Content Menu

● Characteristics of Japanese Frame Scaffolding

● Leading Frame Scaffolding Manufacturers and Suppliers in Japan

>> 1. SUGIKO Group

>> 2. Nisso Industries Co., Ltd

>> 3. KYC Machine Industry Co., Ltd

>> 4. SANKYO Corporation

>> 5. IWATA Co., Ltd

>> 6. Shinwa Co., Ltd

>> 7. DAISAN

● Advanced Manufacturing and Quality Control

● Applications of Japanese Frame Scaffolding

● OEM Services and Customization

● Logistics and Packaging Solutions

● Conclusion

● FAQ

>> 1. What materials are typically used in Japanese frame scaffolding?

>> 2. Are Japanese frame scaffolding manufacturers able to provide OEM services?

>> 3. How does Japanese frame scaffolding ensure safety on construction sites?

>> 4. What advantages does modular frame scaffolding offer?

>> 5. How do Japanese manufacturers maintain high product quality?

Shoring frame scaffolding plays a pivotal role in Japan's construction and industrial sectors, providing safe, modular, and efficient support systems for workers at various heights. Japan is renowned for its advanced manufacturing technologies, rigorous safety standards, and precision engineering, making it home to some of the world's leading shoring frame scaffolding manufacturers and suppliers. This article provides a comprehensive overview of the Japanese frame scaffolding industry, highlighting top manufacturers, product characteristics, manufacturing innovations, OEM services, and logistics solutions. It also addresses frequently asked questions to guide foreign brands, wholesalers, and producers seeking reliable OEM partnerships.

Characteristics of Japanese Frame Scaffolding

Japanese frame scaffolding is designed to meet the demanding requirements of Japan's construction environment. Key features include:

- Materials: Typically made from high-strength steel or lightweight aluminum, treated with hot-dip galvanizing or powder coating to enhance corrosion resistance and durability.

- Design: Modular and walk-through frames generally sized to allow easy worker access, with standard dimensions optimized for safety and efficiency.

- Safety: Incorporates guardrails, toe boards, locking pins, and anti-slip platforms to comply with stringent Japanese and international safety standards such as JIS and ISO.

- Assembly: Components are precision-engineered for quick, tool-free assembly and disassembly, reducing labor time and improving site productivity.

- Durability: Hot-dip galvanizing and advanced surface treatments ensure long service life even in harsh weather conditions.

These features make Japanese frame scaffolding systems highly reliable and adaptable, suitable for a wide range of construction environments.

Leading Frame Scaffolding Manufacturers and Suppliers in Japan

1. SUGIKO Group

- Headquarters: Yokohama, Japan

- Overview: Founded in 1953, SUGIKO Group is a prominent scaffolding manufacturer known for ringlock scaffolding, staircases, toe boards, and frame scaffolding. They operate multiple sales offices across Japan and provide both sales and rental services. Their products are praised for durability and compliance with safety standards.

- Key Products: Ringlock scaffolding, frame scaffolding, staircases, toe boards.

2. Nisso Industries Co., Ltd

- Location: Tokyo, Japan

- Overview: Established over 50 years ago, Nisso Industries specializes in frame scaffolding, facade frames, toe boards, and ringlock scaffolding. Their products are widely used in civil engineering, industrial, and commercial projects, known for excellent load-bearing capacity and wear resistance.

- Key Products: Frame scaffolding, facade frames, toe boards, ringlock scaffolding.

3. KYC Machine Industry Co., Ltd

- Location: Osaka, Japan

- Overview: With over 50 years of experience, KYC Machine Industry manufactures ringlock scaffolding, steel pipes, aluminum steel planks, and frame scaffolding. They emphasize precision machining and high-quality materials.

- Key Products: Ringlock scaffolding, steel pipes, aluminum steel planks, frame scaffolding.

4. SANKYO Corporation

- Location: Osaka, Japan

- Overview: SANKYO Corporation has nearly 50 years of experience and offers Kwikstage scaffolding, frame scaffolding (notably walk-through types), safety nets, and rental and installation services. Their focus on safety and ease of use makes them a trusted supplier.

- Key Products: Kwikstage scaffolding, frame scaffolding, safety nets.

