- OEM Partnerships: Growing collaboration with Chinese OEM suppliers ensures cost-effective, quality products meet American standards.

Applications of Shoring Frame Scaffolding in America

Shoring frame scaffolding is used in a wide range of sectors:

- Residential and Commercial Construction: Façade scaffolding, interior access, and renovations.

- Industrial Maintenance: Platforms for factories, power plants, and refineries.

- Infrastructure Projects: Bridges, tunnels, and highways requiring robust temporary structures.

- Event Staging: Temporary platforms, grandstands, and stages.

- Shipbuilding and Repair: Safe working platforms in shipyards and dry docks.

Why Choose OEM Shoring Frame Scaffolding Manufacturers and Suppliers?

OEM (Original Equipment Manufacturer) partnerships allow American brands, wholesalers, and contractors to access high-quality, customizable shoring frame scaffolding at competitive prices. Chinese OEM suppliers like Wellmade Group offer:

- Customization: Branding, packaging, and tailored solutions to meet specific market needs.

- Quality Assurance: Compliance with international standards and rigorous testing.

- Cost Efficiency: Competitive pricing without compromising on quality.

- Scalability: Ability to fulfill large orders and adapt to changing project requirements.

How to Select the Right Shoring Frame Scaffolding Manufacturer or Supplier

Key Considerations:

- Certifications: Ensure compliance with OSHA, ANSI, ASTM, and ISO 9001.

- Product Range: Look for suppliers offering a variety of frame types and accessories.

- Quality Control: Check for rigorous testing and quality assurance processes.

- Delivery and Support: Choose suppliers with strategic warehousing and responsive customer service.

- OEM Capabilities: For private label or custom solutions, partner with experienced OEM manufacturers.

Enhancing Safety and Efficiency with Shoring Frame Scaffolding

Safety is paramount in construction, and shoring frame scaffolding plays a critical role in protecting workers and ensuring structural integrity during projects. Modern manufacturers and suppliers emphasize:

- Ergonomic Designs: Frames designed for easy handling reduce worker fatigue and injury risk.

- Advanced Locking Systems: Secure connections prevent accidental disassembly or frame collapse.

- Load Monitoring: Some systems incorporate sensors to monitor load stress in real time.

- Training and Support: Manufacturers often provide training materials, videos, and on-site support to ensure proper scaffold use.

Efficiency gains come from the modular nature of shoring frames, enabling rapid assembly and disassembly, reducing labor costs and project timelines. Additionally, integrated digital tools help plan scaffold layouts to optimize material use and site safety.

Environmental Considerations in Shoring Frame Scaffolding

Sustainability is becoming a key focus for manufacturers and suppliers. Efforts include:

- Recyclable Materials: Use of steel and aluminum that can be recycled at the end of product life.

- Eco-Friendly Coatings: Galvanizing and powder coatings that minimize environmental impact.

- Durability: Producing long-lasting frames reduces waste and replacement frequency.

- Efficient Logistics: Warehousing and distribution strategies that reduce carbon footprint.

By choosing suppliers committed to green practices, contractors contribute to sustainable construction goals.

The Future of Shoring Frame Scaffolding in America

The future of shoring frame scaffolding is shaped by technology, safety, and sustainability. Emerging trends include:

- Smart Scaffolding: Integration of IoT devices for real-time monitoring of structural integrity and worker safety.

- Automation: Use of robotics and drones for scaffold inspection and maintenance.

- Material Advances: Development of composite materials combining strength and lightness.

- Global Collaboration: Increasing partnerships between American companies and international OEMs to leverage innovation and cost advantages.

These advancements promise safer, more efficient, and environmentally responsible scaffolding solutions.

Conclusion

The American shoring frame scaffolding market is supported by a blend of established domestic manufacturers and reliable international OEM suppliers. Leading companies like Layher North America, Vanguard Manufacturing, ScaffoldMart, American Scaffold, and AAIT Scaffold deliver certified, high-quality shoring frame scaffolding systems designed for safety, efficiency, and adaptability. Complementing these are OEM suppliers such as Wellmade Group from China, who provide cost-effective, customizable scaffolding products that meet stringent American standards. The integration of digital technologies, safety enhancements, and sustainability initiatives continues to drive innovation and growth in the industry. By partnering with reputable shoring frame scaffolding manufacturers and suppliers, contractors and wholesalers can ensure the success of their projects with reliable, innovative solutions.

FAQ

1. What are the advantages of shoring frame scaffolding compared to other systems?

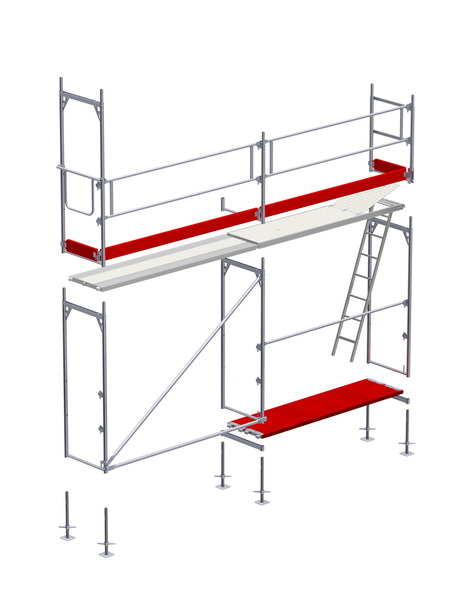

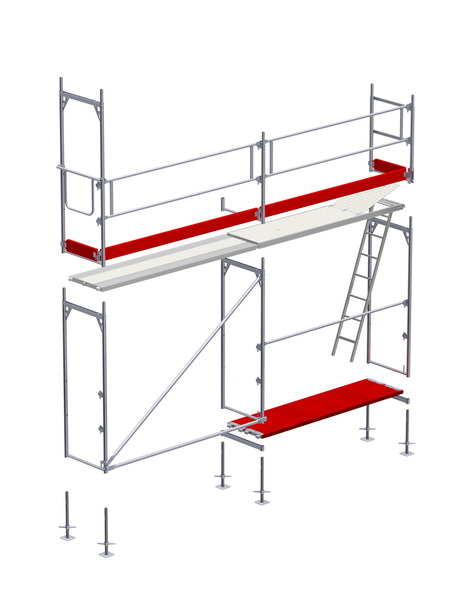

Shoring frame scaffolding offers quick assembly, high load capacity, and modular flexibility, making it ideal for a wide range of construction and industrial applications. Its prefabricated frames and cross braces allow for rapid setup and dismantling, saving time and labor costs.

2. What certifications should I look for in shoring frame scaffolding manufacturers?

Look for compliance with OSHA, ANSI, ASTM standards, and ISO 9001 certification. These certifications ensure that the products meet stringent safety and quality requirements, providing peace of mind for contractors and end-users.

3. Can OEM suppliers from China provide shoring frame scaffolding that meets American standards?

Yes, reputable OEM suppliers like Wellmade Group manufacture shoring frame scaffolding that complies with OSHA, ANSI, ASTM, and ISO standards. They offer customization and competitive pricing, making them a preferred choice for American brands and wholesalers.

4. How do digital tools benefit shoring frame scaffolding projects?

Digital tools such as BIM and 3D modeling enable precise scaffold design, clash detection, and efficient planning. This improves safety, reduces errors, and streamlines project workflows, resulting in better outcomes for contractors and clients.

5. What types of shoring frame scaffolding are commonly used in America?

Common types include walk-through frames, mason frames, ladder frames, shoring frames, and narrow frames. Each type is suited for specific construction or maintenance needs, offering versatility and adaptability for various projects.