Content Menu

● Introduction to Aluminum Plank Grating

● Applications of Aluminum Plank Grating

>> 1. Industrial Flooring

>> 2. Architectural Features

>> 3. Wastewater Treatment Facilities

>> 4. Marine Applications

>> 5. Food Processing Plants

>> 6. Pedestrian Walkways and Bridges

>> 7. Theme Parks and Amusement Areas

>> 8. Stadiums and Sports Facilities

● Advantages of Aluminum Plank Grating

>> 1. Lightweight and Easy to Install

>> 2. Corrosion Resistance

>> 3. Aesthetic Appeal

>> 4. Low Maintenance Requirements

>> 5. Environmental Sustainability

>> 6. Cost-Effectiveness

● Installation and Maintenance Tips

>> Installation

>> Maintenance

● Safety Considerations

● Innovative Applications

● Conclusion

● FAQ

>> 1. What is aluminum plank grating?

>> 2. How does aluminum plank grating compare to steel?

>> 3. Can aluminum plank grating be customized?

>> 4. Is aluminum plank grating suitable for outdoor use?

>> 5. What industries commonly use aluminum plank grating?

● Citations:

Aluminum plank grating is a versatile and durable material widely used across various industries due to its unique properties. This article explores the common uses of aluminum plank grating, highlighting its applications, advantages, and specific features that make it an ideal choice for many projects.

