Content Menu

● Introduction to Cuplock Scaffolding

● Key Components of Cuplock Scaffolding

● Standard Material for Cuplock Scaffolding

● Importance of Material Quality

● Identifying Cuplock Scaffolding Parts Names

● Additional Components and Accessories

● Conclusion

● FAQ

>> 1. What are the main components of a cuplock scaffolding system?

>> 2. What is the purpose of ledger braces in cuplock scaffolding?

>> 3. What are the benefits of using cuplock scaffolding?

>> 4. What materials are typically used for cuplock scaffolding parts?

>> 5. How does the cuplock locking mechanism work?

● Citations:

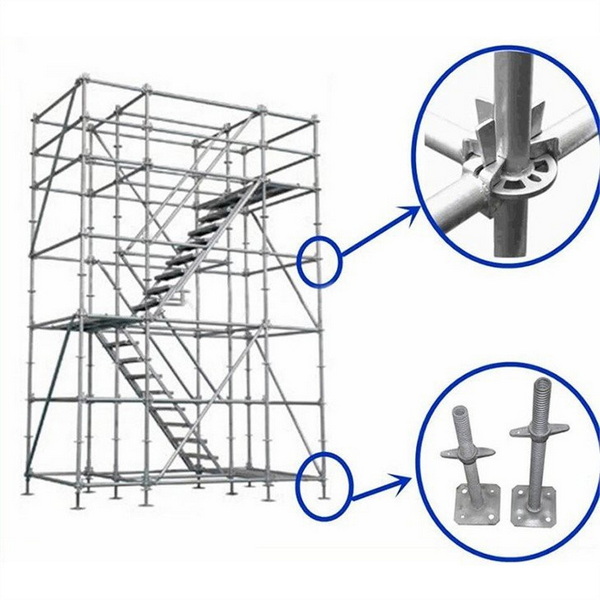

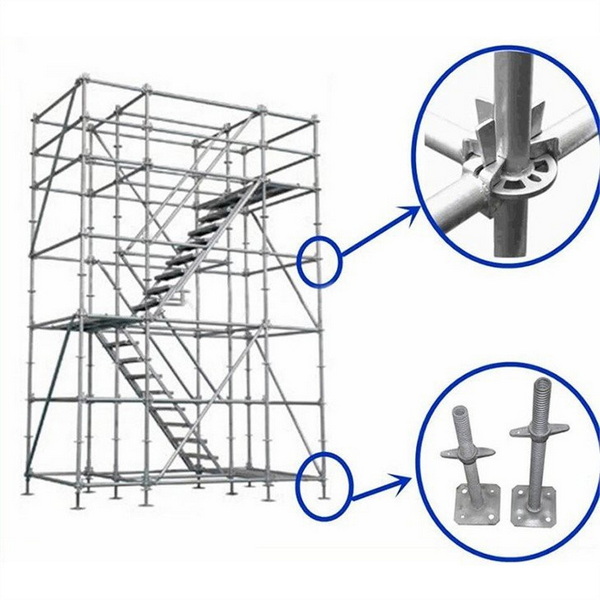

Cuplock scaffolding is a modular scaffolding system widely used in construction for its efficiency and safety. It consists of several key components that work together to provide a stable and secure platform for workers and materials. Understanding the different cuplock scaffolding parts names is essential for effective assembly and maintenance of the structure.

Introduction to Cuplock Scaffolding

Cuplock scaffolding is characterized by its unique locking mechanism, which allows for quick and secure assembly without the need for nuts and bolts. The system includes vertical standards with cups welded at regular intervals and horizontal ledgers that connect to these cups. This modular design makes it easy to set up and dismantle scaffolding structures, saving time and labor costs.

