Content Menu

● Understanding the Unique Challenges of High-Rise Scaffolding

● Types of Scaffolding Systems for High-Rise Buildings

>> 1. Supported Scaffolding

>> 2. Suspended Scaffolding

>> 3. Multi-Tiered Frame Scaffolding System

● Safety Considerations for High-Rise Scaffolding

● The Evolving Role of Technology in Scaffolding

● Conclusion

● FAQ

>> 1. What is the most significant safety risk associated with scaffolding in high-rise construction?

>> 2. How often should scaffolding be inspected on a high-rise construction site?

>> 3. What type of training should workers receive before working on high-rise scaffolding?

>> 4. How can technology improve scaffolding safety and efficiency in high-rise construction?

>> 5. What are the key considerations when designing a scaffolding system for a high-rise building?

● Citations:

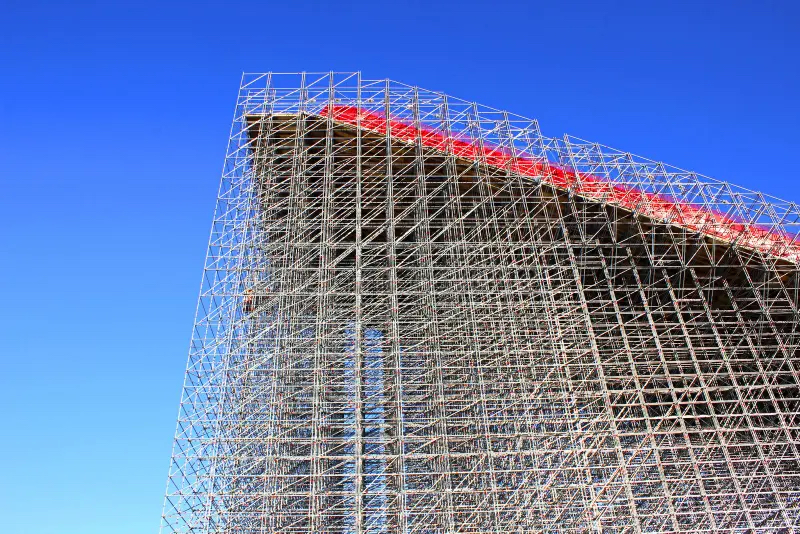

Scaffolding systems are indispensable for the construction, maintenance, and repair of high-rise buildings[1][7]. They provide safe and stable platforms for workers and materials at elevated heights. Selecting the appropriate scaffolding system for a high-rise project is crucial, as it directly impacts safety, efficiency, and cost-effectiveness[1][4]. This article explores the various types of scaffolding systems commonly used in high-rise construction, highlighting their features, benefits, and applications.

Understanding the Unique Challenges of High-Rise Scaffolding

High-rise construction presents unique challenges that demand specialized scaffolding solutions[5]. These challenges include:

- Height and Accessibility: Providing access to extreme heights requires robust and stable scaffolding systems[1].

- Wind and Weather Conditions: High-rise scaffolding must withstand strong winds and adverse weather conditions[3].

- Limited Space: Construction sites in urban areas often have limited space for scaffolding installation and material handling[1].

- Safety Concerns: Ensuring worker safety at elevated heights is paramount[4].

- Efficient Material Handling: Moving materials vertically and horizontally on high-rise scaffolding requires careful planning and execution[1].

- Access and Egress: Safe and efficient access to and from the scaffolding platforms is crucial[5].

Types of Scaffolding Systems for High-Rise Buildings

Several types of scaffolding systems are commonly used in high-rise construction, each with its own advantages and limitations[3].

1. Supported Scaffolding

Supported scaffolding systems are erected from the ground up, relying on vertical supports (standards) that rest on a solid base[3]. They are commonly used in the initial construction phases of high-rise buildings, providing a sturdy framework for accessing lower to mid-level elevations[3].

- Tube and Clamp Scaffolding: This traditional system offers versatility and customization, allowing it to fit the complex shapes and contours often found in high-rise architecture[3]. It is adaptable for navigating challenging access points and accommodating unique structural designs[3].

- Modular Systems (e.g., Ringlock): These systems offer rapid assembly, high load-bearing capacity, and exceptional stability, making them well-suited for high-rise construction where efficiency and safety are paramount[3]. Ringlock, in particular, has gained popularity due to its user-friendly design and robust construction[3]. Modular scaffolding systems provide enhanced stability with their prefabricated components and adjustable features, allowing for secure and adaptable structures[5].

2. Suspended Scaffolding

Suspended scaffolding systems are suspended from the building's rooftop or upper floors, providing unparalleled access to vertical surfaces[3]. They are particularly useful for facade work, window replacement, window cleaning, and maintenance on high-rise buildings[3].

- Two-Point Suspension: Commonly known as swing stages, these platforms are suspended by ropes or cables from two points, allowing for lateral movement along the building facade[3].

