Content Menu

● Introduction to Cuplock Scaffolding

>> Historical Background

>> Importance in Construction

● Key Features of Cuplock Scaffolding

>> Unique Cup-Node Connection

>> High Load-Bearing Capacity

>> Lightweight and Durable

>> Modular Design

>> Safety Features

● Advantages of Cuplock Scaffolding

>> Cost-Effective Solution

>> Versatility in Applications

>>> Residential Construction

>>> Commercial Projects

>>> Industrial Applications

>> Enhanced Safety Features

>>> Compliance with Safety Standards

>>> Reduced Risk of Falls

● Specifications of Cuplock Scaffolding

>> Detailed Component Breakdown

● Installation Process

>> Tips for Effective Installation

● Maintenance and Durability

>> Regular Inspections

>> Proper Storage Practices

● Environmental Considerations

>> Recyclable Materials

>> Reduced Material Waste

● Applications of Cuplock Scaffolding

>> Building Construction

>> Industrial Maintenance

>> Event Staging

>> Formwork Support

● Comparison with Other Scaffolding Systems

● Conclusion

● FAQ

>> 1. What materials are used in cuplock scaffolding?

>> 2. How does cuplock scaffolding improve safety?

>> 3. Can cuplock scaffolding be used on uneven ground?

>> 4. What is the maximum height for cuplock scaffolding?

>> 5. How does cuplock scaffolding compare with traditional systems?

● Citations:

Cuplock scaffolding has gained significant traction in the construction industry due to its innovative design and robust specifications. This article will delve into the numerous advantages of the cuplock scaffolding system, exploring its design features, specifications, and practical applications. We will also provide insights into its efficiency, safety, and versatility, making it a preferred choice for various construction projects.

Introduction to Cuplock Scaffolding

Cuplock scaffolding is a modular steel scaffolding system characterized by its unique cup-node connection mechanism. This system allows for quick assembly and disassembly, making it an efficient choice for various construction projects. The cuplock system is particularly known for its reliability, safety, and cost-effectiveness.

Historical Background

The cuplock scaffolding system was developed in the 1970s as a response to the growing need for safer and more efficient scaffolding solutions in construction. Over the years, it has gained popularity worldwide due to its ease of use and adaptability to different construction environments.

Importance in Construction

In an industry where safety and efficiency are paramount, cuplock scaffolding provides a solution that meets both criteria. Its design allows for rapid deployment on construction sites while ensuring that workers have a secure platform to operate from.

Key Features of Cuplock Scaffolding

Unique Cup-Node Connection

The defining feature of cuplock scaffolding is its circular cup-node connection, which allows multiple horizontal members to connect to vertical standards without the need for loose bolts or wedges. This design not only enhances safety but also speeds up the assembly process.

High Load-Bearing Capacity

Cuplock scaffolding is constructed from high-yield strength steel, ensuring that it can support significant loads while maintaining stability. The bottom cups are designed to distribute loads effectively, providing a strong shear-bearing capacity.