Key Components of Cuplock Scaffolding

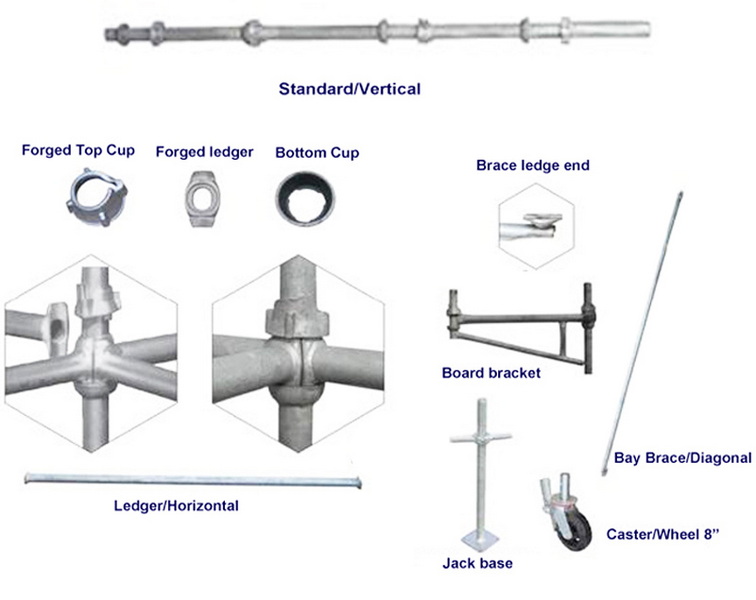

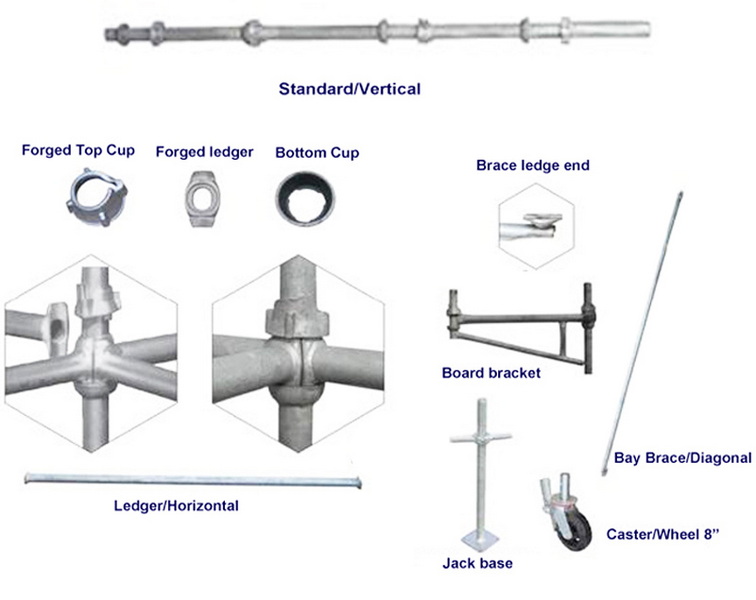

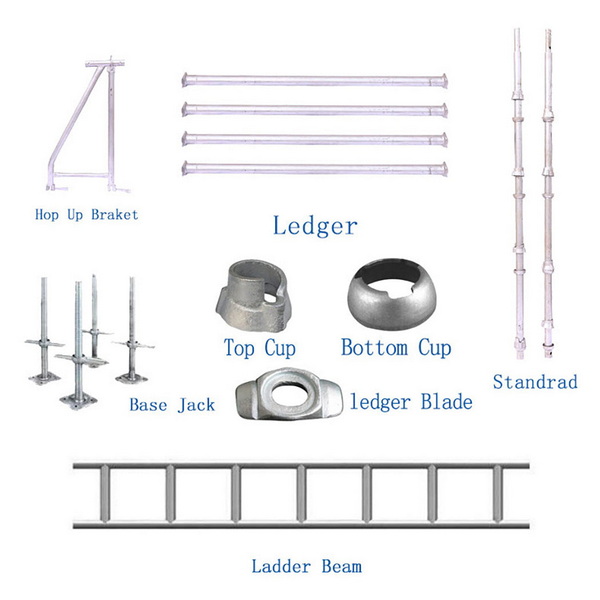

1. Vertical Standards (Cuplock Standards): These are the vertical parts of the scaffolding system, made from high-strength steel tubes with a diameter of 48.3 mm and a thickness of 3.2 mm or 4.0 mm. The standards are available in various lengths to accommodate different project requirements.

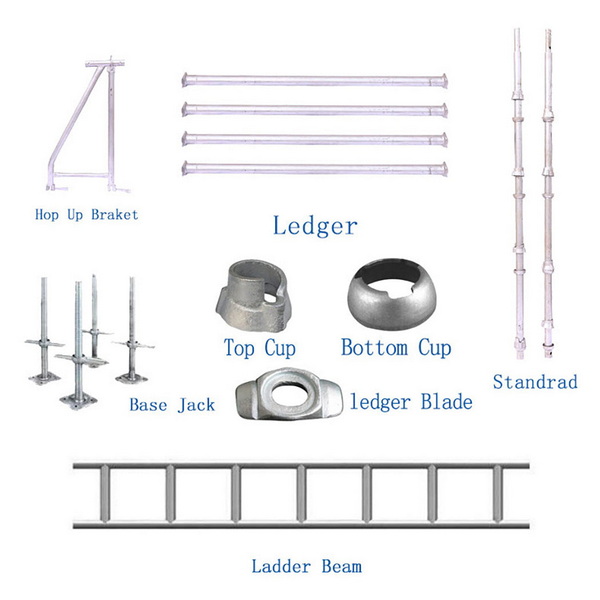

2. Ledgers: These are horizontal tubes that connect to the vertical standards using the cuplock mechanism. Ledgers provide the main horizontal support and are crucial for maintaining the structural integrity of the scaffolding.

