Content Menu

● Introduction to Scaffolding Clamps

● Importance of Scaffolding Clamps

● Types of Scaffolding Clamps

>> 1. Swivel Couplers

>> 2. Right-Angle Couplers

>> 3. Sleeve Couplers

>> 4. Putlog Couplers

>> 5. Beam Clamps

>> 6. Board Retaining Couplers (BRC)

>> 7. Limpet Clamps

>> 8. Adjustable Scaffolding Clamps

>> 9. Socket Scaffolding Clamps

● Applications of Scaffolding Clamps

● Safety Considerations for Scaffolding Clamps

● Materials Used for Scaffolding Clamps

● Tube and Clamp Scaffolding Systems

● Regulations and Standards

● Training and Competency

● Conclusion

● FAQ

>> 1. What are the main types of scaffolding clamps?

>> 2. Why are regular inspections important for scaffolding clamps?

>> 3. What materials are commonly used for scaffolding clamps?

>> 4. How do swivel couplers contribute to scaffolding flexibility?

>> 5. What is the role of board retaining couplers in scaffolding?

● Citations:

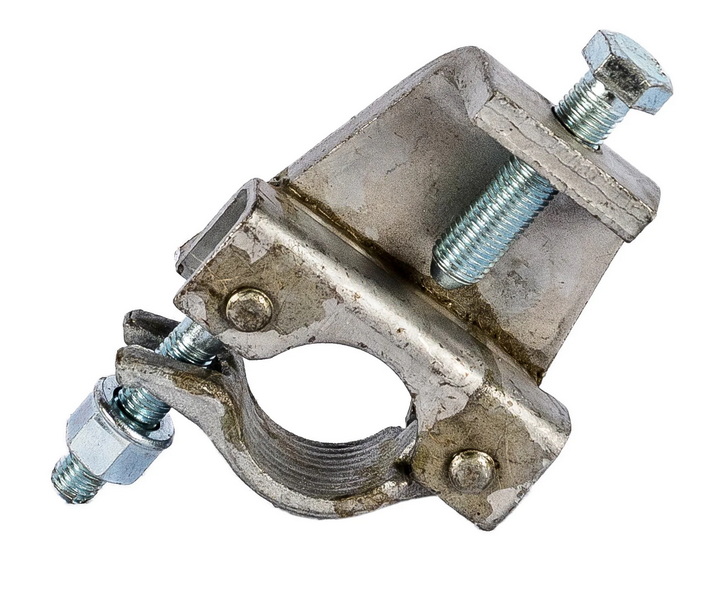

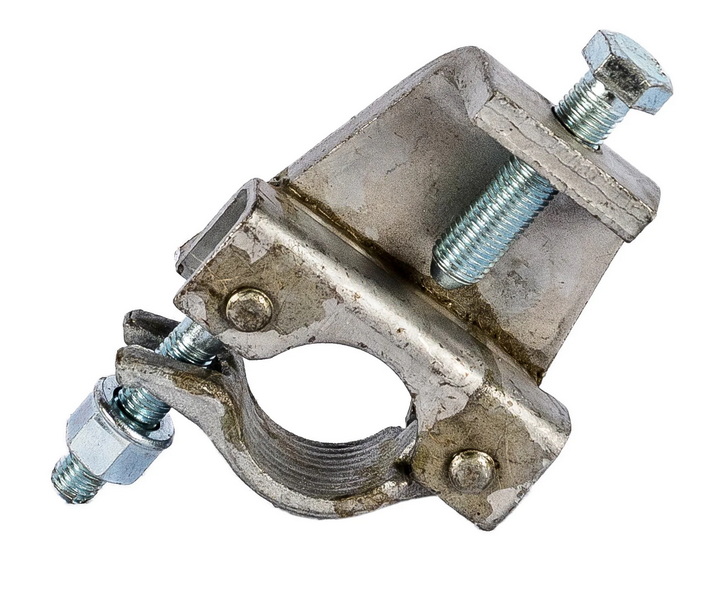

Scaffolding clamps, also known as scaffolding couplers, are essential components in the construction industry, used to connect and secure scaffolding tubes together. These clamps provide stability and strength to the scaffolding structure, ensuring a safe working environment for workers at height. In this article, we will explore the various types of scaffolding clamps, their applications, and importance in scaffolding systems.

Introduction to Scaffolding Clamps

Scaffolding clamps are designed to join scaffolding tubes, forming a robust framework that supports workers and materials during construction, maintenance, or repair projects. The versatility of these clamps allows for the creation of complex scaffolding configurations, making them indispensable in the industry.

Importance of Scaffolding Clamps

- Stability and Safety: Scaffolding clamps ensure that the scaffolding structure remains stable and secure, reducing the risk of accidents.

- Versatility: They allow for various configurations, making them suitable for different types of projects.

- Durability: Clamps are designed to withstand heavy loads and harsh environmental conditions.