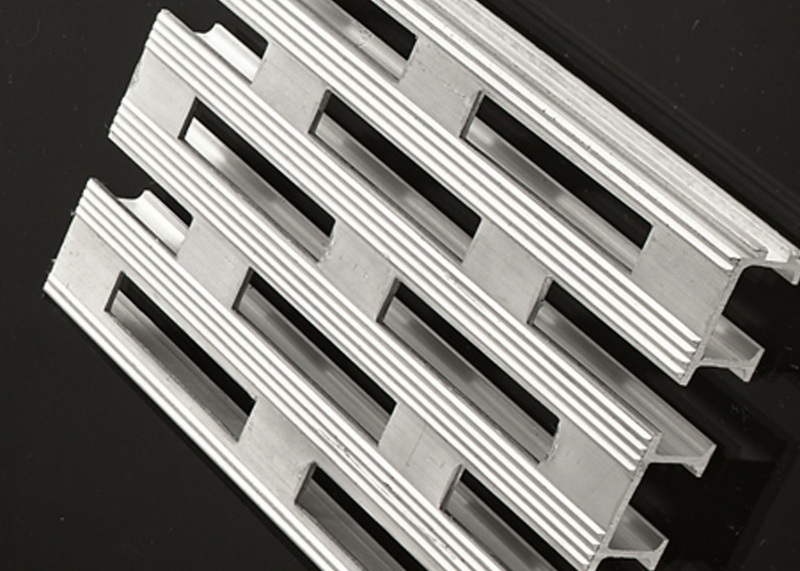

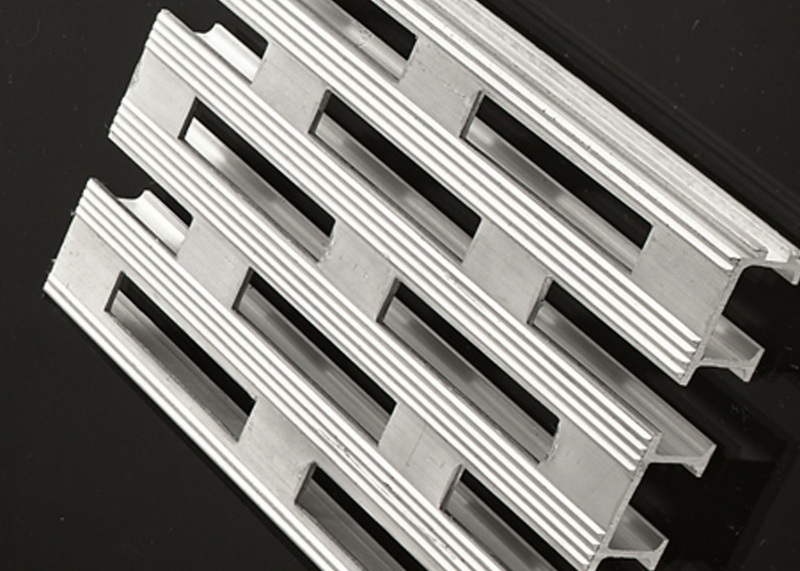

Introduction to Aluminum Plank Grating

Aluminum plank grating is constructed from aluminum extrusions that provide a lightweight yet strong solution for flooring and other structural needs. Its design allows for efficient drainage and ventilation while maintaining load-bearing capabilities. The use of aluminum as a primary material offers several benefits, including resistance to corrosion, ease of installation, and aesthetic appeal.

Applications of Aluminum Plank Grating

Aluminum plank grating is utilized in various sectors due to its adaptability. Here are some common applications:

1. Industrial Flooring

Aluminum plank grating is often used in industrial settings where heavy machinery operates. Its strength-to-weight ratio makes it suitable for:

- Catwalks: Providing safe access to elevated areas.

- Platforms: Supporting equipment and personnel.

- Loading Ramps: Facilitating the movement of goods.

2. Architectural Features

In architectural applications, aluminum plank grating enhances both functionality and aesthetics. Common uses include:

- Sunshades: Reducing heat gain in buildings.

- Railings: Offering safety without obstructing views.

- Fountains: Adding decorative elements to landscapes.

3. Wastewater Treatment Facilities

Due to its corrosion resistance, aluminum plank grating is ideal for environments exposed to harsh chemicals and moisture. Applications include:

- Walkways: Allowing personnel safe passage over treatment areas.

- Platform Supports: Elevating equipment above potentially hazardous substances.

4. Marine Applications

Aluminum's lightweight nature and resistance to saltwater make it suitable for marine environments. Uses include:

- Ship Decks: Providing safe walking surfaces on vessels.

- Barge Walkways: Ensuring stability during loading operations.

5. Food Processing Plants

In food processing, hygiene is crucial. Aluminum plank grating meets these needs by being non-toxic and easy to clean. Applications include:

- Preparation Areas: Allowing for quick drainage and cleaning.

- Storage Platforms: Supporting food products while maintaining sanitation standards.

6. Pedestrian Walkways and Bridges

Aluminum plank grating is also used in public spaces for pedestrian walkways and bridges due to its durability and aesthetic appeal. It provides a safe and visually appealing path for pedestrians.

7. Theme Parks and Amusement Areas

In theme parks and amusement areas, aluminum plank grating is used for attractions and walkways. Its corrosion resistance and ease of maintenance make it suitable for environments with high humidity or exposure to water.

8. Stadiums and Sports Facilities

Aluminum plank grating is used in stadiums for seating areas, walkways, and platforms. Its lightweight nature and strength ensure safety while minimizing structural weight.

Advantages of Aluminum Plank Grating

The benefits of using aluminum plank grating extend beyond its applications:

1. Lightweight and Easy to Install

Aluminum is significantly lighter than steel, making it easier to handle and install. This characteristic reduces labor costs and installation time.

2. Corrosion Resistance

Aluminum naturally forms a protective oxide layer that prevents rusting, making it ideal for outdoor or humid environments.

3. Aesthetic Appeal

The smooth finish of aluminum plank grating can enhance the visual appeal of structures, making it suitable for both functional and decorative purposes.

4. Low Maintenance Requirements

Unlike other materials that may require regular painting or treatment, aluminum grating is virtually maintenance-free, saving time and resources in the long run.

5. Environmental Sustainability

Aluminum is highly recyclable, which makes aluminum plank grating an environmentally friendly choice for construction projects.