3. Ledger Braces: These are horizontal and diagonal bracing components that provide additional stability and support to the ledgers, ensuring the scaffolding system is strong and stable.

4. Node Cups (Top Cups and Bottom Bowls): These are cylindrical cups welded to the standards at regular intervals. The top cup holds the next level of ledgers and boards, while the bottom bowl catches the ledger and brace.

5. Joint Pins: These connect the ledger, brace, and ledgers, ensuring stability and strength support.

6. Scaffold Boards (Planks): These are horizontal members that provide a working platform for workers. They are made of wood or aluminum.

7. Braces (Diagonal Braces): These are inclined tubes positioned diagonally to provide additional support and stability to the structure, preventing lateral movement.

8. Base and Head Plates: These are used to stabilize the base and top of the scaffolding structure. Base plates distribute the weight evenly on the ground, while head plates secure the top of the scaffolding.

Standard Material for Cuplock Scaffolding

The standard material for cuplock scaffolding parts is high-strength steel, typically S355 or Q345, which offers a yield strength of more than 235 N/mm². The tubes are usually hot-dip galvanized to provide a durable and corrosion-resistant finish.

Importance of Material Quality

Using high-quality materials ensures that the scaffolding can support heavy loads safely and withstand harsh environmental conditions. The galvanized finish not only protects the steel from corrosion but also enhances the aesthetic appeal of the scaffolding structure.

Identifying Cuplock Scaffolding Parts Names

To identify cuplock scaffolding parts names, consider the following components:

1. Cuplock Standards: These are the vertical pipes that form the framework of the scaffolding.

2. Ledgers: Horizontal tubes that connect to the standards and provide support for the scaffold platform.

3. Braces: These provide additional stability to the structure and are typically made from steel.

4. Node Cups: These include top cups and bottom bowls that secure the ledgers and provide stability support.

5. Scaffold Boards: These are the horizontal members that provide a working platform for workers.

Additional Components and Accessories

- Adjustable Leveling Jacks: These are used to level the scaffolding structure on uneven ground.

- Hop-Up Brackets: These are used to create a platform on a scaffolding system, providing a safe and stable working surface at various heights.

- Cuplock Cantilever Frames: These are scaffolding frames designed to create cantilevered platforms or walkways.

Conclusion

Understanding the different cuplock scaffolding parts names is crucial for effective assembly, maintenance, and safety of the structure. By recognizing components like standards, ledgers, braces, and node cups, you can ensure that your scaffolding system is properly set up and secure. Always opt for components from reputable manufacturers that adhere to international quality standards.

FAQ

1. What are the main components of a cuplock scaffolding system?

The main components include vertical standards, ledgers, node cups (top cups and bottom bowls), joint pins, scaffold boards, and braces.

2. What is the purpose of ledger braces in cuplock scaffolding?

Ledger braces provide additional stability and support to the ledgers, ensuring the scaffolding system is strong and stable.

3. What are the benefits of using cuplock scaffolding?

Cuplock scaffolding offers benefits such as speed and efficiency in assembly, enhanced safety and stability, and cost-effectiveness due to its modular design.

4. What materials are typically used for cuplock scaffolding parts?

Cuplock scaffolding parts are typically made from high-strength steel, such as S355 or Q345, and are often hot-dip galvanized for corrosion resistance.

5. How does the cuplock locking mechanism work?

The cuplock mechanism involves fixed lower cups and movable top cups that rotate to lock onto horizontal ledgers and transoms, allowing for quick and secure assembly.

Citations:

[1] https://www.alibaba.com/showroom/cuplock-scaffolding-parts-name.html

[2] https://www.youtube.com/watch?v=ojYR6MRAoEI

[3] https://www.youtube.com/watch?v=zU9g34ycO8k

[4] https://www.sparsteel.com/blog/cuplock-scaffolding-types-uses-and-benefits/

[5] https://www.youtube.com/watch?v=2FbwLFj1aFY

[6] https://www.youtube.com/watch?v=0heLcSGp4cI

[7] https://primesteeltech.co.in/cuplock-scaffolding-systems-benefits-components-applications-explained.html

[8] https://www.youtube.com/watch?v=dDmO_ocTcDg

[9] https://www.defenal.com/pdf/cuplock-scaffolding.pdf