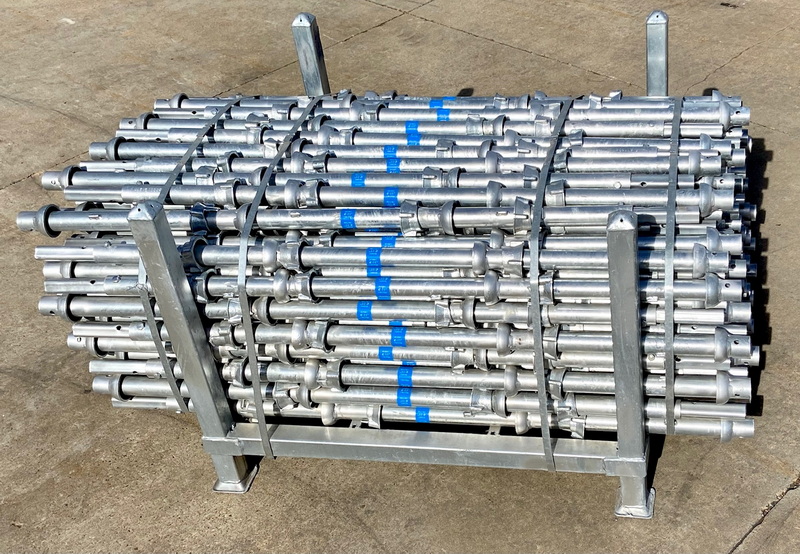

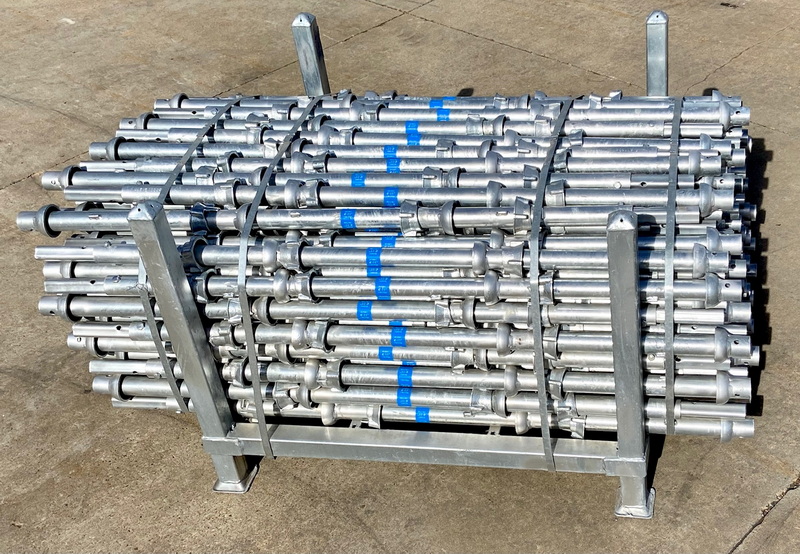

Lightweight and Durable

Despite its strength, cuplock scaffolding is lighter than traditional scaffolding systems, making it easier to handle and transport. The hot-dip galvanization process used in manufacturing extends the lifespan of the components, making them resistant to rust and wear.

Modular Design

The modular nature of cuplock scaffolding allows for easy customization based on project requirements. Components can be added or removed as needed, making it a flexible option for various job sites.

Safety Features

Cuplock scaffolding incorporates several safety features:

- Guardrails: Installed at various heights to prevent falls.

- Toe Boards: Prevent tools and materials from falling off the platform.

- Non-Slip Platforms: Ensure stable footing for workers.

Advantages of Cuplock Scaffolding

Cost-Effective Solution

The cuplock system significantly reduces labor costs due to its quick assembly and disassembly capabilities. Workers can complete installations 30% to 50% faster compared to traditional methods, translating into lower overall project costs.

Versatility in Applications

Cuplock scaffolding can be adapted for various construction needs, including single-row and double-row setups, cantilever scaffolds, and support frames. Its flexible design allows it to accommodate different load requirements and site conditions.

Residential Construction

In residential projects, cuplock scaffolding provides safe access for workers while allowing for easy adjustments as work progresses.

Commercial Projects

For commercial buildings, the ability to quickly set up and dismantle scaffolding can save time and money on large-scale projects.

Industrial Applications

In industrial settings such as factories and warehouses, cuplock scaffolding can support maintenance work at various heights safely.

Enhanced Safety Features

The cuplock system's design minimizes the risk of accidents during assembly and use. The self-locking mechanism ensures that components remain securely in place once installed, reducing the likelihood of structural failure.

Compliance with Safety Standards

Cuplock scaffolding complies with international safety standards, making it a reliable choice for contractors who prioritize worker safety.

Reduced Risk of Falls

With secure connections and stable platforms, workers are less likely to experience falls or accidents while using cuplock scaffolding.

Specifications of Cuplock Scaffolding

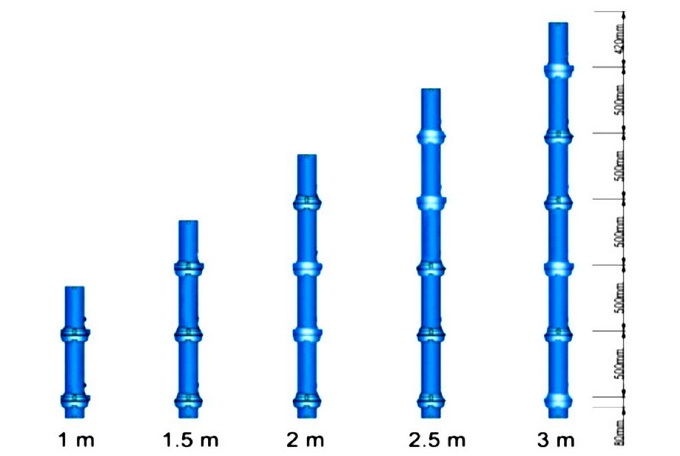

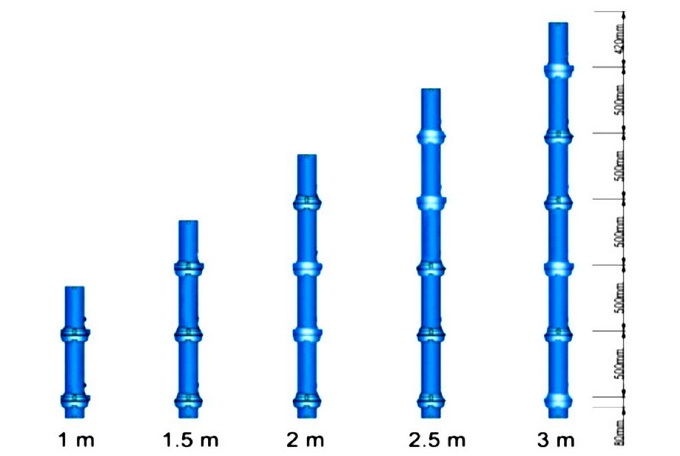

| Component | Specification |

| Standard Size | 0.5m to 4m |

| Material | S355 Steel |

| Tube Thickness | 3.2mm or 4mm |

| Load Capacity | Up to 199 kN |

| Finish | Hot-dip Galvanized |

Detailed Component Breakdown

- Standards: Vertical posts that provide structural support.