5. IWATA Co., Ltd

- Location: Wakayama Prefecture, Japan

- Overview: A subsidiary of the Takamiya Group, IWATA provides ringlock scaffolding, frame scaffolding, steel scaffolding ledgers, and ladders. Known for detailed product specifications and high-quality manufacturing.

- Key Products: Ringlock scaffolding, frame scaffolding, steel ledgers, ladders.

6. Shinwa Co., Ltd

- Location: Gifu, Japan

- Overview: Established in 1979, Shinwa supplies ringlock, Kwikstage, and tubular scaffolding, along with accessories and steel pallets. They emphasize sustainability and reliability.

- Key Products: Ringlock scaffolding, Kwikstage scaffolding, tubular scaffolding, accessories.

7. DAISAN

- Location: Osaka, Japan

- Overview: Founded in 1975, DAISAN specializes in Kwikstage scaffolding, diagonal braces, and steel planks. They maintain ISO 9001 certification and train professional scaffold engineers to ensure quality and safety.

- Key Products: Kwikstage scaffolding, diagonal braces, steel planks.

Advanced Manufacturing and Quality Control

Japanese shoring frame scaffolding manufacturers employ advanced technologies and stringent quality control processes to ensure product excellence:

- Hot-Dip Galvanizing: Provides superior corrosion resistance, essential for scaffolding exposed to outdoor environments.

- Precision Fabrication: CNC machining and laser cutting guarantee exact dimensions and tight tolerances for easy assembly.

- Automated Welding: Robotic welding ensures consistent weld quality, enhancing structural integrity.

- Material Testing: Rigorous testing of steel and aluminum components for tensile strength, fatigue resistance, and durability.

- ISO and JIS Compliance: Products are certified to meet international and Japanese standards, ensuring safety and reliability.

- Sustainability: Many companies incorporate eco-friendly processes, including recycling steel scrap and reducing emissions during manufacturing.

Applications of Japanese Frame Scaffolding

Japanese frame scaffolding is widely used in:

- Residential and Commercial Construction: Providing safe access and support for building facades, renovations, and new builds.

- Industrial Maintenance: Platforms and shoring for factories, power plants, and refineries.

- Infrastructure Projects: Bridges, tunnels, highways requiring robust temporary structures.

- Event Staging: Temporary platforms, grandstands, and stages for concerts and festivals.

- Shipbuilding and Repair: Working platforms in shipyards and dry docks.

OEM Services and Customization

Japanese manufacturers offer comprehensive OEM services to foreign brands, wholesalers, and producers, including:

- Custom Designs: Tailored scaffolding solutions to meet specific project or market requirements.

- Branding and Packaging: Private labeling and customized packaging to enhance brand identity.

- Technical Support: Engineering assistance and training for proper scaffold assembly and use.

- Flexible Production: Ability to handle large-scale orders with consistent quality.

- Compliance Assurance: Ensuring products meet local and international safety standards.

Logistics and Packaging Solutions

Efficient logistics and packaging are critical for international distribution. Japanese suppliers provide:

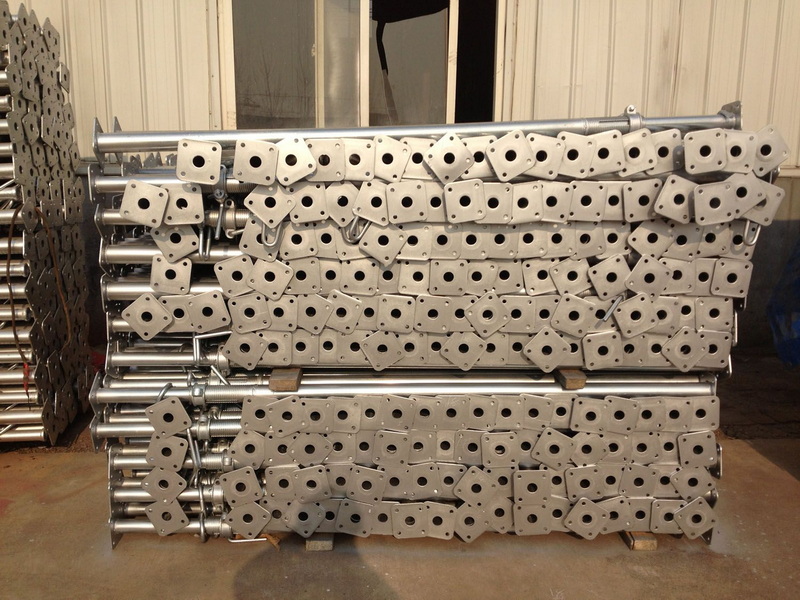

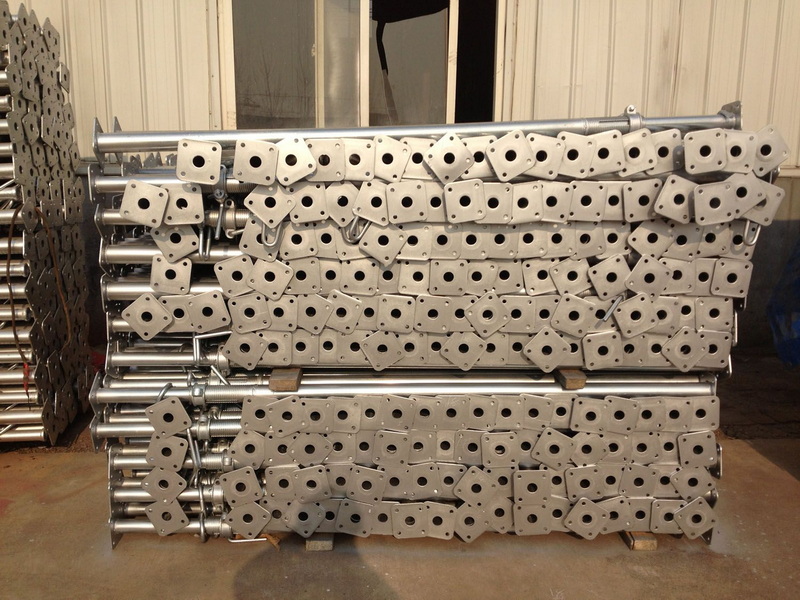

- Steel Pallets: Facilitate easy handling with forklifts, reducing loading/unloading times.

- Bulk Packaging: Maximizes container space for cost-effective shipping.

- Protective Wrapping: Prevents corrosion and damage during transit, especially for galvanized components.

- Custom Packaging: Tailored to client branding and shipping needs, enhancing market appeal.

These solutions ensure that frame scaffolding components arrive safely and ready for immediate use or resale.

Conclusion

Japan's shoring frame scaffolding manufacturers and suppliers combine decades of experience, advanced manufacturing technologies, and rigorous quality control to deliver high-performance scaffolding systems. Their products are characterized by durability, safety, modularity, and customization capabilities that meet the demanding needs of construction, industrial, and infrastructure projects worldwide. For foreign brands, wholesalers, and producers seeking reliable OEM partners, Japanese suppliers offer competitive pricing, technical expertise, and excellent after-sales support. Partnering with these manufacturers ensures access to premium frame scaffolding solutions that enhance project efficiency and safety.

FAQ

1. What materials are typically used in Japanese frame scaffolding?

Japanese frame scaffolding is primarily made from high-strength steel or lightweight aluminum, often treated with hot-dip galvanizing or powder coating to improve corrosion resistance and durability.

2. Are Japanese frame scaffolding manufacturers able to provide OEM services?

Yes, many Japanese manufacturers offer OEM services including customization of design, branding, packaging, and technical support tailored to foreign clients.

3. How does Japanese frame scaffolding ensure safety on construction sites?

Manufacturers comply with strict Japanese and international standards such as JIS and ISO, incorporating safety features like guardrails, locking pins, and anti-slip platforms, alongside rigorous quality control.

4. What advantages does modular frame scaffolding offer?

Modular frame scaffolding allows for quick assembly and disassembly, flexible configurations, adaptability to different project requirements, and improved safety and efficiency on site.

5. How do Japanese manufacturers maintain high product quality?

Through automated welding, CNC machining, laser cutting, stringent material testing, and adherence to ISO and JIS standards, Japanese manufacturers ensure consistent quality and durability.