Types of Scaffolding Clamps

There are several types of scaffolding clamps, each serving a specific purpose:

1. Swivel Couplers

Swivel couplers, or swivel clamps, are versatile connectors that allow the connection of scaffold tubes at any angle. They feature a ball joint that enables 360-degree rotation, making them ideal for complex scaffolding configurations.

2. Right-Angle Couplers

Right-angle couplers, or double couplers, connect two tubes at a 90-degree angle. They are commonly used in standard scaffolding configurations where stability and strength are crucial.

3. Sleeve Couplers

Sleeve couplers, or internal couplers, are used to extend the length of scaffolding tubes by connecting them end-to-end. They slide over the tubes and are secured with bolts or pins.

4. Putlog Couplers

Putlog couplers, or single couplers, are used to attach transoms or putlogs to ledger tubes. They provide stability and support in scaffolding configurations where a platform is constructed on one side of a structure.

5. Beam Clamps

Beam clamps are used to connect scaffolding tubes to beams or girders, providing additional support and stability to the structure.

6. Board Retaining Couplers (BRC)

BRC couplers are designed to secure scaffold boards in place, ensuring a safe working platform for workers.

7. Limpet Clamps

Limpet clamps are used to attach scaffolding to existing structures like columns or walls, providing additional support.

8. Adjustable Scaffolding Clamps

Adjustable scaffolding clamps are used when the scaffolding tubes are at different angles. This clamp can easily be adjusted to suit various angles, making it a popular choice in construction and other industries.

9. Socket Scaffolding Clamps

Socket clamps are popular for their excellent load-bearing capacity. They come with a female socket welded to the end of the tube, allowing the male end of the next tube to slide inside.

Applications of Scaffolding Clamps

Scaffolding clamps are used in various industries and projects:

- Construction Sites: For building, renovation, and maintenance projects.

- Industrial Settings: In refineries, petrochemical plants, and power plants.

- Temporary Structures: For building ramps, sheds, and stands.

Safety Considerations for Scaffolding Clamps

Safety is paramount when using scaffolding clamps:

- Proper Installation: Ensure all clamps are securely tightened and properly aligned.

- Regular Inspections: Check for signs of wear or damage.

- Training: Provide comprehensive training to workers on the safe use of scaffolding clamps.

Materials Used for Scaffolding Clamps

Scaffolding clamps are typically made from durable materials:

- Steel: Strong and durable, suitable for heavy-duty applications.

- Aluminum: Lightweight and corrosion-resistant, ideal for lighter scaffolding systems.

- Copper and Brass: Less common, used for specialized applications.

Tube and Clamp Scaffolding Systems

Tube and clamp scaffolding systems utilize a combination of steel tubes and specialized clamps to create a secure framework. These systems are versatile and adaptable to various configurations, making them suitable for complex or irregular structures.

Regulations and Standards

Compliance with local, state, and federal regulations is essential. This includes adhering to OSHA guidelines and relevant industry standards such as CSA standards for fall protection equipment.

Training and Competency

Ensuring that workers are properly trained and competent in the assembly and use of scaffolding clamps is crucial. Training should cover:

- Erection and Dismantling

- Fall Protection

- Use of PPE

- Use of Tools and Equipment

Conclusion

Scaffolding clamps are crucial components in the construction industry, providing the necessary stability and strength to scaffolding structures. By understanding the different types of scaffolding clamps and their applications, you can ensure safe and efficient scaffolding assembly.

FAQ

1. What are the main types of scaffolding clamps?

The main types of scaffolding clamps include swivel couplers, right-angle couplers, sleeve couplers, putlog couplers, beam clamps, and board retaining couplers.

2. Why are regular inspections important for scaffolding clamps?

Regular inspections are crucial to identify any signs of wear or damage, ensuring the scaffolding remains safe for use.

3. What materials are commonly used for scaffolding clamps?

Scaffolding clamps are typically made from steel, aluminum, copper, and brass, with steel being the most common due to its strength.

4. How do swivel couplers contribute to scaffolding flexibility?

Swivel couplers allow for connections at any angle, providing flexibility in scaffolding configurations and making them ideal for complex projects.

5. What is the role of board retaining couplers in scaffolding?

Board retaining couplers secure scaffold boards in place, ensuring a safe working platform for workers.

Citations:

[1] https://www.wm-scaffold.com/scaffolding-coupler.html

[2] https://www.youtube.com/watch?v=bmV1SlcXqG8

[3] https://firstoakcapital.co.uk/knowledge/what-is-tube-and-clamp-scaffolding/

[4] https://www.alibaba.com/showroom/types-of-scaffolding-clamps.html

[5] https://www.istockphoto.com/photos/scaffold-clamps

[6] https://www.grinsulating.com/top-benefits-tube-and-clamp-scaffold/

[7] https://grsscaffolding.com/blog/scaffolding-couplers-types/

[8] https://www.istockphoto.com/photos/scaffolding-clamps

[9] https://dss.net/scaffold-industrial-applications/

[10] https://www.gd-scaffold.com/news/types-of-couplers-in-scaffolding.html

[11] https://www.youtube.com/watch?v=ZWbx-Hmejog