- Ledgers: Horizontal beams that connect between standards.

- Braces: Diagonal supports that enhance stability.

- Base Plates: Foundation elements that distribute weight evenly across surfaces.

Installation Process

The installation of cuplock scaffolding is straightforward:

1. Position Base Plates: Place base plates at required positions.

2. Install Standards: Set up cuplock standards on each base plate.

3. Attach Ledgers: Fix ledgers between standards.

4. Level Measurements: Use spirit levels to ensure horizontal alignment.

5. Secure with Top Cups: Lock ledgers in place using top cups.

Tips for Effective Installation

- Always ensure that ground conditions are stable before beginning installation.

- Use protective gear during assembly to enhance worker safety.

- Regularly check connections during installation to ensure they are secure.

Maintenance and Durability

Cuplock scaffolding requires minimal maintenance due to its robust design and materials used in construction:

Regular Inspections

Conduct regular inspections to check for any signs of wear or damage:

- Look for rust or corrosion on steel components.

- Check connections for tightness.

- Ensure that all components are free from debris or obstructions.

Proper Storage Practices

When not in use, store cuplock components in a dry area to prevent moisture accumulation:

- Stack components neatly to avoid bending or damage.

- Cover with tarps if stored outdoors to protect against weather conditions.

Environmental Considerations

As sustainability becomes increasingly important in construction practices, cuplock scaffolding offers several environmental benefits:

Recyclable Materials

The steel used in cuplock systems is fully recyclable at the end of its life cycle, reducing waste in landfills.

Reduced Material Waste

Due to its modular nature, less material is wasted during installation compared to traditional systems that may require more cutting or adjustments on-site.

Applications of Cuplock Scaffolding

Cuplock scaffolding's versatility makes it suitable for a wide range of applications:

Building Construction

Used extensively for both interior and exterior work such as bricklaying, painting, and renovation projects.

Industrial Maintenance

Ideal for maintenance tasks in power plants, refineries, and chemical plants where access at height is required safely.

Event Staging

Provides reliable structures for staging events, including concerts and public gatherings where elevated platforms are necessary.

Formwork Support

Acts as a stable support system for concrete formwork during pouring processes.

Comparison with Other Scaffolding Systems

When comparing cuplock scaffolding with other systems like ringlock or tube-and-clamp systems, several factors come into play:

| Feature | Cuplock Scaffolding | Ringlock Scaffolding | Tube-and-Clamp Scaffolding |

| Assembly Speed | Fast | Moderate | Slow |

| Weight | Lightweight | Moderate | Heavy |

| Load Capacity | High | Moderate | Variable |

| Safety | High | Moderate | Variable |

| Cost Effectiveness | High | Moderate | Low |

Conclusion

The cuplock scaffolding system stands out as a superior choice for construction projects due to its innovative design, cost-effectiveness, versatility, and safety features. As industries continue to seek efficient solutions for their scaffolding needs, cuplock systems will likely remain at the forefront of modern construction practices.

FAQ

1. What materials are used in cuplock scaffolding?

Cuplock scaffolding is primarily made from S355 steel with a thickness of either 3.2mm or 4mm, providing both strength and durability.

2. How does cuplock scaffolding improve safety?

The unique cup-node connection eliminates loose components that could fall during assembly or use while the self-locking mechanism ensures stability under load.

3. Can cuplock scaffolding be used on uneven ground?

Yes! Cuplock scaffolding is designed to adapt to various ground conditions, making it suitable for sites with height differences.

4. What is the maximum height for cuplock scaffolding?

Single-row scaffolds can reach heights of up to 24 meters while double-row configurations can go up to 50 meters depending on specific load requirements.

5. How does cuplock scaffolding compare with traditional systems?

Cuplock scaffolding offers faster assembly times (30%-50% quicker), reduced labor costs, enhanced safety features compared to traditional tube-and-clamp systems.

Citations:

[1] https://rapid-scafform.com/cuplock-scaffold/

[2] https://primesteeltech.co.in/what-is-cuplock-scaffolding.html

[3] https://www.internationalscaffolding.com/projects/what-is-a-cuplock-scaffolding-system/

[4] https://primesteeltech.co.in/cuplock-scaffolding-systems-benefits-components-applications-explained.html

[5] https://www.huennebeck.com/uploads/files/cuplok_system_scaffold_user_guide_en_2015-05-29.pdf

[6] https://apacsafety.com/difference-between-cuplock-and-ringlock-scaffolding/

[7] https://www.adtoscaffold.com/new/advantages_of_cuplock_scaffolding.html

[8] https://aaitscaffold.com/cuplock-scaffolding/everything-about-cuplock-scaffolding-system/

[9] https://aaitscaffold.com/blog/cuplock-scaffolding-types-uses-benefits-and-safety/