- Multi-Point Suspension: For larger platforms or more complex tasks, multi-point suspension systems offer greater stability and load-bearing capacity[3].

3. Multi-Tiered Frame Scaffolding System

For large-scale high-rise construction projects, a multi-tiered frame scaffolding system is often selected to provide access to workers on every floor of the building[1]. The system comprises several stacked frames with multiple horizontal platforms, each providing a safe and stable working area for workers[1].

- Modular Design: The scaffold is built using modular components that can be easily adjusted and adapted to the changing height of the building as construction progresses[1].

- Vertical and Horizontal Access: Each tier of the scaffolding provides workers with the necessary access to the building's structure, while horizontal platforms allow workers to move easily from one side of the building to another[1].

- Safety Railings and Guardrails: Guardrails are installed on all open sides of the scaffolding platforms, with additional safety features like toe boards to prevent tools and materials from falling[1][2].

Safety Considerations for High-Rise Scaffolding

Safety is paramount when working with scaffolding on high-rise buildings[4]. The following safety measures should be implemented:

- Fall Protection: Use personal fall arrest systems (PFAS) such as harnesses and lanyards[2][4]. Ensure guardrails, mid-rails, and toeboards are in place on all open sides[2][1]. Safety nets may be used in conjunction with other fall protection measures to provide an additional layer of security[3][4].

- Load-Bearing Capacity: Ensure the scaffolding can support the intended load, including workers, materials, and equipment[4].

- Proper Anchoring: Securely anchor scaffolding to the building's structure to prevent shifting or collapse[5]. Use base plates, tie-ins, and bracing systems designed for high-rise applications[5].

- Regular Inspections: Frequent inspections and maintenance of scaffolding are essential to detect any signs of wear or instability[5]. Implementing real-time monitoring systems can help track structural integrity[5].

- Wind and Weather Conditions: Scaffolding must be designed to withstand strong winds and other weather elements[3].

- Training: Provide adequate training to workers on the safe erection, use, and dismantling of scaffolding[5].

- Emergency Plans: Evacuation plans and procedures must be in place in case of an emergency[3].

The Evolving Role of Technology in Scaffolding

Technological advancements are continuously shaping the scaffolding industry, offering innovative solutions that enhance safety, efficiency, and precision.

- Real-time Monitoring Systems: These systems use sensors and data analytics to monitor the structural integrity of scaffolding in real-time, providing early warnings of potential issues.

- Building Information Modeling (BIM): BIM allows for the creation of detailed 3D models of scaffolding systems, enabling better planning, coordination, and clash detection.

- Drones: Drones can be used to inspect scaffolding from a safe distance, providing high-resolution images and videos that can be used to identify potential problems.

Conclusion

Selecting the right scaffolding system for a high-rise building requires careful consideration of various factors, including height, accessibility, wind conditions, space constraints, and safety requirements. Supported scaffolding, suspended scaffolding, and multi-tiered frame scaffolding systems are among the most common choices, each offering unique advantages and limitations. By prioritizing safety, adhering to regulations, and leveraging technological advancements, construction teams can ensure the successful and safe completion of high-rise projects.

FAQ

1. What is the most significant safety risk associated with scaffolding in high-rise construction?

Falls from height are the most significant risk, requiring robust fall protection measures like guardrails, harnesses, and safety nets[2][3].

2. How often should scaffolding be inspected on a high-rise construction site?

Regular inspections and maintenance of scaffolding are essential to detect any signs of wear or instability[5]. Implementing real-time monitoring systems can help track structural integrity[5].

3. What type of training should workers receive before working on high-rise scaffolding?

Workers should receive adequate training on the safe erection, use, and dismantling of scaffolding[5].

4. How can technology improve scaffolding safety and efficiency in high-rise construction?

Real-time monitoring systems, Building Information Modeling (BIM), and drones can enhance safety, efficiency, and precision in scaffolding operations.

5. What are the key considerations when designing a scaffolding system for a high-rise building?

Key considerations include load-bearing capacity, fall protection measures, anchoring, and compliance with safety regulations[4].

Citations:

[1] https://www.scaffoldinghub.in/blogs/all-blogs/case-study-how-scaffolding-enabled-a-high-rise-project

[2] https://www.canadasafetytraining.com/Safety_Blog/scaffolding-hazard-safety-practices.aspx

[3] https://peakscaffolding.ca/scaffolding-for-toronto-high-rises/

[4] https://aboveallsolutions.com.au/scaffolding-design-for-high-rise-buildings-general-safety-considerations/

[5] https://justscaffolders.com/scaffolding-in-high-rise-construction-challenges-and-solutions/

[6] https://www.ihsa.ca/rtf/health_safety_manual/pdfs/equipment/Scaffolds.pdf

[7] https://www.alibaba.com/showroom/scaffolding-for-high-rise-building.html

[8] https://www.scaffoldingsolutions.com/articles/11-scaffolding-safety-tips/