6. Cost-Effectiveness

While the initial cost of aluminum plank grating might be higher than some alternatives, its long lifespan and minimal maintenance needs make it cost-effective over time.

Installation and Maintenance Tips

Installation

- Preparation: Ensure the surface is level and clean before installation.

- Fastening: Use appropriate fasteners to secure the grating in place.

- Alignment: Align the grating panels carefully to ensure even spacing and support.

Maintenance

- Cleaning: Regularly clean the grating with mild detergents to prevent dirt buildup.

- Inspection: Periodically inspect for signs of wear or damage.

- Repair: Address any damage promptly to maintain structural integrity.

Safety Considerations

When using aluminum plank grating, safety is paramount:

- Slip Resistance: Apply slip-resistant coatings or surfaces to prevent accidents.

- Load Capacity: Ensure the grating is designed to handle the intended load.

- Edge Protection: Install edge guards to prevent falls from elevated areas.

Innovative Applications

As technology advances, aluminum plank grating is being integrated into innovative projects:

- Green Roofs: Used in green roof designs to support vegetation while providing structural support.

- Solar Panel Mounts: Employed as a mounting system for solar panels due to its lightweight and durable nature.

Conclusion

Aluminum plank grating serves a multitude of purposes across various industries due to its strength, lightweight nature, and resistance to corrosion. Its versatility allows it to be used in industrial settings, architectural designs, marine applications, wastewater treatment facilities, food processing plants, and more. As industries continue to seek durable and efficient materials, aluminum plank grating will remain a preferred choice.

FAQ

1. What is aluminum plank grating?

Aluminum plank grating is a type of flooring made from aluminum extrusions designed for strength and durability while allowing air and light passage.

2. How does aluminum plank grating compare to steel?

Aluminum is lighter than steel, resistant to corrosion, and requires less maintenance than steel options.

3. Can aluminum plank grating be customized?

Yes, manufacturers can customize aluminum plank grating in terms of size, shape, and finish based on specific project requirements.

4. Is aluminum plank grating suitable for outdoor use?

Absolutely! Its corrosion resistance makes it ideal for outdoor applications exposed to weather elements.

5. What industries commonly use aluminum plank grating?

Common industries include construction, food processing, wastewater treatment, marine services, architectural design, and more.

Citations:

[1] https://interstategratings.com/why-choose-aluminum-grating/

[2] https://ikg.com/stock-panels/aluminum-plank/

[3] https://www.mcnichols.com/plank-grating/plank

[4] https://www.mcnichols.com/blog/what-are-aluminum-grates

[5] https://ikg.com/faqs/

[6] https://www.brown-campbell.com/products/info?page=other-products&cmsID=aluminum-plank

[7] https://www.mcnichols.com/blog/how-to-choose-the-right-grating-for-your-application

[8] https://www.metals4uonline.com/aluminum-plank-grating-12ga-x-4-3-4-wide-x-2-tall/

[9] https://gratingpacific.com/product/aluminum-plank-grating/

[10] https://www.prmetals.com/traction-tread-plank-grating-2-high-x-12-wide-x-0.125-thick-tt-1220.125-a-a/p/575/

[11] https://unistrutstore.com/125-aluminum-perfogrip-safety-grating-plank.html

[12] https://www.ohiogratings.com/grating-types/plank-grating-standard-series/

[13] https://www.youtube.com/watch?v=0OY4KEehWN0

[14] https://gratingpacific.com/product/aluminum-plank-grating-details/

[15] https://www.youtube.com/watch?v=cEO_j9S0SS8

[16] https://www.eng-tips.com/threads/aluminum-grating-with-steel-beams.6506/

[17] https://interstategratings.com/grating-101/

[18] https://www.mcnichols.com/plank-grating

[19] https://www.youtube.com/watch?v=6zDnHNCJQo8

[20] https://gratingpacific.com/wp-content/uploads/2020/10/LOAD-TABLE-ALUMINUM-PLANK-GRATING-GP.pdf